Square wave and sine wave integrated control system for magnetic suspension permanent magnet motor

A permanent magnet motor and control system technology, applied in the control system, AC motor control, general control strategy, etc., can solve the problem of reducing the falling speed of the magnetic levitation motor, and achieve the effects of enhancing system reliability, easy debugging, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

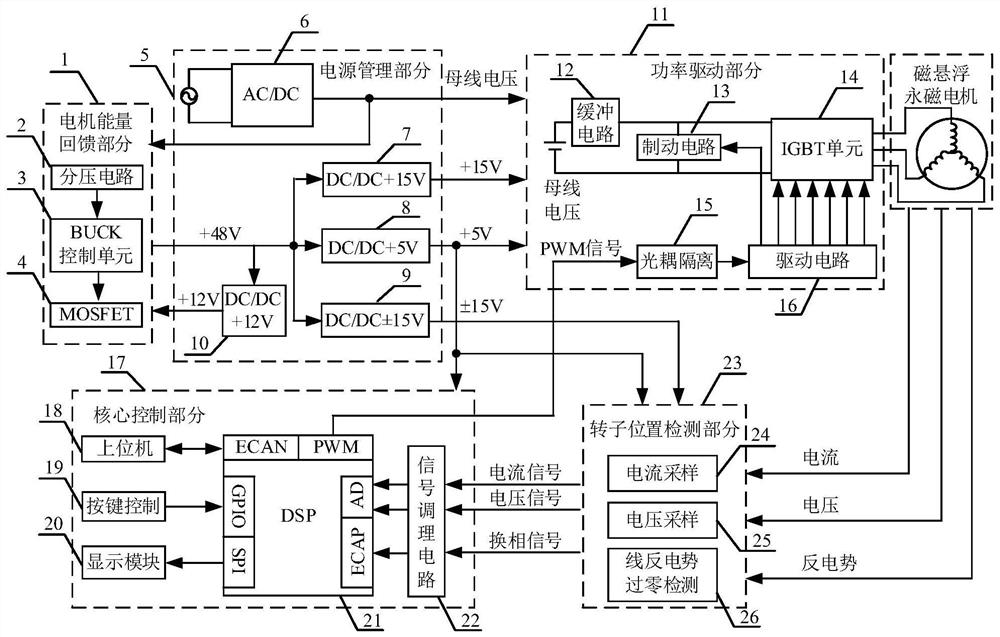

[0027] like figure 1 Shown is a block diagram of the system structure of the present invention, including a core control part 17 , a power drive part 11 , a rotor position detection part 23 , a motor energy feedback part 1 and a power management part 5 . The power management part 5 is responsible for providing strong and weak currents of the entire control system to ensure the normal operation of the system. The motor energy feedback part 1 is not only responsible for the supply of the weak power supply in the power management part during normal operation, but also undertakes the power-off protection function, that is, when the total power supply suddenly fails, the energy fed back to the bus by the motor is used to obtain the same energy as that during normal operation. Voltage, to output continuous voltage for the control system to avoid the accident that the magnetic suspension bearing falls at high speed due to sudden power failure. The rotor position detection part 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com