A drilling simulation device

A simulation device and drilling technology, applied in the field of drilling simulation device, can solve the problem of uneven pressure of the device, and achieve the effect of good protection and good simulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

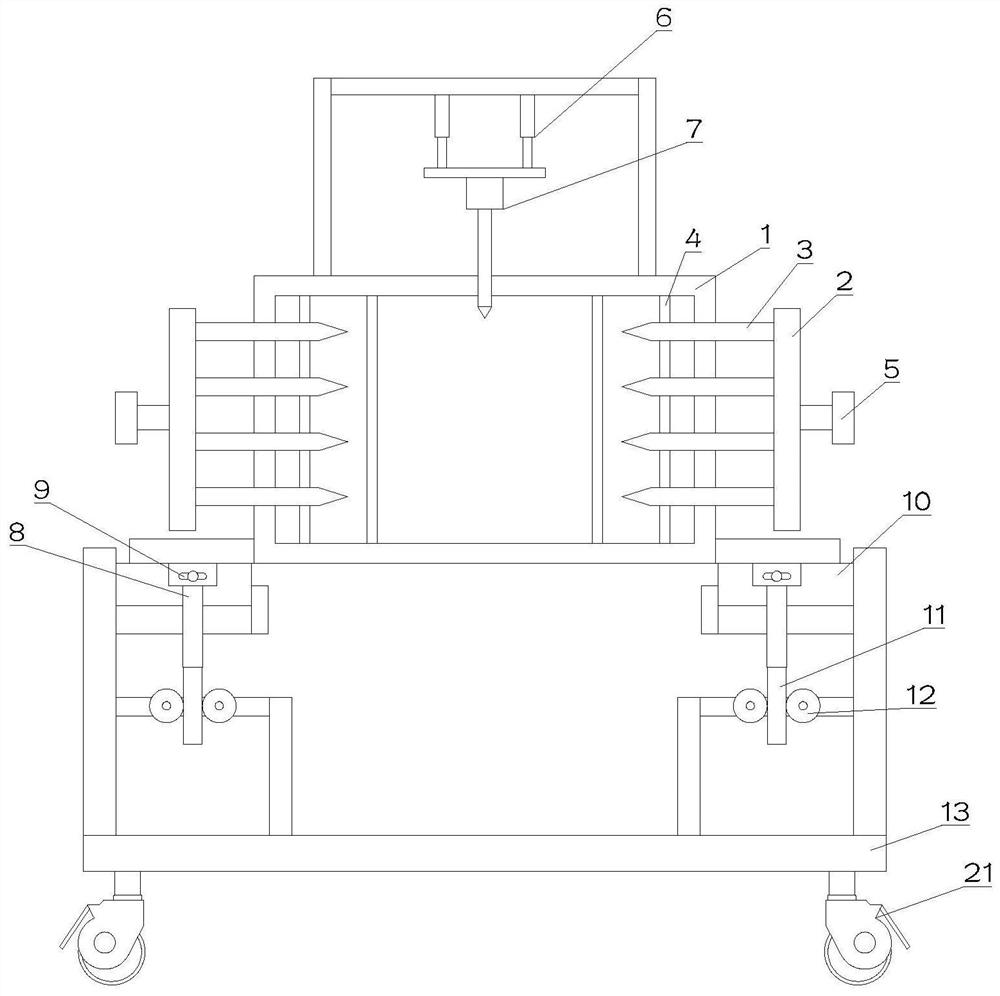

[0027] see figure 1 , In Embodiment 1 of the present invention, it is a structural diagram of a drilling simulation device provided by the embodiment of the present invention, including: a simulation box 1, the interior of which is filled with simulated rock and soil;

[0028] A movable base 13, a shock absorption mechanism is set between the base 13 and the simulation box 1, so as to reduce the vibration during the movement;

[0029] The simulated drilling components are fixedly installed on the simulation box 1;

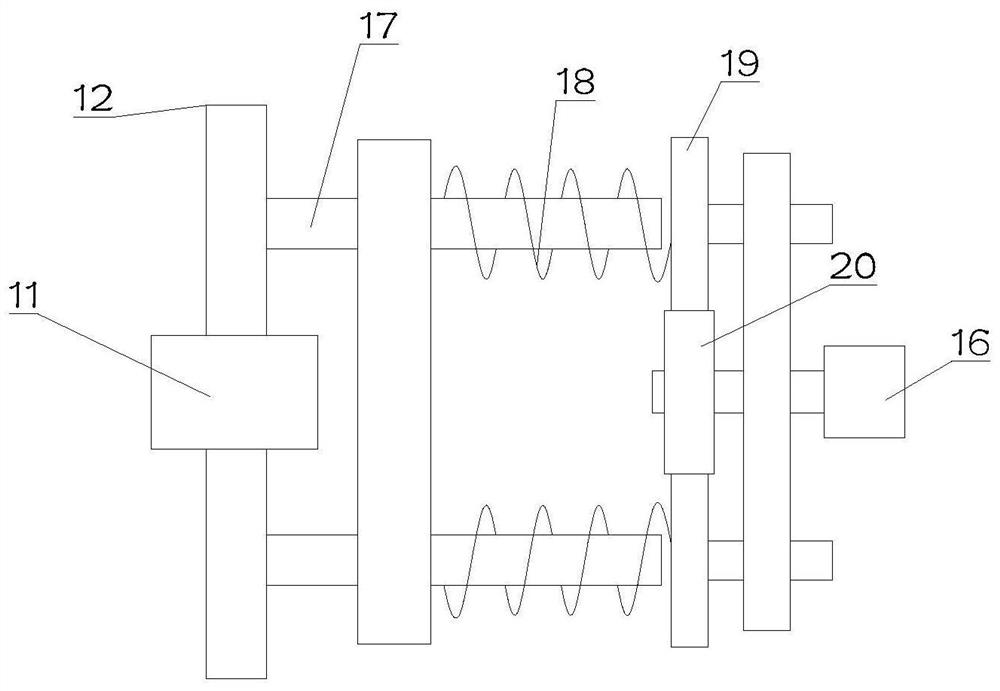

[0030] And, a first regulating part for changing the internal pressure of the simulation box 1; the first regulating part comprises two pressure plates 2 arranged on both sides of the simulation box 1 and capable of moving in the same direction or in the opposite direction at the same speed. A plurality of pressure rods 3 are fixedly installed in an array on the upper part 2 , and the pressure rods 3 are arranged inside the simulation box 1 through the through hol...

Embodiment 2

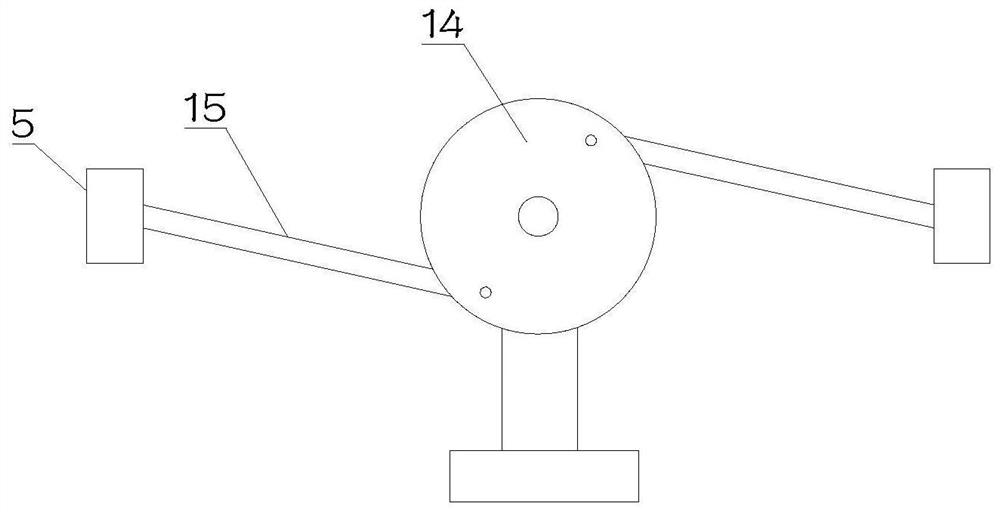

[0034] see figure 1 , 3 And 4, the main difference between this embodiment 2 and embodiment 1 is that in order to drive the pressure plates 2 on both sides to approach at the same speed and in the same direction, the simulation box 1 is still provided with a driving component, and the driving component includes a rotating installation on the simulation box. The drive plate 14 on the 1, the drive plate 14 is self-rotating, the drive plate 14 is symmetrically provided with two connecting rods 15, the connecting rods 15 are rotatably installed on the driving plate 14, and the connecting rods 15 are far away One end of the drive plate 14 is rotatably mounted on the connecting seat 5, and the connecting seat 5 is fixedly installed on the pressing plate 2. Specifically, when the driving plate 14 rotates, the connecting rods 15 on both sides are driven to drive the connecting seat 5 to drive the pressing plate 2 to move. The moving distances of the side links 15 are the same, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com