Equipment special for detecting and correcting tracking rod of total station

A technology of total station and equipment, applied in instruments, measuring instruments, measuring devices, etc., can solve the problems of lateral and calibration functions not being provided, and achieve the effect of being easy to carry and improving the speed of correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

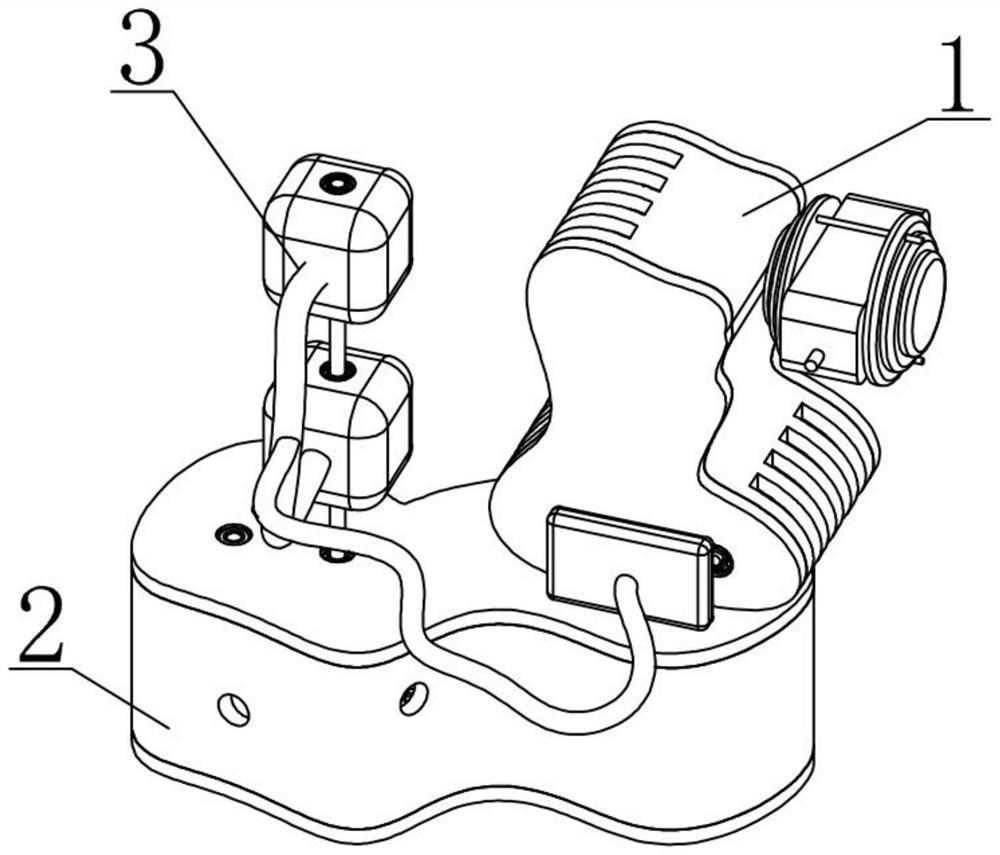

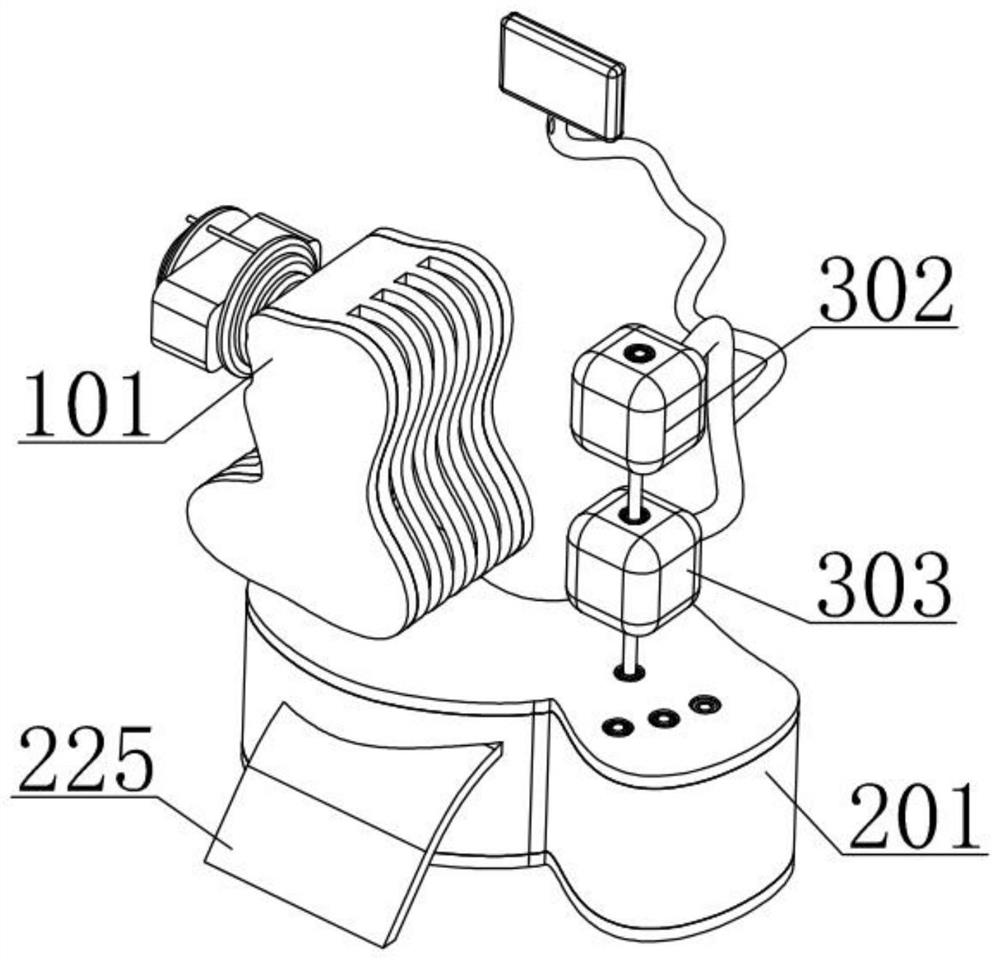

[0023] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The device shown is dedicated to the detection and correction of the tracking rod of the total station, including a correction device 1 , a detection and positioning device 2 and a calibration device 3 .

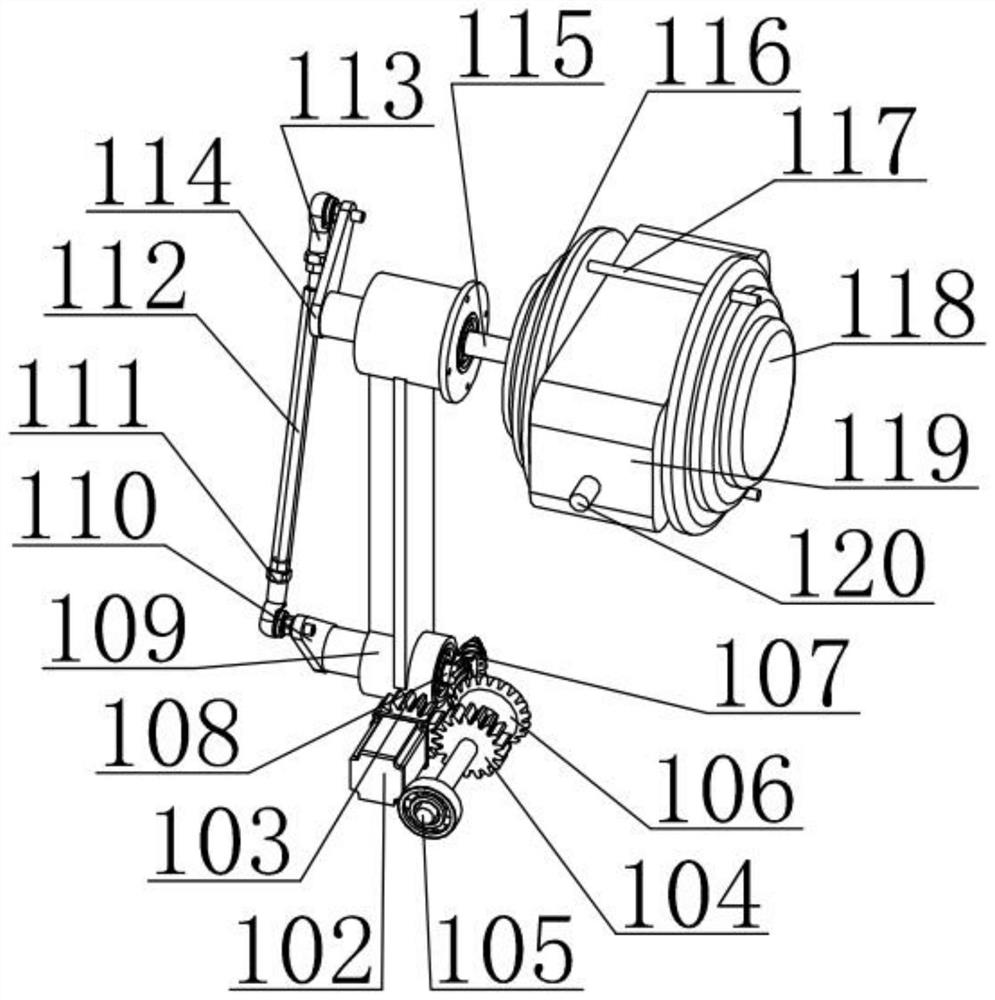

[0024] Correction device 1 includes: correction housing 101; detection and positioning device 2 includes: positioning left drive shaft 216 and positioning bearing plate 224; calibration device 3 includes: marking upper main board 301; The main board 301 is fixedly installed on the positioning left drive shaft 216 .

[0025]The correcting device 1 also includes: correcting the motor 102, correcting the left straight tooth 103, correcting the right transmission shaft 105, correcting the right helical tooth 106, correcting the right helical tooth 107, correcting the right transmission shaft 108, correcting the fixing frame 109, correcting the lower Linkage plate 110, correction lower linkage ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com