A High Ductility Micro-Damage Reinforced Concrete Frame Beam

A technology of reinforced concrete and frame beams, applied in the direction of girders, joists, trusses, etc., can solve the problems of plastic damage, destruction, and failure to continue to use, and achieve the effect of improving the compression capacity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

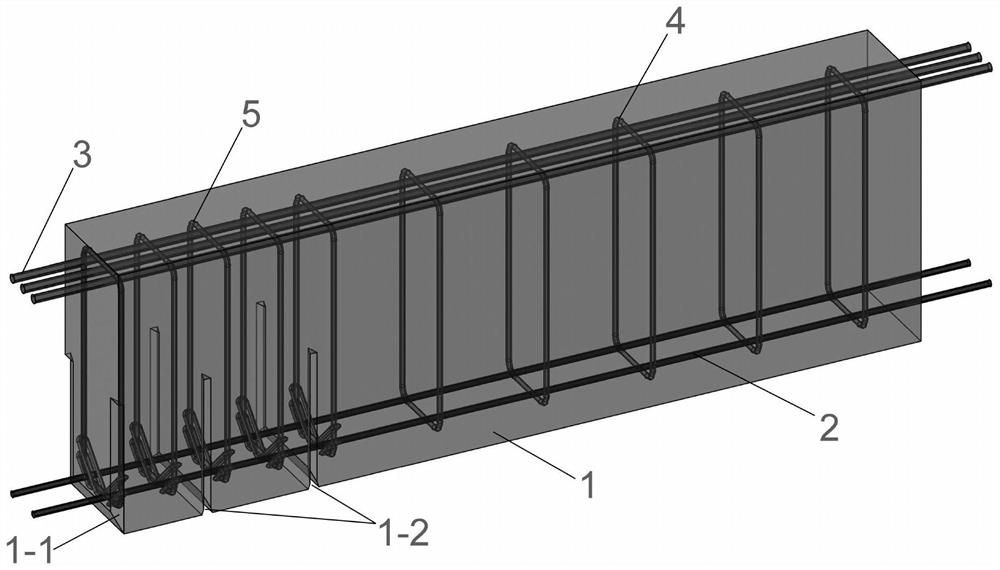

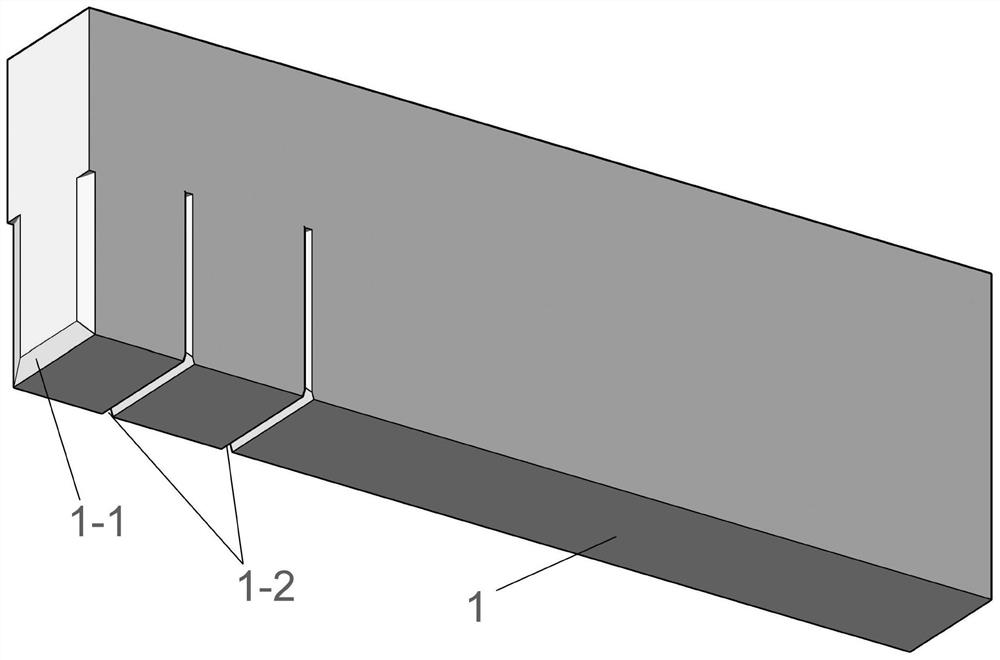

[0031] Embodiment one, as Figure 4 As shown, the application example of the high-ductility slightly damaged reinforced concrete frame beam of the present invention in the cast-in-place reinforced concrete frame structure: in this embodiment, the concrete of the beam concrete 1 and the cast-in-place column 101 is integrally poured, and then by cutting and other means in the Relevant parts of beam concrete 1 form beam end pressure relief groove 1-1 and beam body pressure relief groove 1-2; a plurality of local restraint stirrups 5, common longitudinal reinforcement 2, and high ductility longitudinal reinforcement are arranged at intervals at the end of the frame beam 3. Ordinary stirrups 4 are set as usual, wherein the ordinary longitudinal bars 2 and the high-ductility longitudinal bars 3 are anchored deep into the cast-in-place column 101 .

Embodiment 2

[0032] Embodiment two, such as Figure 5 As shown, the application example of the high-ductility micro-damage reinforced concrete frame beam of the present invention in the assembled integrated reinforced concrete frame structure: in this embodiment, the beam concrete 1 is composed of beam prefabricated concrete 1-3 and beam composite concrete 1-4 Composition, and then together with prefabricated upper column 201, prefabricated lower column 202, post-cast node 203 to form a frame unit. Among them, the beam end pressure relief groove 1-1 and the beam body pressure relief groove 1-2 are formed by cutting the relevant parts of the precast concrete 1-3 of the beam; multiple local restraint stirrups 5 are arranged at intervals at the end of the frame beam , the ordinary longitudinal reinforcement 2, the high ductility longitudinal reinforcement 3, and the ordinary stirrup reinforcement 4 are still set as usual, wherein the ordinary longitudinal reinforcement 2 and the high ductility ...

Embodiment 3

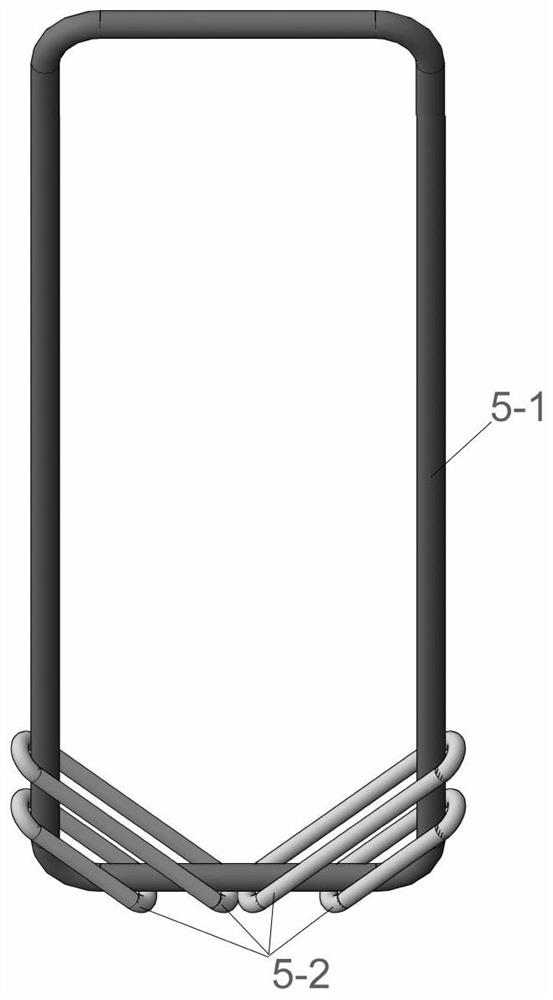

[0033] Embodiment three, as Figure 6 As shown, the application example of the high-ductility micro-damage reinforced concrete frame beam of the present invention in the pre-compression assembled fully prefabricated reinforced concrete frame structure: in this embodiment, the beam concrete 1 and ordinary longitudinal bars 2, ordinary stirrups 4, local constraints Stirrups 5 are integrally prefabricated, and then beam end pressure relief grooves 1-1 and beam body pressure relief grooves 1-2 are formed on relevant parts of beam concrete 1 by cutting or other means; wherein, locally constrained stirrups 5 are closed by large circles 5-1 and closed circular restraint tendons 5-2 are assembled to form ordinary longitudinal reinforcement 2, high ductility longitudinal reinforcement 3, and ordinary stirrup reinforcement 4 according to conventional settings; Pre-pressed connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com