A road bridge crossing device used for water pipes in construction engineering

A technology of construction engineering and water pipes, which is applied in roads, buildings, roads, etc., can solve the problems of easy damage and service life of water pipes, and achieve the effects of improving service life, avoiding crushing, and alleviating rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

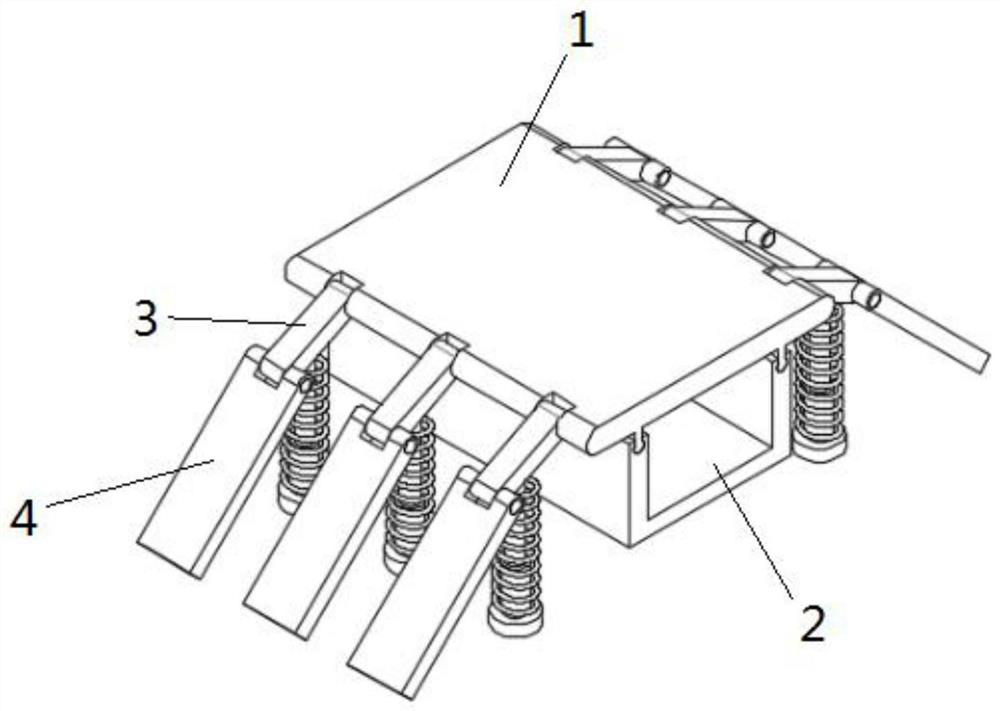

[0032] see Figure 1-6 As shown, a road bridge device for water pipes in construction projects includes a load-bearing mechanism 1, a support seat 2, several buffer linkage mechanisms 3 and connecting plates 4;

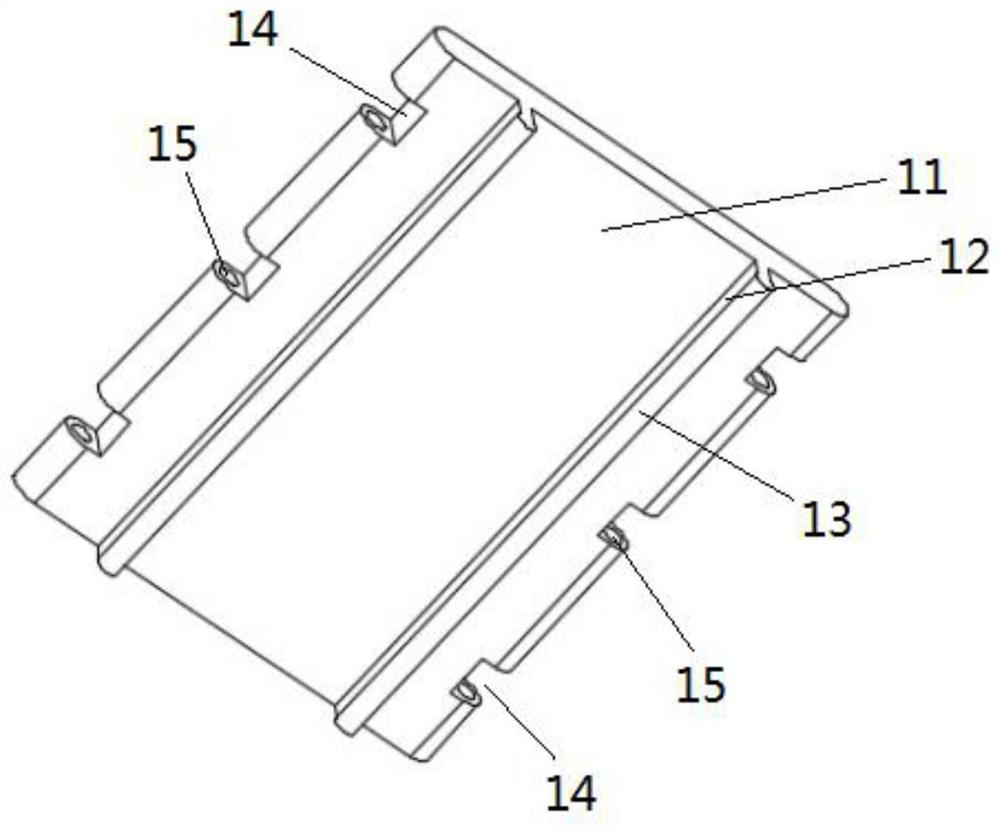

[0033] The carrying mechanism 1 includes a support platform 11, two mutually parallel raised bars 12 are fixed on the lower surface of the support platform 11, and the raised rails 13 are fixed on the raised bars 12, and a plurality of first rectangular grooves 14 are arranged on both sides of the support platform 11. , the distance between two adjacent first rectangular grooves 14 on the same side is the same, and the first hinge holes 15 are opened on both sides of the first rectangular groove 14;

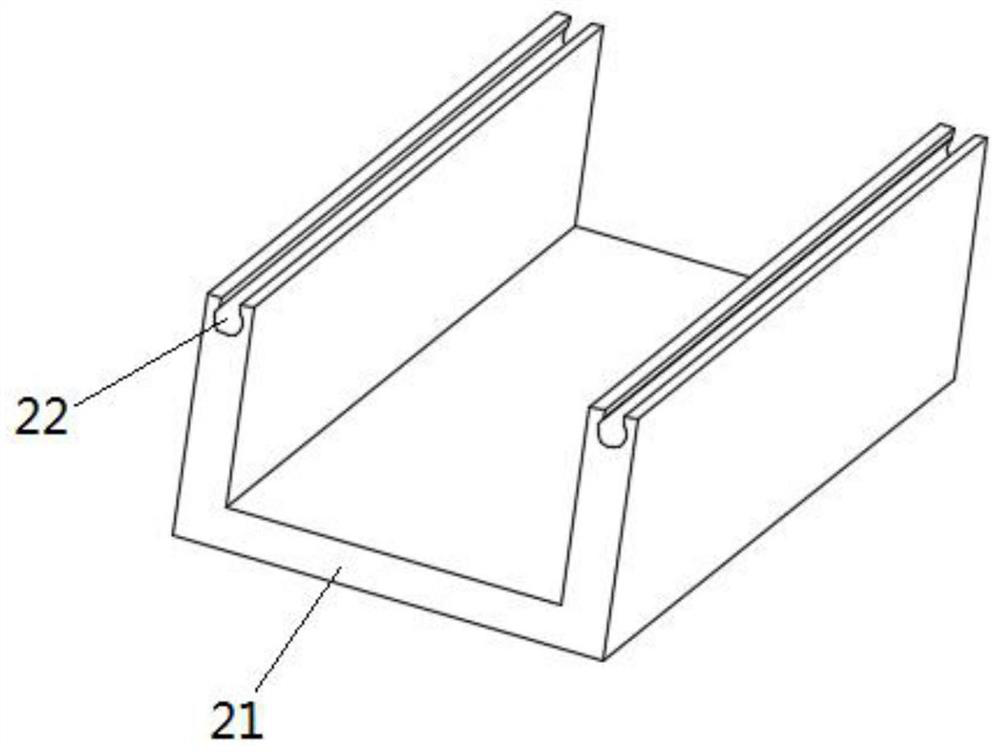

[0034] The support base 2 includes a U-shaped support frame 21, the upper surface of the two ends of the U-shaped support frame 21 is provided with a sliding groove 22 that is slidingly matched with the convex rail 13, the support base 2 moves along the length direction ...

Embodiment 2

[0041] On the basis of Embodiment 1, the shape of the connecting plate is changed, and the auxiliary anti-slip mechanism 6 is added, such as Figure 7-10 As shown, the engaging mechanism 5 includes an engaging plate, the engaging plate 51 is arc-shaped, and the radius of curvature of the arc is larger than the radius of curvature of the automobile tire, and one end of the engaging plate 51 has a third hinge hole 52, and the other end has a fourth hinge hole 53 .

[0042]Auxiliary anti-skid mechanism 6 comprises several anti-skid mechanisms 61 and connecting mechanism 62, and anti-skid mechanism 61 comprises anti-skid plate 611, and the two ends of anti-skid plate 611 two sides are respectively provided with socket hole 612, and connecting mechanism 62 comprises connecting plate 621, and connecting plate 621 two Insertion columns 622 are respectively fixed on the ends, and the insertion columns 622 cooperate with the insertion holes 612 to realize the connection of two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com