Heat-conducting matt black adhesive tape and preparation method thereof

A technology of black tape and adhesive tape, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of increasing the damage probability of components, affecting the service life of components, and not having heat dissipation Function and other issues to achieve the effect of improving thermal conduction, prolonging service life and cycle, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

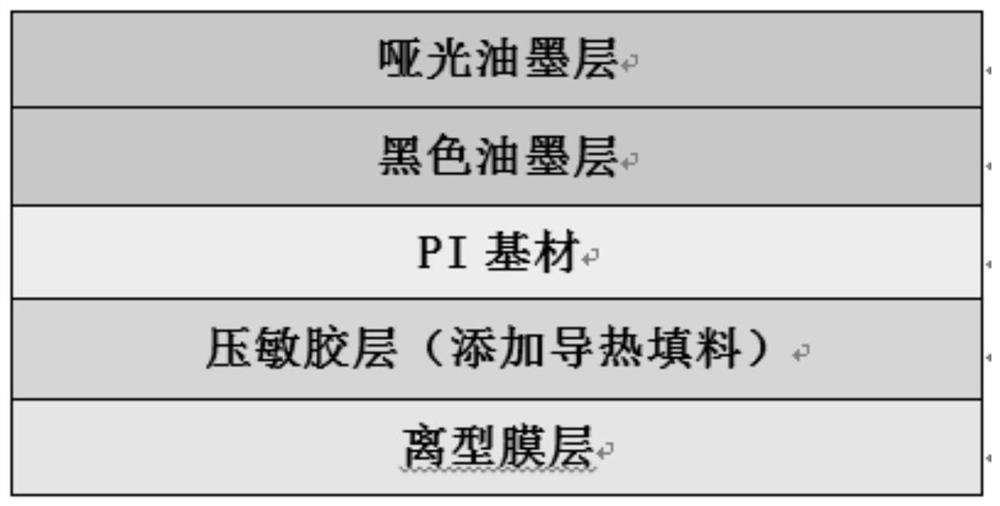

[0034] A thermally conductive matte black adhesive tape, comprising a matte ink layer, a black ink layer, a PI base material layer, a pressure-sensitive adhesive layer and a release film layer added with thermally conductive fillers from the outside to the inside; a matte ink layer, a black ink layer , PI substrate layer, pressure-sensitive adhesive layer added with thermally conductive filler and release film layer have thicknesses of 1 μm, 1 μm, 4.5 μm, 1 μm and 25 μm, respectively.

[0035] Wherein, the matte ink layer is made by mixing the following raw materials: 90 parts of oily matte ink, 2 parts of isocyanate hardener and 15 parts of toluene. The black ink layer is made of the following raw materials: 90 parts of oily black ink, 1 part of isocyanate hardener and 10 parts of toluene. The pressure-sensitive adhesive layer is made of the following raw materials: 90 parts of acrylic pressure-sensitive adhesive, 0.2 part of isocyanate curing agent, 1 part of zinc oxide, and...

Embodiment 2

[0041] A thermally conductive matte black adhesive tape, comprising a matte ink layer, a black ink layer, a PI base material layer, a pressure-sensitive adhesive layer and a release film layer added with thermally conductive fillers from the outside to the inside; a matte ink layer, a black ink layer , PI base material layer, pressure-sensitive adhesive layer added with thermally conductive filler and release film layer have thicknesses of 5 μm, 5 μm, 10 μm, 7 μm and 35 μm, respectively.

[0042] Wherein, the matte ink layer is made by mixing the following raw materials: 95 parts of water-based matte ink, 2 parts of isocyanate hardener and 18 parts of deionized water. The black ink layer is made of the following raw materials: 95 parts of water-based black ink, 1.5 parts of isocyanate hardener and 14 parts of deionized water. The pressure-sensitive adhesive layer is made of the following raw materials: 95 parts of acrylic pressure-sensitive adhesive, 1 part of epoxy curing age...

Embodiment 3

[0048] A thermally conductive matte black adhesive tape, comprising a matte ink layer, a black ink layer, a PI base material layer, a pressure-sensitive adhesive layer added with thermally conductive fillers, and a release film layer from outside to inside; a matte ink layer, a black ink layer , PI base material layer, pressure-sensitive adhesive layer added with thermally conductive filler and release film layer have thicknesses of 2 μm, 4 μm, 7.5 μm, 5 μm and 25 μm, respectively.

[0049] Wherein, the matte ink layer is made by mixing the following raw materials: 100 parts of oily matte ink, 2 parts of isocyanate hardener and 20 parts of ethyl acetate. The black ink layer is made of the following raw materials: 100 parts of oily black ink, 1.5 parts of isocyanate hardener and 15 parts of toluene. The pressure-sensitive adhesive layer is made of the following raw materials: 100 parts of acrylic pressure-sensitive adhesive, 1 part of epoxy curing agent, 25 parts of quasi-spher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com