Surface-functionalized polyphenylene sulfide, solid-liquid two-phase electrolyte and preparation method

A surface-functionalized, polyphenylene sulfide technology, used in non-aqueous electrolyte batteries, circuits, electrical components, etc., can solve the problems of poor room temperature ionic conductivity, poor machining performance, and low organic electrolyte conductivity, etc. No pollution, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

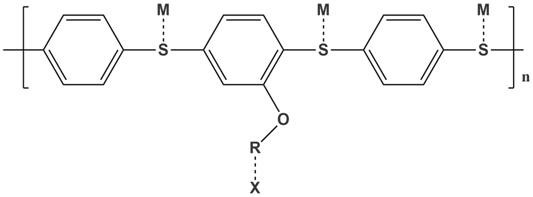

[0017] This embodiment provides a surface-functionalized polyphenylene sulfide. The hydrogen position (—H) on the benzene ring on the long chain of polyphenylene sulfide is replaced by an ether bond (—O—), and the other end of the ether bond is linked to Functionalized molecules (C 6 Cl 4 o 2 ), lithium metal ions are adsorbed on the sulfur site of polyphenylene sulfide. Its structure is as follows:

[0018]

[0019] The preparation method of the polyphenylene sulfide of above-mentioned surface functionalization is as follows:

[0020] Low-temperature powdered polyphenylene sulfide (D50=5 μm), LiCl salt and anion adsorbent C 6 Cl 4 o 2 a homogeneous mixture at 210 o C conditions and under the protection of an inert atmosphere, the sealed heat preservation reaction for 2 h, so that Li + Adsorbed on the sulfur site, C 6 Cl 4 o 2 The oxygen double bond of the molecule opens the link to the benzene ring of polyphenylene sulfide, and at the same time the proton is tra...

Embodiment approach 2

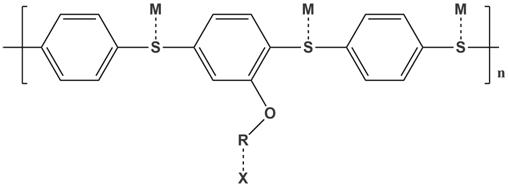

[0024] This embodiment provides a surface-functionalized polyphenylene sulfide. The hydrogen position (—H) on the benzene ring on the long chain of polyphenylene sulfide is replaced by an ether bond (—O—), and the other end of the ether bond is linked to Functionalized molecules (C 8 Cl 2 N 2 o 2 ), sodium metal ions are adsorbed on the sulfur site of polyphenylene sulfide. Its structure is as follows:

[0025]

[0026] The preparation method of the polyphenylene sulfide of above-mentioned surface functionalization is as follows:

[0027] Low-temperature powdered polyphenylene sulfide (D50=10 μm), NaCl salt and anionic adsorbent C 8 Cl 2 N 2 o 2 a homogeneous mixture at 210 o C conditions and under the protection of an inert atmosphere, sealed and heat-preserved for 1 h, so that Na + Adsorbed on the sulfur site, C 8 Cl 2 N 2 o 2 The oxygen double bond of the molecule opens the link to the benzene ring of polyphenylene sulfide, and at the same time the proton i...

Embodiment approach 3

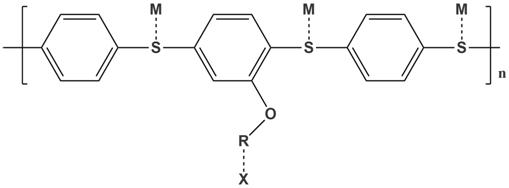

[0031] This embodiment provides a surface-functionalized polyphenylene sulfide. The hydrogen position (—H) on the benzene ring on the long chain of polyphenylene sulfide is replaced by an ether bond (—O—), and the other end of the ether bond is linked to Functionalized molecules (C 9 h 10 o 4 ), and zinc metal ions are adsorbed on the sulfur site of polyphenylene sulfide. Its structure is as follows:

[0032]

[0033] The preparation method of the polyphenylene sulfide of above-mentioned surface functionalization is as follows:

[0034] Low temperature powdered polyphenylene sulfide (D50=5 μm), ZnCl 2 Salt and anion adsorbent C 9 o 4 h 9 a homogeneous mixture at 210 o Under the condition of C and inert atmosphere protection, sealed heat preservation reaction for 0.5 h, so that Zn 2+ Adsorbed on the sulfur site, C 9 o 4 h 9 The oxygen double bond of the molecule opens the link to the benzene ring of polyphenylene sulfide, and at the same time the proton is transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com