Binary polymer biodiesel pour point depressant as well as preparation method and application thereof

A biodiesel and polymer technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as poor fluidity at low temperature, and achieve the effect of small molecular weight of the copolymer, strong compounding of the system, and low price of the monomer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

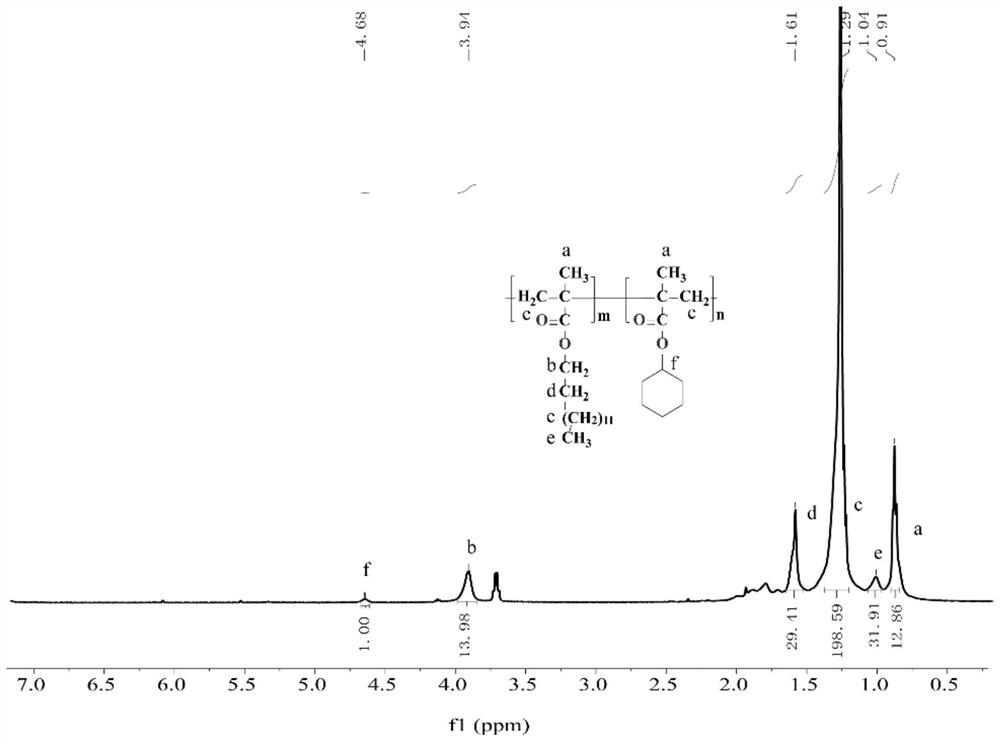

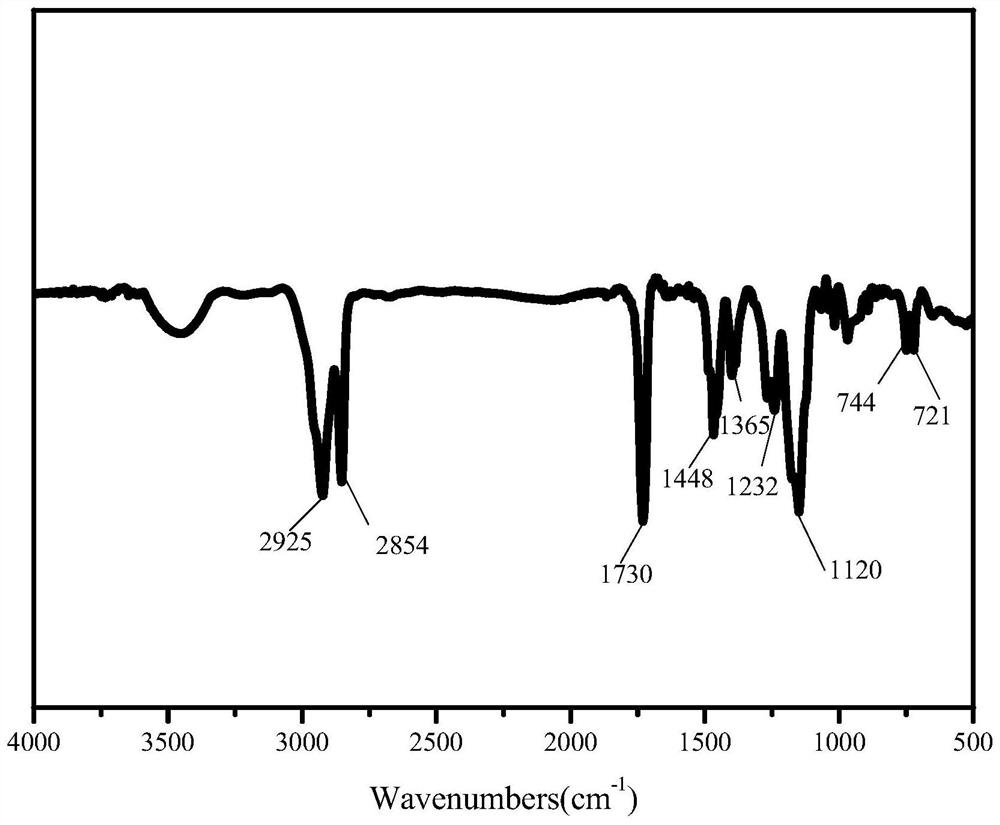

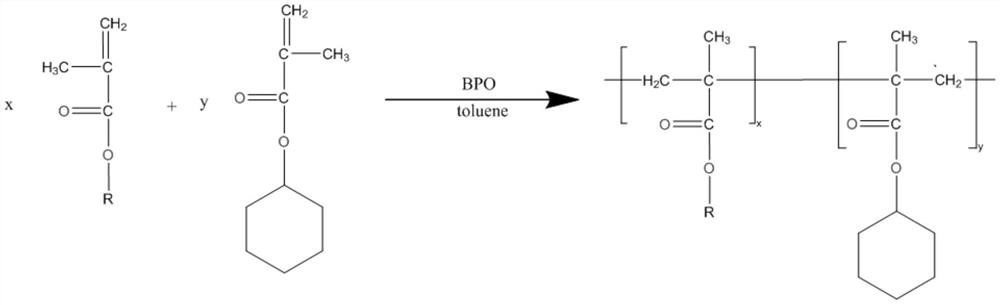

[0028] A kind of binary polymer biodiesel pour point depressant, its preparation method comprises the following steps:

[0029] 1) Add methacrylic acid and higher alcohol to toluene at a molar ratio (0.8-1.2): 1 to prepare a mixed solution of methacrylic acid, heat to 50-70°C and mix evenly, then add the catalyst p-toluenesulfonic acid and Heating to 110-120°C and reacting at a constant temperature for 5-6 hours to obtain higher carbon ester of methacrylate; wherein, the higher alcohol includes at least one of myristyl alcohol, cetyl alcohol or stearyl alcohol, and the amount of catalyst added is 0.6-1.0% of the total mass of methacrylic acid and higher alcohols,

[0030] 2) Add high carbon methacrylate and cyclohexyl methacrylate to toluene at a molar ratio (4-7): 1, then heat up to 60°C, and fully stir to dissolve all reactants, while nitrogen Pumping 3 times to remove the air in the reaction system to obtain a reaction system solution;

[0031] 3) Heat the reaction system...

Embodiment 1

[0035] A kind of myristyl methacrylate-cyclohexyl methacrylate binary polymer, its preparation method comprises the following steps:

[0036] 1) Add 10.33g (0.12mol) of methacrylic acid, 21.44g (0.1mol) of tetradecyl alcohol, and 0.192g of terephthalic acid to a three-necked flask equipped with a condenser, a water separator, a thermometer, and a magnetic stirring device. Phenol and 50mL toluene, then heated up to 60°C and stirred thoroughly to completely dissolve myristyl alcohol in toluene to obtain a mixed raw material solution;

[0037] 2) quickly add 0.254g catalyst p-toluenesulfonic acid, and heat reaction at 120 DEG C for 5h, when it is observed that the amount of water in the water separator is equivalent to the theoretical value, the reaction is terminated to obtain a light yellow transparent liquid reaction product solution;

[0038] 3) After the reaction product solution is cooled to room temperature, pour it into a separatory funnel, wash it with 5% NaOH solution f...

Embodiment 2

[0046] A cetyl methacrylate-cyclohexyl methacrylate binary polymer, in its preparation method:

[0047] In step 1), adopt 24.24g cetyl alcohol to replace 21.44g tetradecyl alcohol;

[0048] In step 2), the add-on of catalyst p-toluenesulfonic acid is 0.277g;

[0049] In step 4), 15.53 g (0.05 mol) of hexadecyl methacrylate was used to replace 14.12 g (0.05 mol) of tetradecyl methacrylate;

[0050] Step 5) in, the add-on of benzoyl peroxide is 0.172g.

[0051]All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com