A kind of recycled concrete with anti-permeability and preparation method thereof

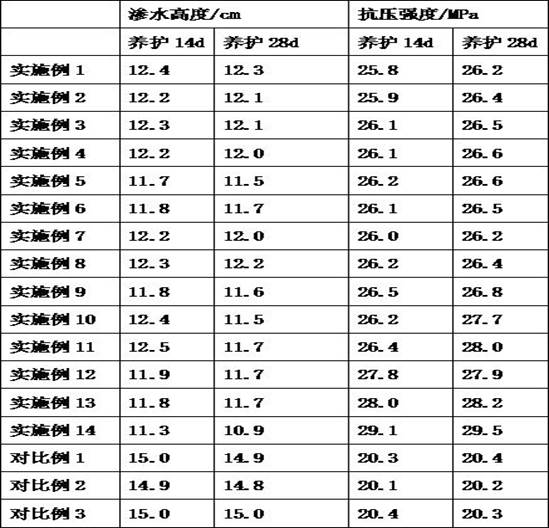

A technology of recycled concrete and impermeability, applied in the field of concrete, can solve the problems that restrict the wide application of recycled aggregates, large porosity, low impermeability strength and compressive strength, etc., and achieve reduced water migration, compact structure, and impermeability Good performance and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

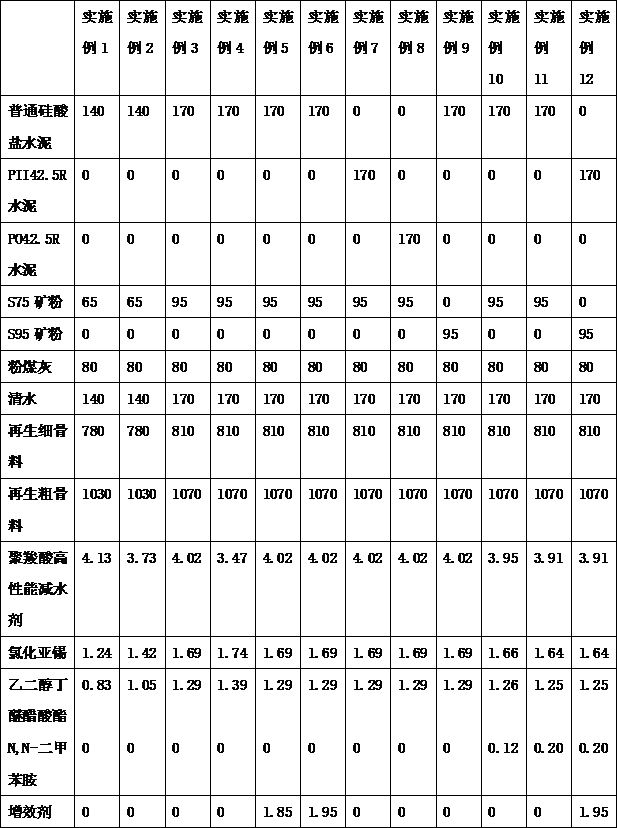

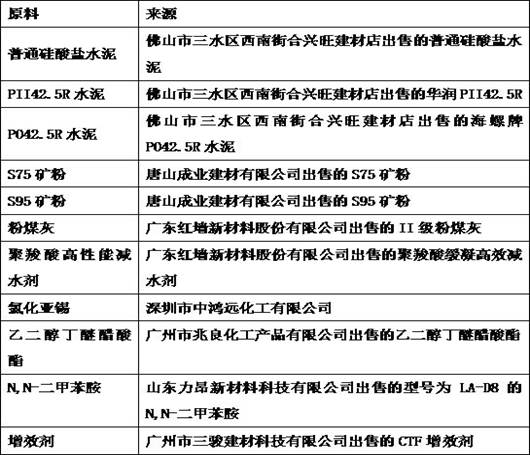

[0044] Examples 1-12 disclose a reclaimed concrete with impermeability, which is prepared from the components of the mass in Table 2, unit: Kg.

[0045] Cement, mineral powder, fly ash, water, recycled fine aggregate, recycled coarse aggregate, admixture.

[0046] The admixtures include polycarboxylate superplasticizer, stannous chloride, ethylene glycol butyl ether acetate and N,N-xylidine.

[0047] Table 2

[0048]

Embodiment 1、2

[0049] A kind of preparation method of regenerated concrete with impermeability in embodiment 1,2 is:

[0050] Step 1), adding the regenerated fine aggregate, regenerated coarse aggregate, fly ash, mineral powder and admixture together into the mixer for stirring, the rotating speed is 20 r / min, and stirring for 20 s to obtain the first preparation material;

[0051] Step 2), add water and cement into the mixer and mix together with the first preparation material, the rotating speed is 30 r / min, and the mixing is performed for 30 s. After compacting and molding, the recycled concrete with impermeability is obtained.

Embodiment 3-12

[0052] A kind of preparation method of regenerated concrete with impermeability in embodiment 3-12 is:

[0053] Step 1), adding the regenerated fine aggregate, regenerated coarse aggregate, fly ash, mineral powder and admixture together into the mixer for stirring, the rotating speed is 30 rpm, and stirring for 40 s to obtain the first preparation material;

[0054] Step 2), adding water and cement into the mixer and mixing with the first preparation material at a rotational speed of 35 rpm, stirring for 50 s, and obtaining impermeable recycled concrete after compacting and forming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com