Low-temperature stirring evaporation equipment

An evaporation equipment and low-temperature technology, applied in the field of low-temperature stirring evaporation equipment, can solve problems such as uneven heating, low heating efficiency, and insufficient heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0028] It should be noted that terms such as "upper", "lower", "left", "right", "inner" and "outer" in the present invention are only used to describe the present invention with reference to the accompanying drawings, and are not used as limiting terms.

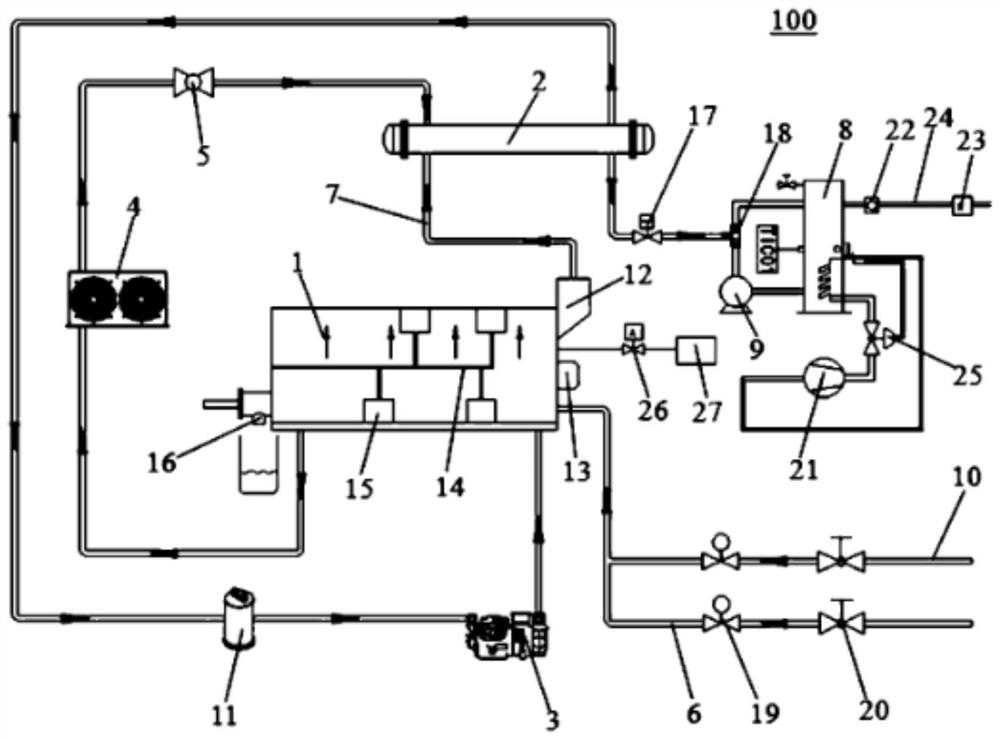

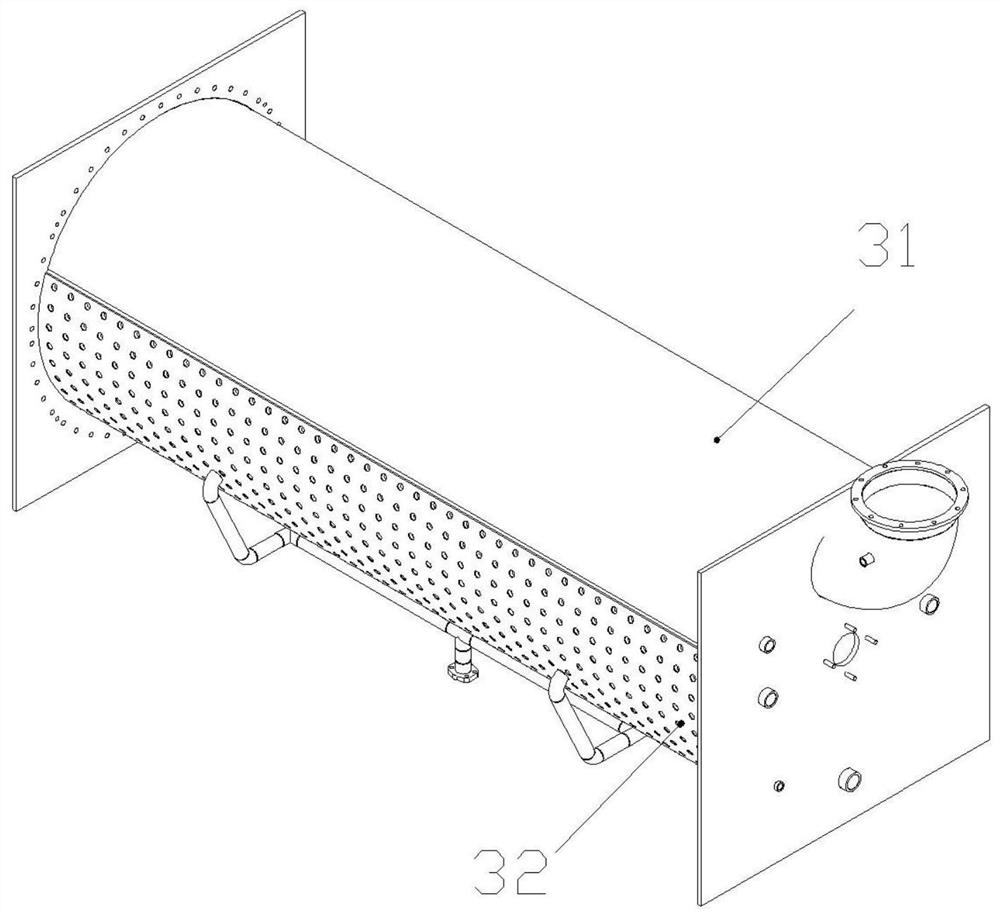

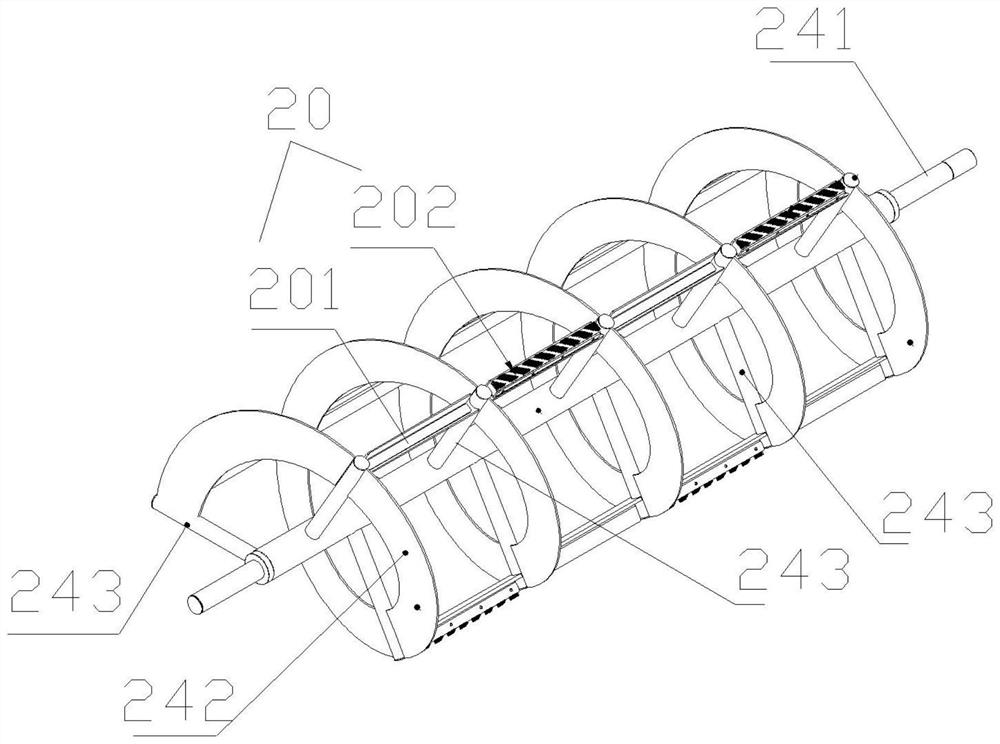

[0029] Please refer to Figure 1 to Figure 3 , the present embodiment is a low-temperature steam evaporation device 100, which includes an evaporator 1, a condensed water container 2 forming a circulation loop with the evaporator 1, a compressor 3, and a condensing device arranged on the pipeline from the evaporator 1 to the condensed water container 2. Fan 4 and expansion valve 5, steam input pipe (unlabeled) for transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com