Anti-blocking self-cleaning injection molding glue injection equipment

An injection molding and self-cleaning technology, applied in the field of injection molding, can solve the problems of slow blanking, mismatched supply, and reduced plastic stickiness, and achieve the effect of solving slow blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

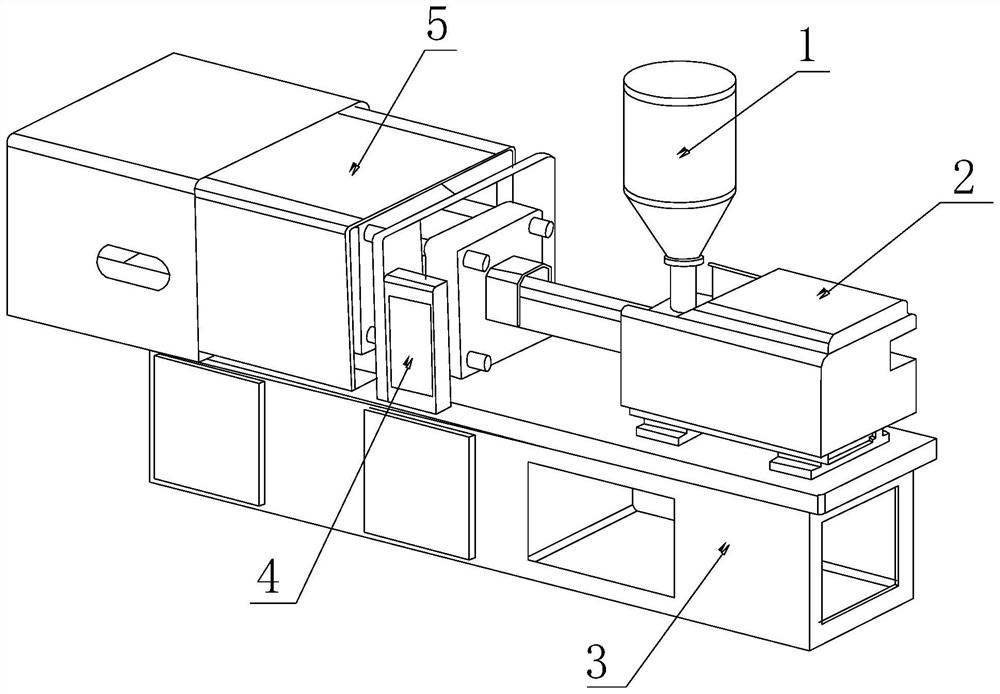

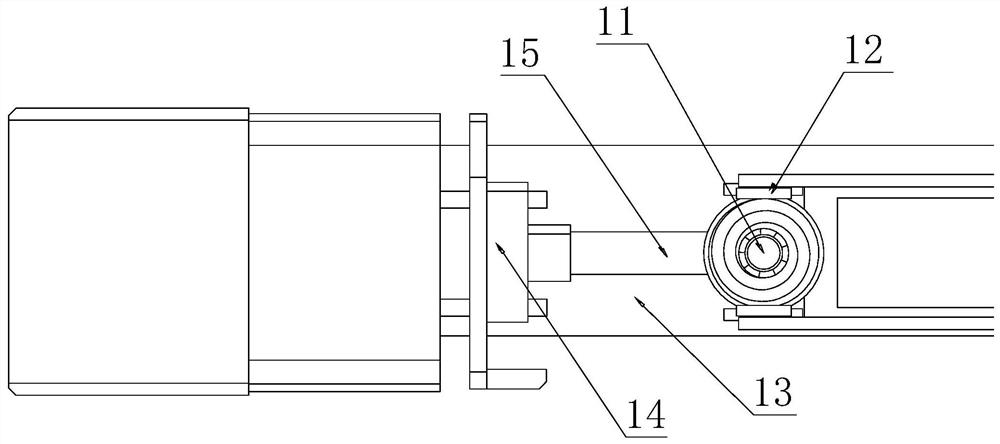

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] Its structure includes a chute 1, an equipment box 2, a carrier 3, a controller 4, and an injection molding chamber 5. The bottom of the hopper 1 is welded to the surface of the equipment box 2, and the equipment box 2 is bolted to the upper end of the carrier 3. fixed, the upper end of the carrier 3 is bolted to the injection molding bin 5, the right side of the injection molding bin 5 is hingedly connected to the controller 4, the controller 4 is matched with the internal clearance of the equipment box 2, and the lower chute 1 includes a lower Plastic port 11, clamping block 12, workbench 13, mold block 14, conveying pipe 15, both sides of the lower plastic port 11 are engaged with the clamping block 12, and the left side of the lower plastic port 11 is in clearance fit with the conveying pipe 15 , the conveying pipe 15 is in clearance fit with the surface of the workbench 13, the conveying pipe 15 is movably ...

Embodiment 2

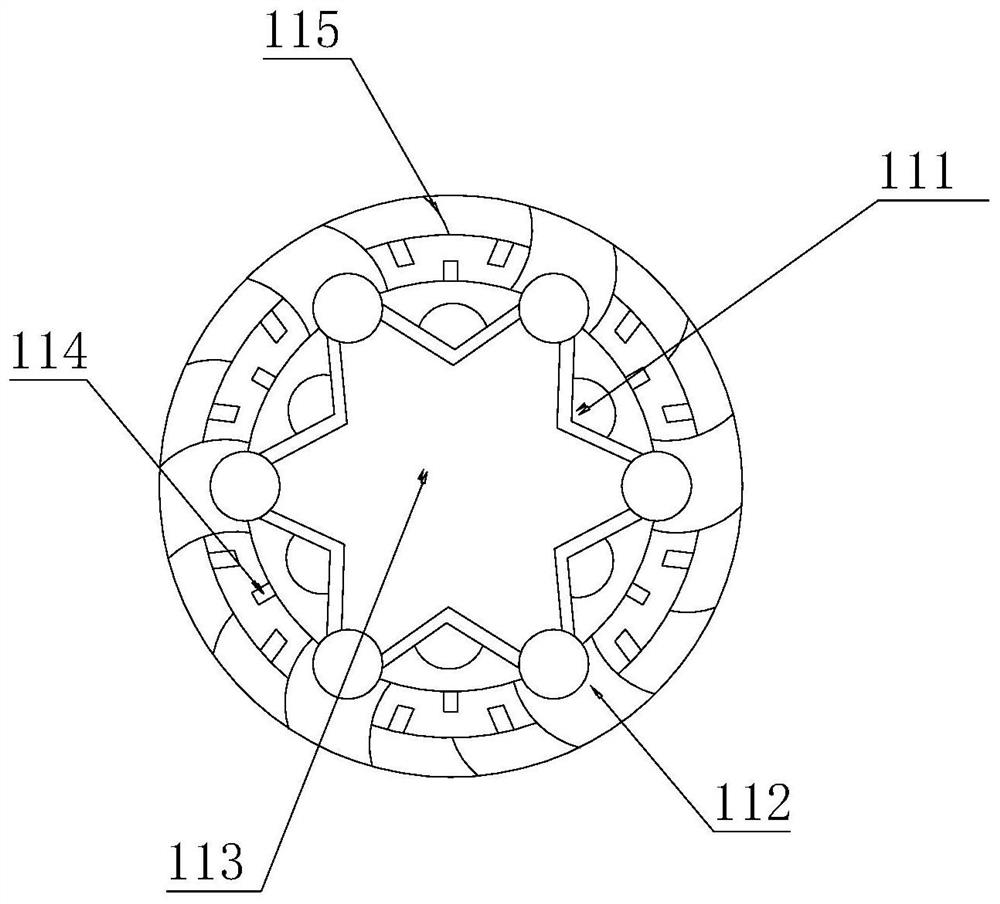

[0034] as attached Image 6 to attach Figure 7 Shown:

[0035] Wherein, the pendulum piece a11 includes an impact block b1, an elastic cord b2, a sliding chamber b3, a limit rod b4, and a strike chamber b5, the strike block b1 is movably matched with the strike chamber b5, and the strike chamber b5 Cooperate with the top of the sliding chamber b3 with a gap, the two sides of the sliding chamber b3 are embedded and connected with the limit rod b4, the limit rod b4 is movably matched with the surface of the elastic rope b2, and the elastic rope b2 is embedded with the inside of the impact block b1 connection, the impact block b1 is provided with six pieces, which are distributed on the inner side of the two walls of the limit rod b4 to limit its movable distance, and the rear end is embedded and connected with the elastic rope b2, wherein the impact block b1 is conducive to melting together at the bottom by impact The plastic is crushed to avoid the hole at the entrance becomin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com