Aeration system of energy-saving homogenizing tank

An aeration system and aeration tube technology, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of increased process energy consumption, difficulty in feeding mud into the feed pump, and short time, etc., to achieve improved The effect of process production efficiency, saving engineering cost and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

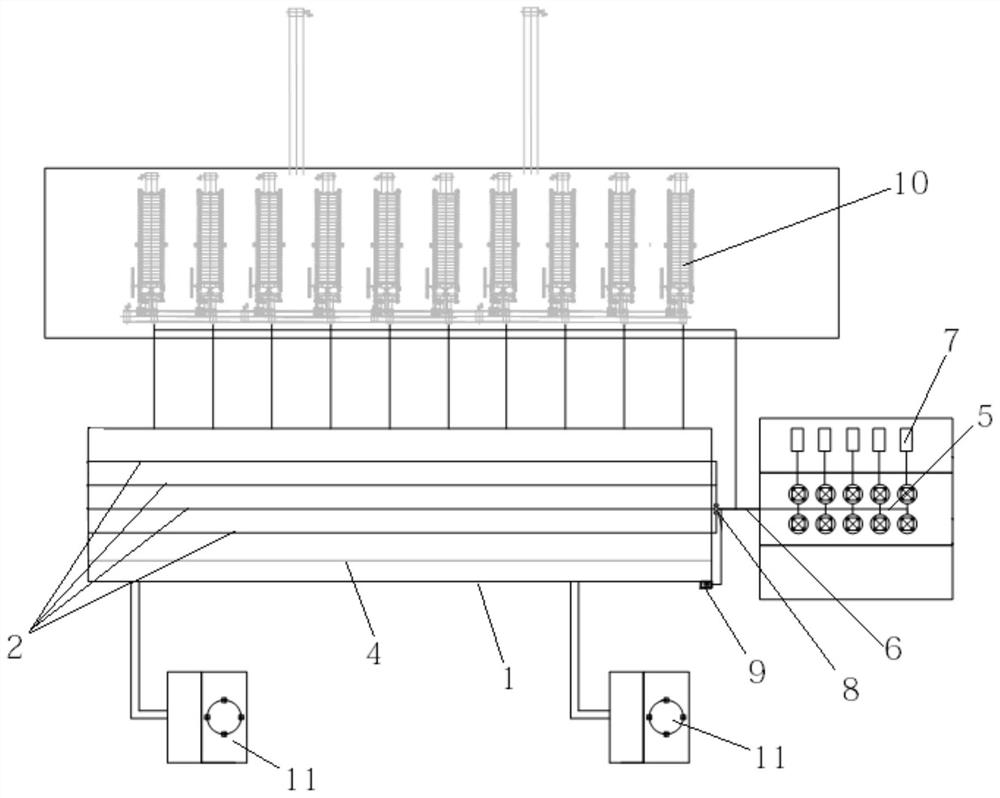

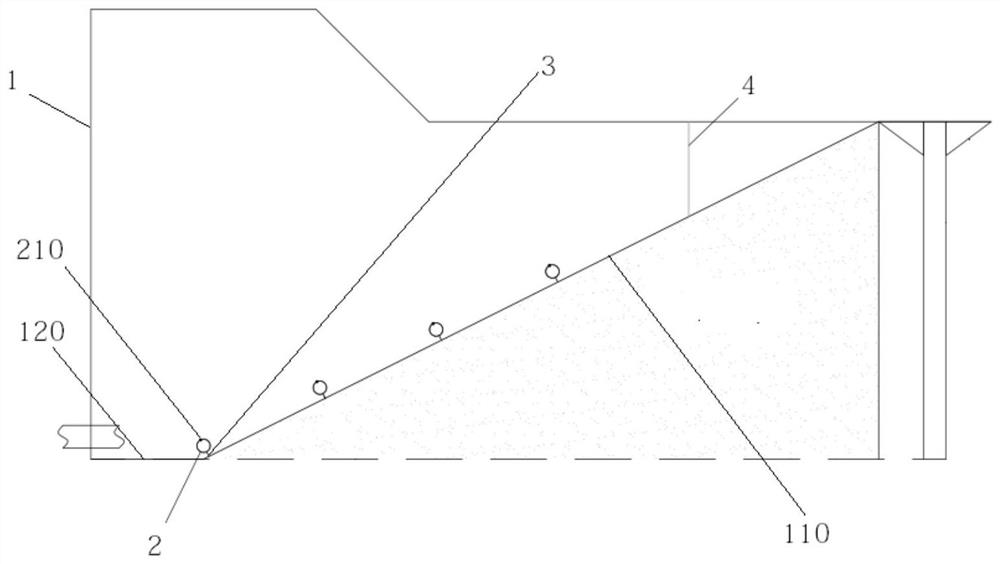

[0026] Such as Figure 1 ~ Figure 2 As shown, an energy-saving homogenization tank aeration system includes a homogenization tank 1 and an aeration pipe 2. The angle between one of the side walls of the homogenization tank 1 and the bottom 120 of the tank is greater than 90° to form a slope surface 110, According to the range shown in the figure, the angle between the right side wall of the homogenization tank 1 and the bottom 120 of the pool is greater than 90° to form a slope surface 110, and the bottom 120 of the pool is a plane, and the slope surface 110 is pressed along its inclination direction. There are a plurality of aeration pipes 2 arranged at preset intervals, each aeration pipe 2 is provided with aeration holes 210 according to preset intervals, and the feed pipe mouth of the plate and frame machine 10 is opposite to the slope surface 110 through the homogenization tank 1 The side wall extends into the homogenization tank 1.

Embodiment 2

[0028] Such as Figure 1 ~ Figure 2 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1, which is specifically as follows:

[0029] The lowermost aeration pipe 2 is at the bottom of the slope surface 110 .

Embodiment 3

[0031] Such as Figure 1 ~ Figure 2 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1 or 2, which is specifically as follows:

[0032] The aspect ratio of the slope surface 110 is 1:1.5-1:2.5, preferably 1:2; the width of the pool bottom 120 is 0.5-1m, preferably 1m, which makes it easier for the sludge to flow to the feed nozzle of the plate and frame machine .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com