Automatic feeding heat energy garbage treatment machine

A technology of automatic feeding and garbage disposal, which is applied to the removal of solid waste, etc., can solve problems such as inconsistency of scientific and technological concepts, inability to automatically feed materials, and crude feeding units, and achieve the effects of simple and reliable structure, slow feeding, and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

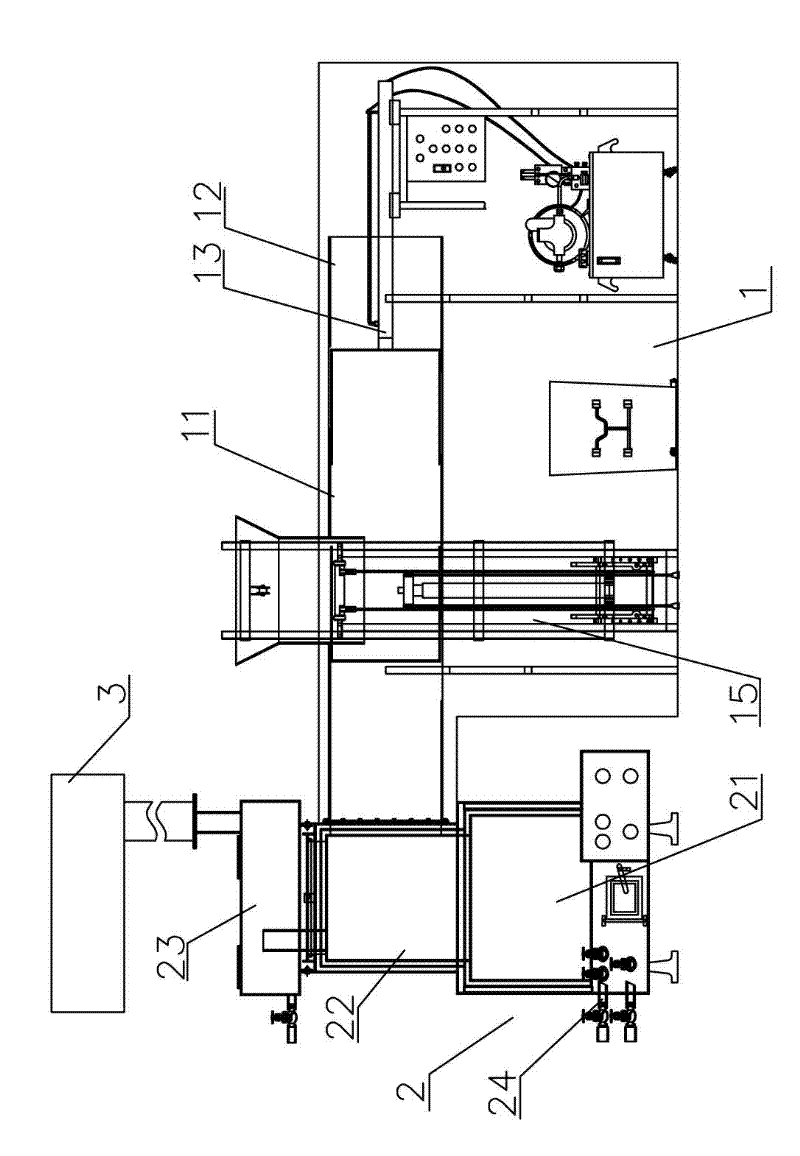

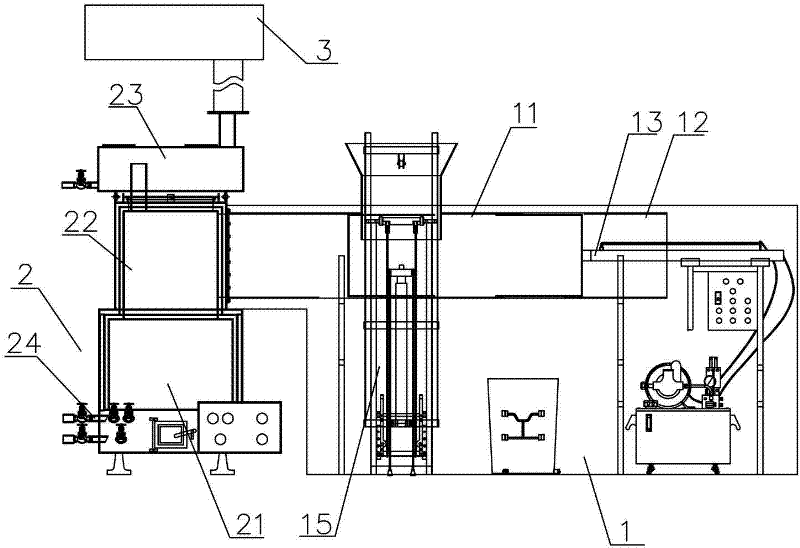

[0015] refer to figure 1 , an automatic feeding heat energy garbage disposer, comprising a feeding unit 1, a thermal energy decomposition unit 2 and an exhaust gas treatment unit 3 connected in sequence, the feeding unit 1 comprising at least one delivery pipeline 12 with a feed inlet 11, the delivery pipeline One end of 12 is connected with the thermal energy decomposition unit 2, and the other end is provided with a piston push rod 13.

[0016] As a further preferred embodiment, the feed inlet 11 is located in the middle of the conveying pipeline 12, and a material lifting frame 15 is arranged beside it. Specifically, the material lifting frame 15 has a hook, and the trash can can be hooked on the frame, and then driven by a motor, the material lifting frame 15 can automatically lift the trash can to the feed port 11 to dump garbage.

[0017] As a further preferred embodiment, the feeding unit 1 further includes a hydraulic power system coupled with the piston push rod 13 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com