Hydraulic key puller and key pulling method using same

A hydraulic and puller technology, applied in the fields of transportation, machinery, electricity, construction, and engineering, can solve the problems of poor control of the drawing center, unreliable fixtures, low work efficiency, etc., to achieve good economic benefits and eliminate potential safety hazards , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

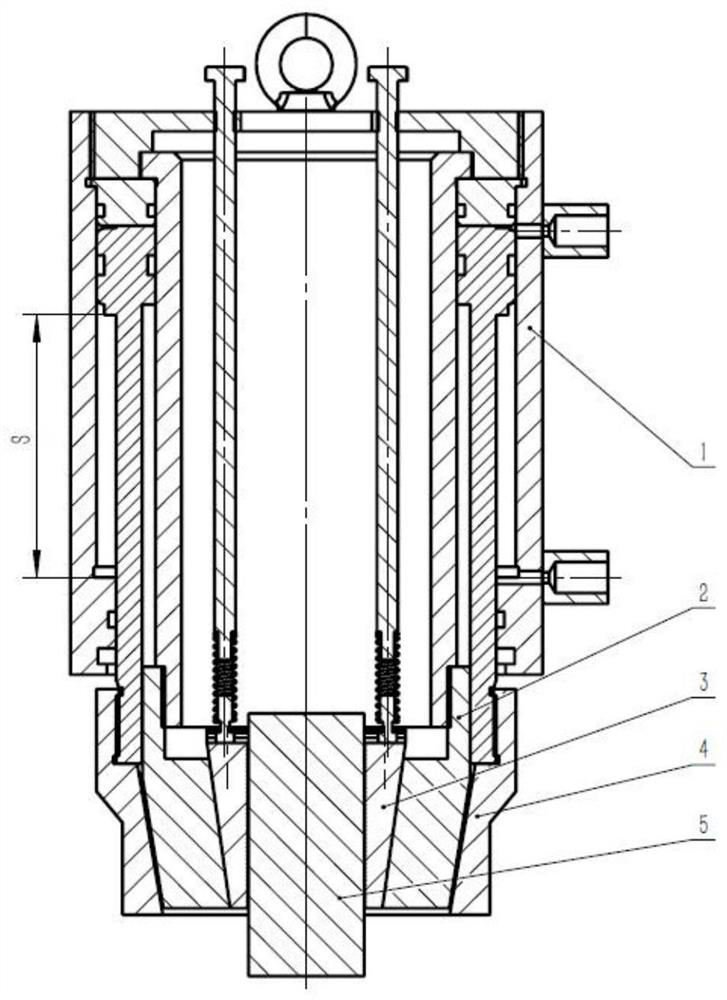

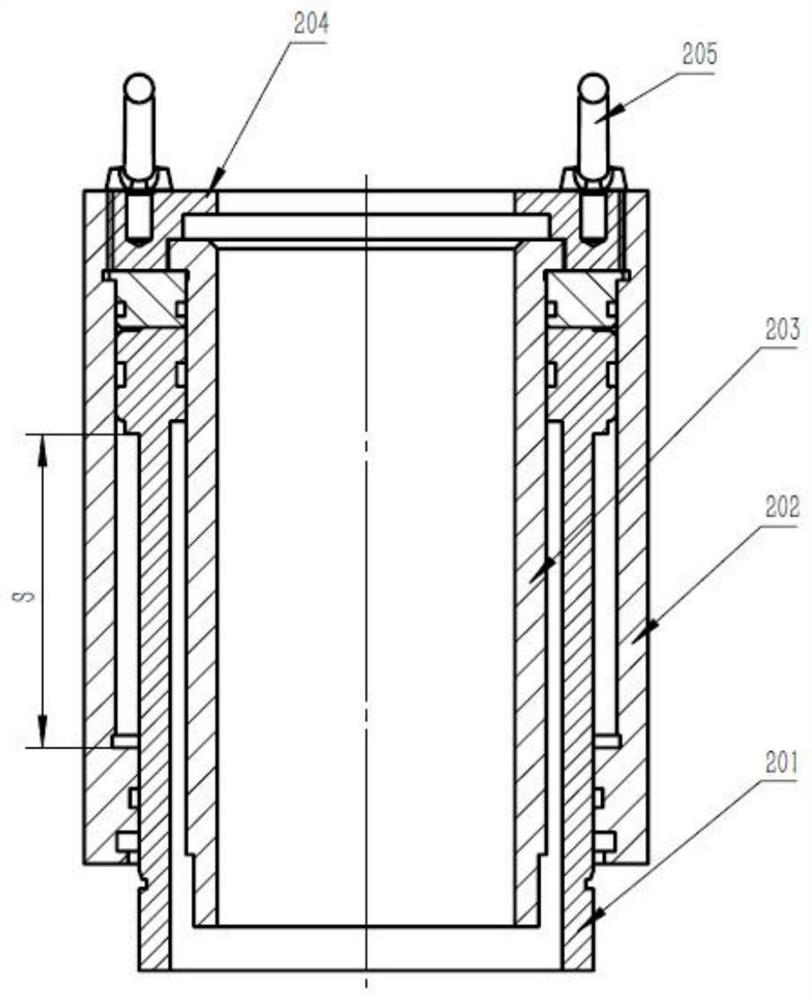

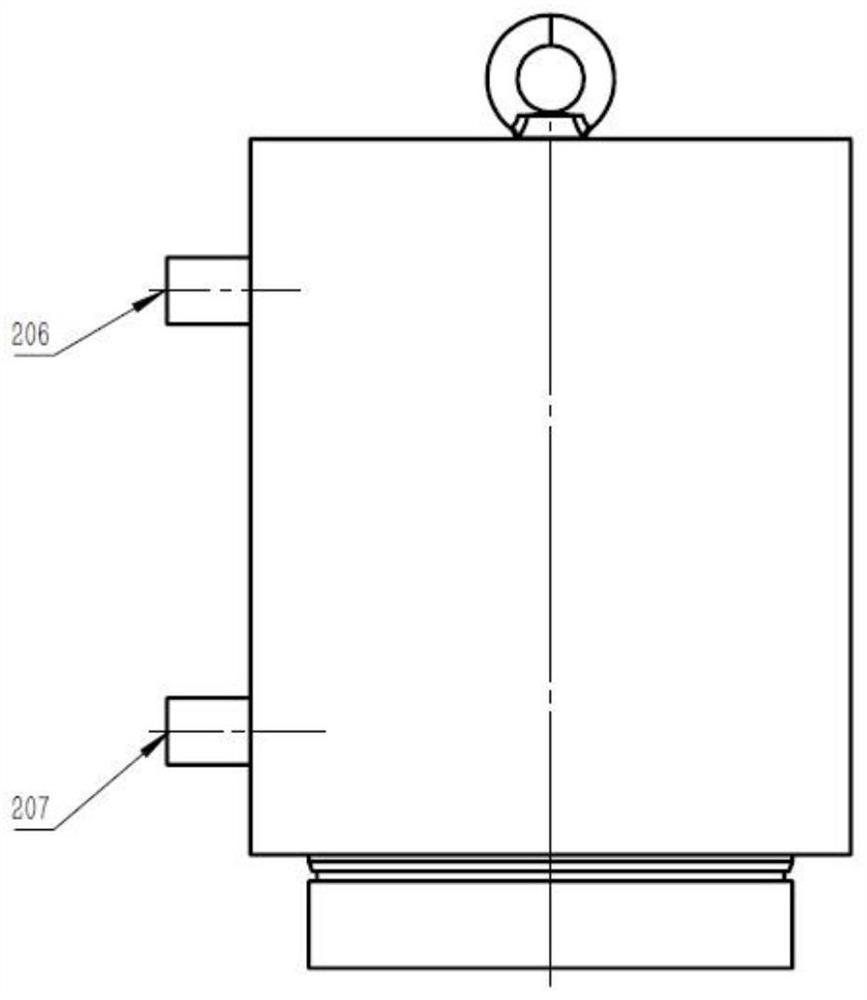

[0045] A kind of hydraulic key puller provided by the present invention, its structure is as follows figure 1 As shown, it consists of a hydraulic puller 1, a clamping block seat 2, a wedge-shaped clamping block 3 and a base 4. The hydraulic puller 1 is the core power part of the hydraulic key puller, which is a double-acting hollow hydraulic cylinder, such as figure 2 As shown, it is mainly composed of piston rod 201, outer cylinder body 202, hollow cylinder barrel 203, cylinder head 204, suspension ring 205, and some seals and guides. Such as Figure 2-Figure 6 As shown, the outer cylinder body 202 is provided with a first oil nozzle 206 and a second oil nozzle 207, and the cylinder head 204 is provided with a key outlet 208 and a threaded ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com