Diode production line

A production line and diode technology, applied in the field of diodes, can solve the problems of bending and breaking of diode feet, affecting the quality of diodes, and randomly stacking diodes on one side.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

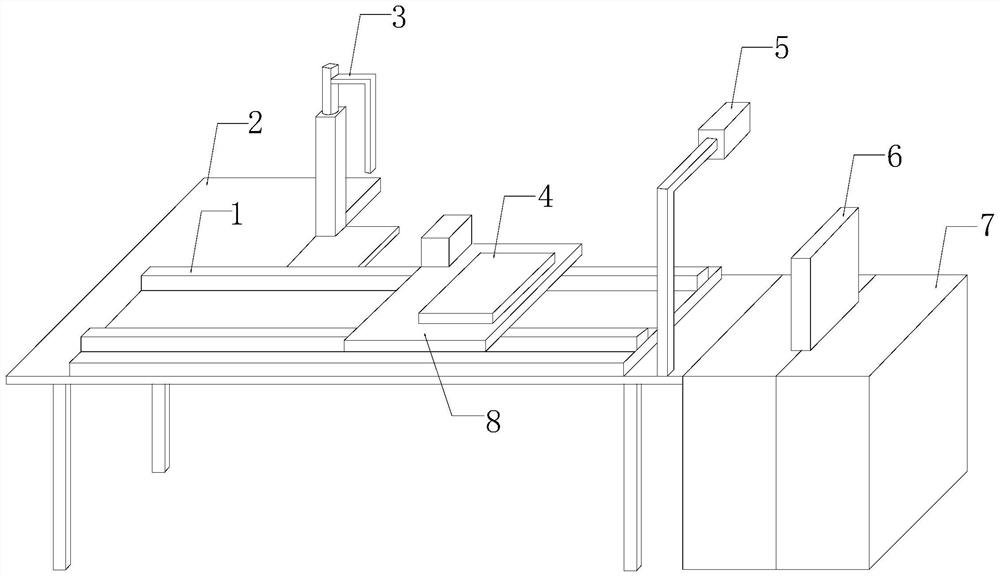

[0031] see figure 1 , the present invention provides a technical solution: a diode production line, the structure of which includes a slide rail 1, a workbench 2, a die bonder 3, a positioning device 4, a foot cutter 5, a detector 6, a main body 7, and a moving plate 8, The slide rail 1 is installed on the workbench 2, and the slide rail 1 is movably engaged with the moving plate 8. The end of the move plate 8 away from the slide rail 1 is fixedly connected with the positioning device 4. The workbench 2 and the main body 7 are connected as a whole, the main body 7 is provided with a detector 6 connected with it, and the workbench 2 is equipped with a die bonder 3 and a leg cutter 5 .

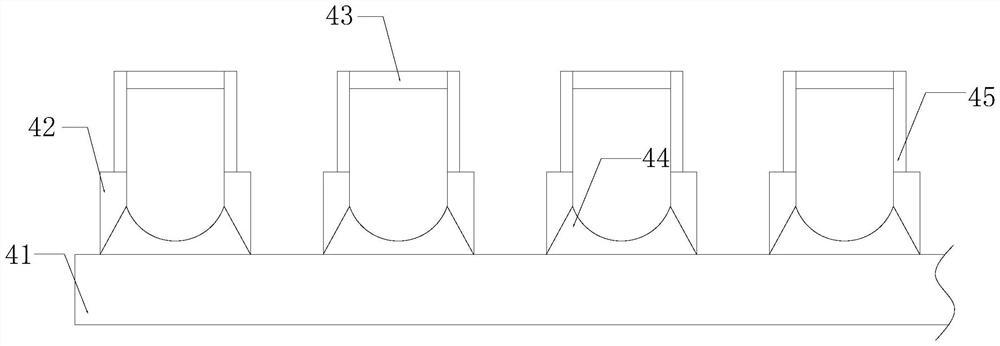

[0032] see figure 2 , the positioning device 4 includes a fixed seat 41, a cavity 42, a protective assembly 43, an adjustment clip 44, and a support rod 45, and four or more cavities 42 are installed on the fixed seat 41, four or more The cavities 42 are equally spaced and horizontally arran...

Embodiment 2

[0042] see figure 1 , the present invention provides a technical solution: a diode production line, the structure of which includes a slide rail 1, a workbench 2, a die bonder 3, a positioning device 4, a foot cutter 5, a detector 6, a main body 7, and a moving plate 8, The slide rail 1 is installed on the workbench 2, and the slide rail 1 is movably engaged with the moving plate 8. The end of the move plate 8 away from the slide rail 1 is fixedly connected with the positioning device 4. The workbench 2 and the main body 7 are connected as a whole, the main body 7 is provided with a detector 6 connected with it, and the workbench 2 is equipped with a die bonder 3 and a leg cutter 5 .

[0043] see figure 2 , the positioning device 4 includes a fixed seat 41, a cavity 42, a protective assembly 43, an adjustment clip 44, and a support rod 45, and four or more cavities 42 are installed on the fixed seat 41, four or more The cavities 42 are equally spaced and horizontally arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com