A kind of oil drill pipe with protective structure and its processing technology

A technology for protecting structure and processing technology, applied in drill pipe, drill pipe, earthwork drilling, etc., can solve the problems of inability to ensure wear resistance, enhanced pressure resistance of drilling oil cavity, etc., to ensure drilling transportation and not easy to slip , to avoid the effect of slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

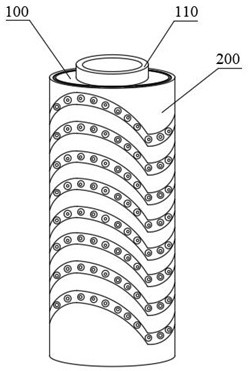

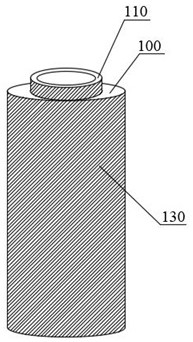

[0041] Such as Figure 1-7 As shown, the present embodiment provides a petroleum drill pipe with a protective structure, including a drill pipe body 100, the periphery of the drill pipe body 100 is detachably equipped with a wear-resistant casing 200, and the top of the drill pipe body 100 is provided with a protruding The oil outlet head 110 of the drill pipe body 100 is provided with a concave oil inlet head 120 at the bottom of the drill pipe body 100, and the oil outlet head 110 and the oil inlet head 120 of the drill pipe body 100 adjacent up and down are fixed and installed through the end protection structure 300, The end protection structure 300 is detachably connected to the oil outlet head 110 and the oil inlet head 120;

[0042] The end protection structure 300 includes a fastening ring 310, a fastener 320, and a sealing gasket 330. The fastening ring 310 is arranged on the periphery of the oil outlet head 110 and is higher than the oil outlet head 110. The lower su...

Embodiment 2

[0048] Such as Figure 5-6 , Figure 9 As shown, in this embodiment, the sections of the fastening ring 310 and the sealing gasket 330 are annular, and a plurality of fasteners 320 are distributed in an annular array on the periphery of the fastening ring 310, and the fasteners 320 include a connecting portion 323 And a section of mounting part 324, one end of the connecting part 323 is connected with the fastening ring 310, and the other end is connected with an arc-shaped mounting part 324, and the outer surface of the mounting part 324 is provided with serrated protrusions 325 for increasing friction; The mounting portion 324 is tightly pressed against the bottom inner periphery of the drill pipe body 100 . The fastener 320 including the connection part 323 and the installation part 324, in the process of fastening the oil outlet head 110 and the oil inlet head 120 adjacent up and down, the fastening ring 310 drives the installation part 324 to screw in, so that multiple i...

Embodiment 3

[0050] Such as Figure 4-6 As shown, a wall protection structure 400 is provided between the drilling oil cavity 140 and the inner wall of the drill pipe body 100. The wall protection structure 400 includes several wall cavities 410 arranged around them. A second compression spring 420 abuts against the inner walls on both sides of the wall cavity 410 . The setting of the wall protection structure 400, the second compression spring 420 set in the wall cavity 410 is a coil spring that bears the pressure, which relieves the impact force of the instantaneous large flow of oil on the oil drilling cavity 140 during the oil drilling and transportation process. , improve the pressure resistance of the oil drilling cavity 140 .

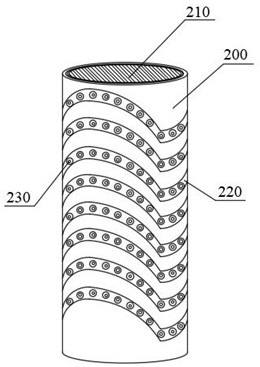

[0051] Such as Figure 1-2 As shown, the outer wall of the wear-resistant sleeve 200 is spirally provided with several circles of anti-slip cavities 220 sunken inwards, and the anti-slip cavities 220 are provided with a plurality of cutting protrusions 230 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com