An optimization method for wooden platform structure based on tinplate cladding

An optimization method and technology of wood structure, applied in the field of wood platform optimization, can solve the problems of increased risk factor, high tissue density, and heavy tin plate package bracket, so as to reduce waste of resources and reduce weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

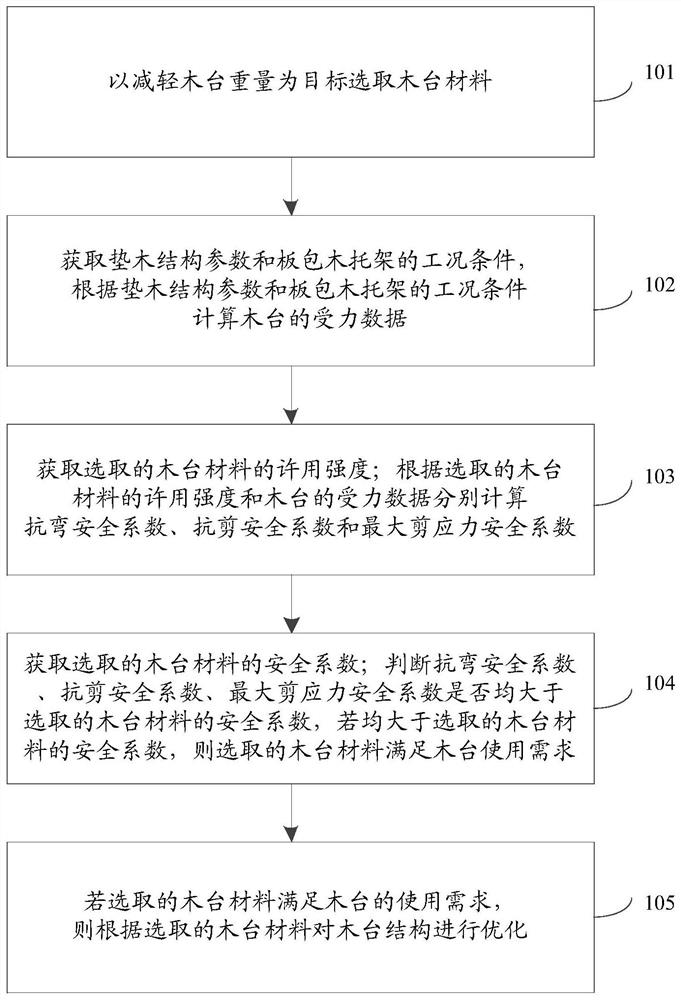

[0058] figure 1 It is a flow chart of the wooden table structure optimization method based on the tinplate board package in the embodiment of the present invention, such as figure 1 As shown, a wooden platform structure optimization method based on tinplate package, including:

[0059] Step 101: Select the material of the wooden platform with the goal of reducing the weight of the wooden platform.

[0060] Step 101 specifically includes: obtaining the wood parameters of each wooden table material to be selected; the wood parameters include wood density and wood tissue structure; comparing the wood parameters of each wooden table material to be selected with the goal of reducing the weight of the wooden table, and starting from the wooden table to be selected Among the materials, the wooden platform material with the smallest density and high similarity to the organizational structure of quincea was selected. The selected wooden table material is Douglas fir.

[0061] A) Accor...

Embodiment 2

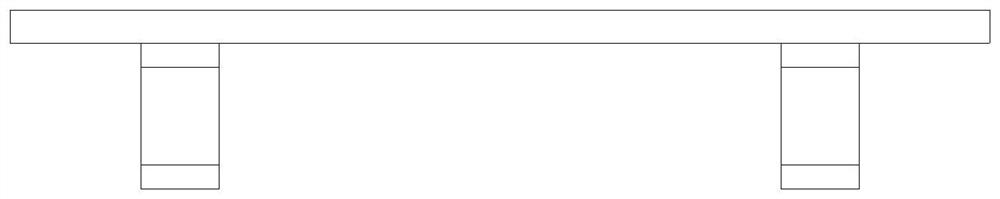

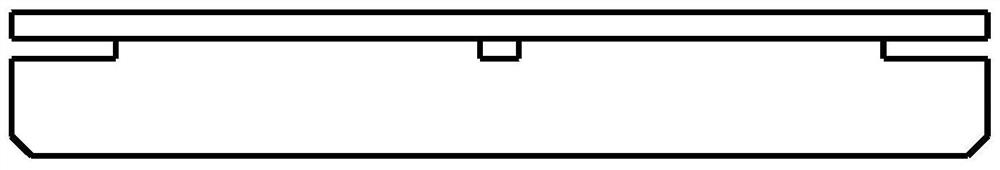

[0106] The size of the wooden bracket is L 2 Taking the product of ×b×h=750mm×60mm×75mm as an example, the method for optimizing the structure of wooden platform based on the tinplate cladding of the present invention will be described in detail. figure 2 It is a side view of the 700×700mm wooden bracket in the embodiment of the present invention, image 3 It is the front view of the 700×700mm wooden bracket in the embodiment of the present invention, such as Figure 2-3 As shown, the specific steps of the wooden platform structure optimization method based on the tinplate package are as follows:

[0107] A1) Timber parameters:

[0108] Hard wood

[0109] Hard miscellaneous wood is generally a general term for a type of wood with high density, hardness and strength. Its characteristics have the advantages of good adjustable force strength, strong economical practicability and so on. The disadvantage is that hard miscellaneous wood is not easy to process, and it is easy t...

Embodiment 3

[0129] The size of the wooden bracket is L 2 Taking the product of ×b×h=1230mm×70mm×75mm as an example, the method for optimizing the structure of the wooden platform of the tinplate cladding described in the present invention will be described in detail. Figure 4 It is a side view of the 1230×1230mm wooden bracket in the embodiment of the present invention, Figure 5 It is the front view of the 1230×1230mm wooden bracket in the embodiment of the present invention, such as Figure 4-5 As shown, the specific steps of the wooden platform structure optimization method based on the tinplate package are as follows:

[0130] A1) Timber parameters:

[0131] Hard miscellaneous wood is generally a general term for a type of wood with high density, hardness and strength. It is often used as a support frame inside furniture, which is economical and practical. However, hard miscellaneous wood is not easy to process, and it is easy to crack if the fumigation is unreasonable. Commonly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com