Hot rolling manufacturing process for deformed steel bars

A manufacturing process and rebar technology, which is applied in the field of rebar hot rolling manufacturing process, can solve the problems that the rebar cannot be corrected, the rebar is prone to bending, and the forming is not complete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

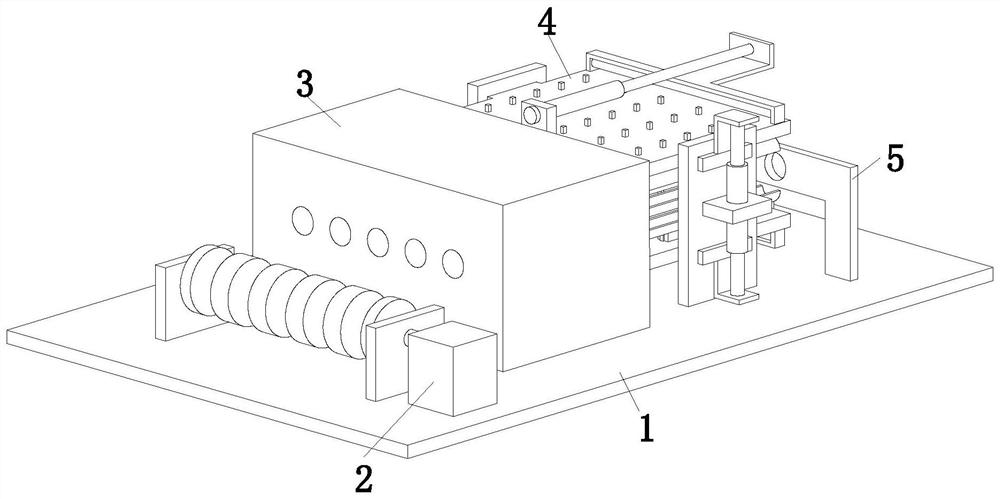

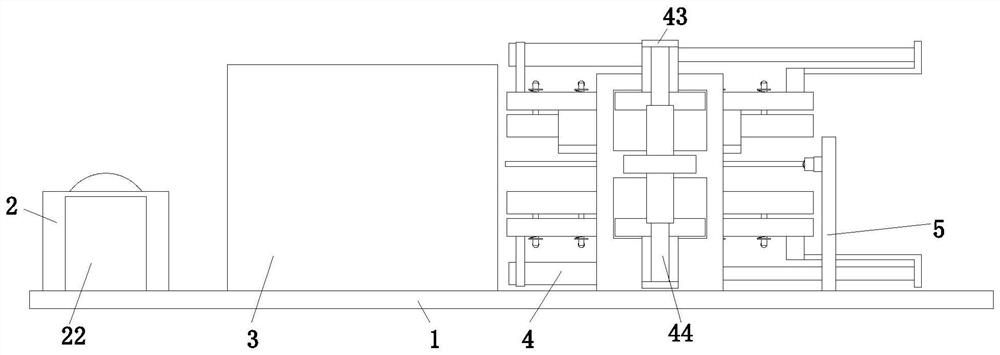

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

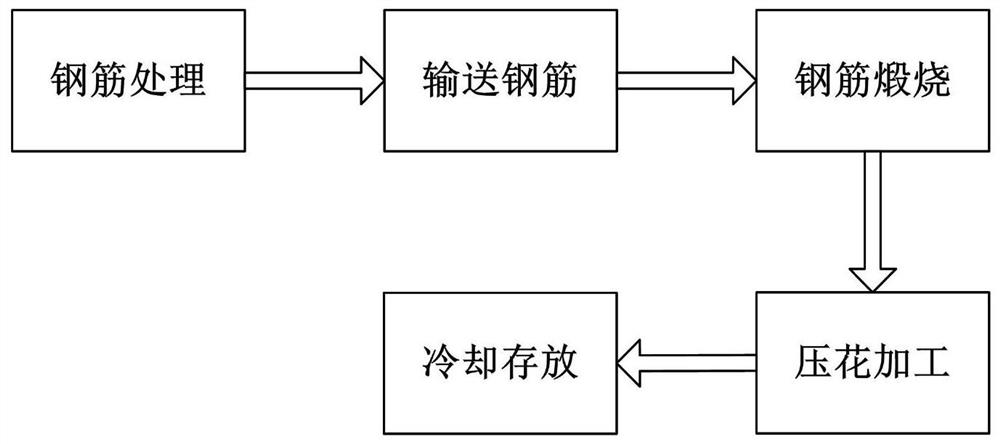

[0035] like Figure 1 to Figure 7 As shown, in order to achieve the above object, the present invention adopts the following technical solutions, a threaded steel hot-rolled manufacturing process, which uses a threaded steel hot-rolled manufacturing equipment, the screwed steel hot-rolled manufacturing equipment includes a main board 1, a conveying device 2 , heating furnace 3, molding device 4 and molding device 5, when adopting screw steel hot rolling manufacturing equipment to carry out compression molding to screw steel, specific method is as follows:

[0036] S1. Steel bar treatment: manually select the steel bar to be processed, and remove the rust on the surface of the steel bar;

[0037] S2. Conveying steel bars: placing a plurality of stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com