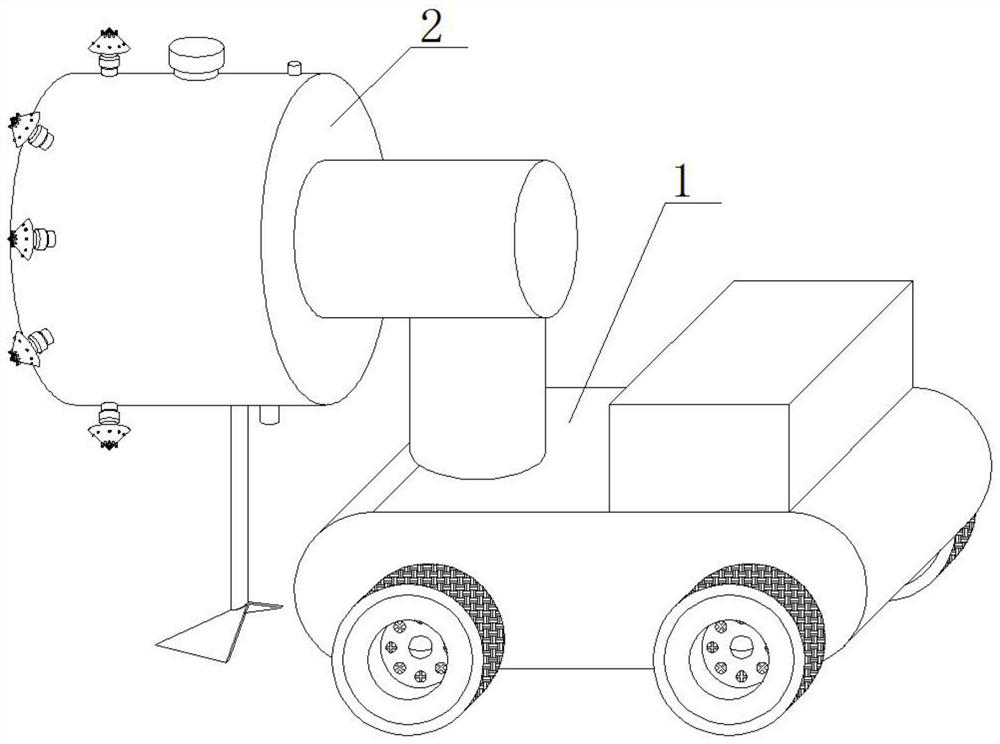

Pipeline cleaning and impurity removing device suitable for various pipeline diameters

A technology of pipe diameter and cleaning device, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, filtration and separation, etc., can solve the problems of fluid flow obstruction, cleaning difficulty, pipe scale cleaning difficulty, etc., and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

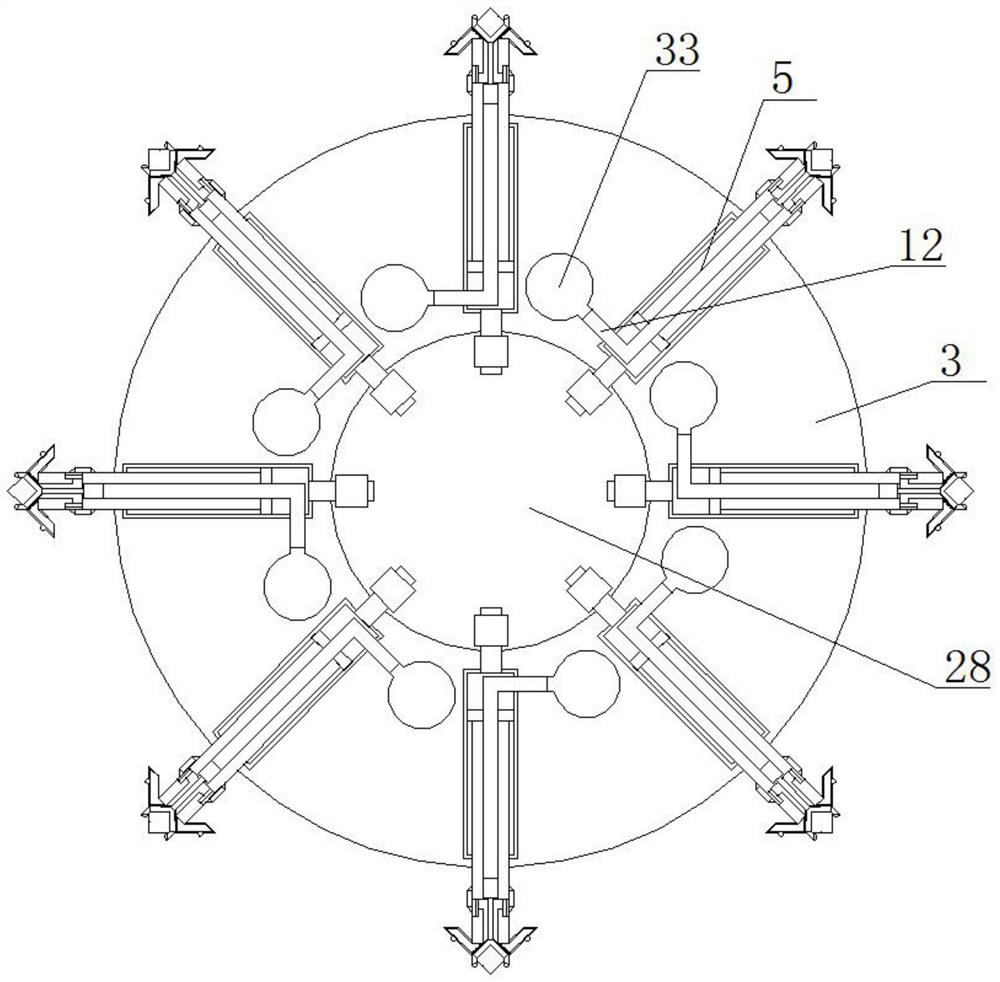

[0032] As a preferred embodiment of the present invention, the convex oil storage tank 28 is filled with hydraulic oil.

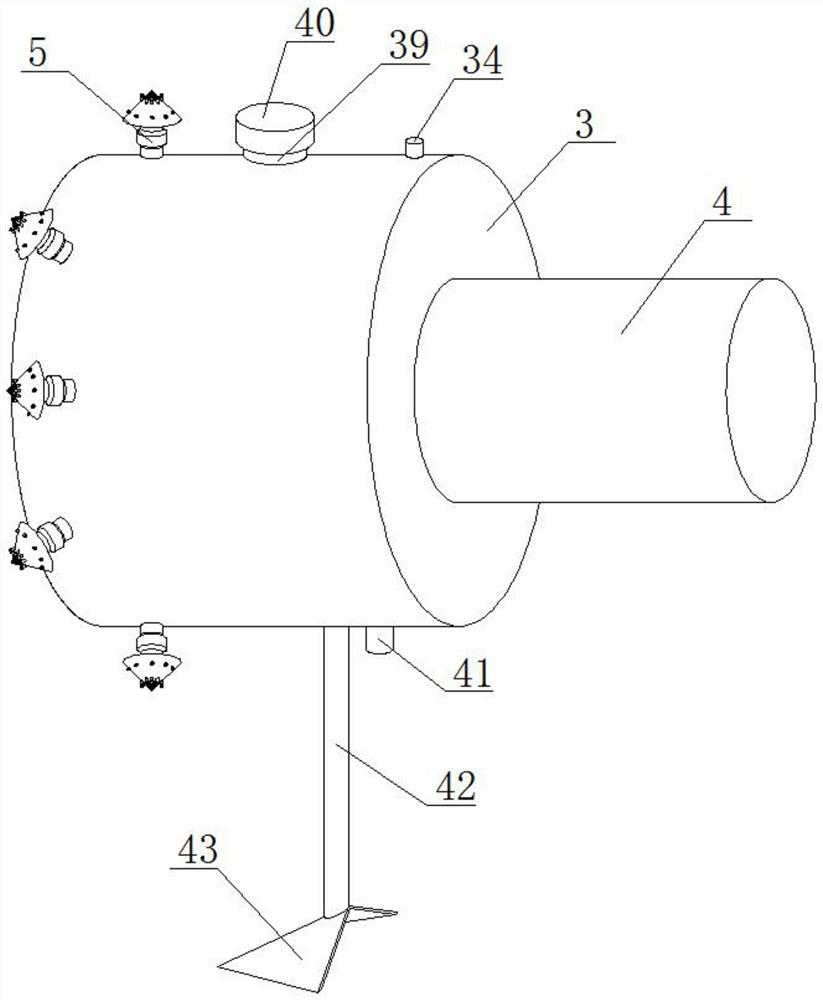

[0033] As a preferred embodiment of the present invention, several pipe scale crushing mechanisms 5 on the self-adaptive cleaning head 3 can stretch out and stick to the pipe scale surface on the inner wall of the pipeline, and carry out the pipe scale with the same pressure. Broken and cleared, when in use, pair the remote control car 1 with a suitable remote control device, input the diameter of the pipe to be cleaned, connect the water inlet pipe 34 to a water source with a certain water pressure through the pipe, clean out the bottom of the pipe and place the remote control car 1, the distance sensor 41 monitors the distance between the scale cleaning device 2 and the bottom of the pipeline, and the processor calculates the relative distance between the scale cleaning device 2 and the inner wall of the pipeline according to the diameter of the pipeline a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com