Construction waste cyclic crushing device

A technology for cyclic crushing and construction waste, which is used in solid separation, separation of solids from solids by air flow, and grain processing. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

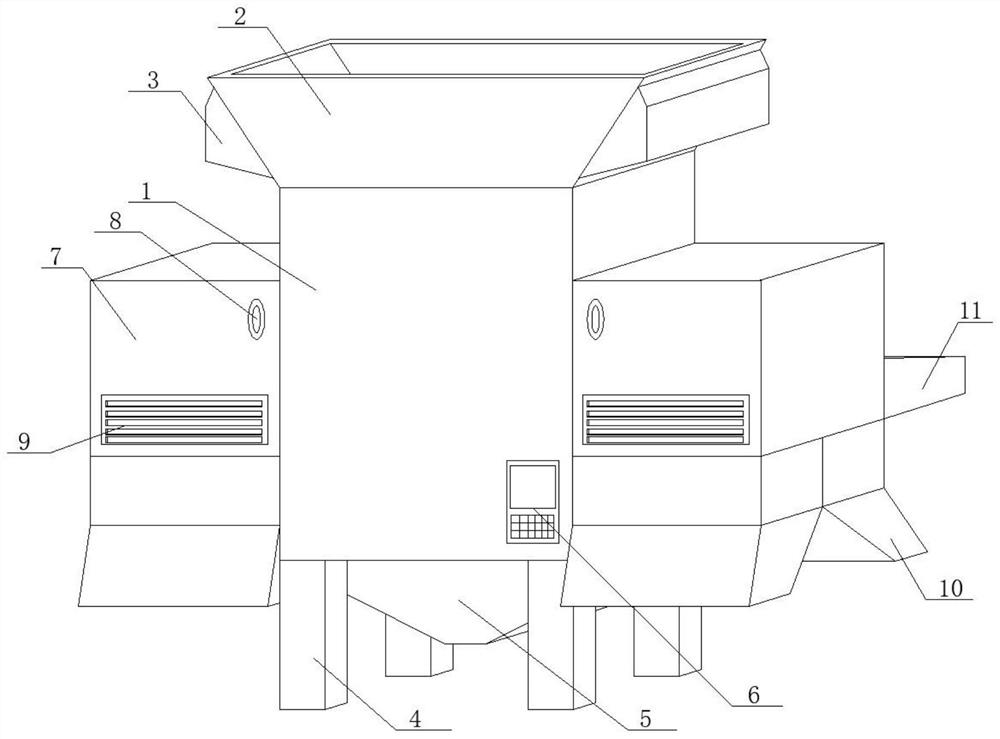

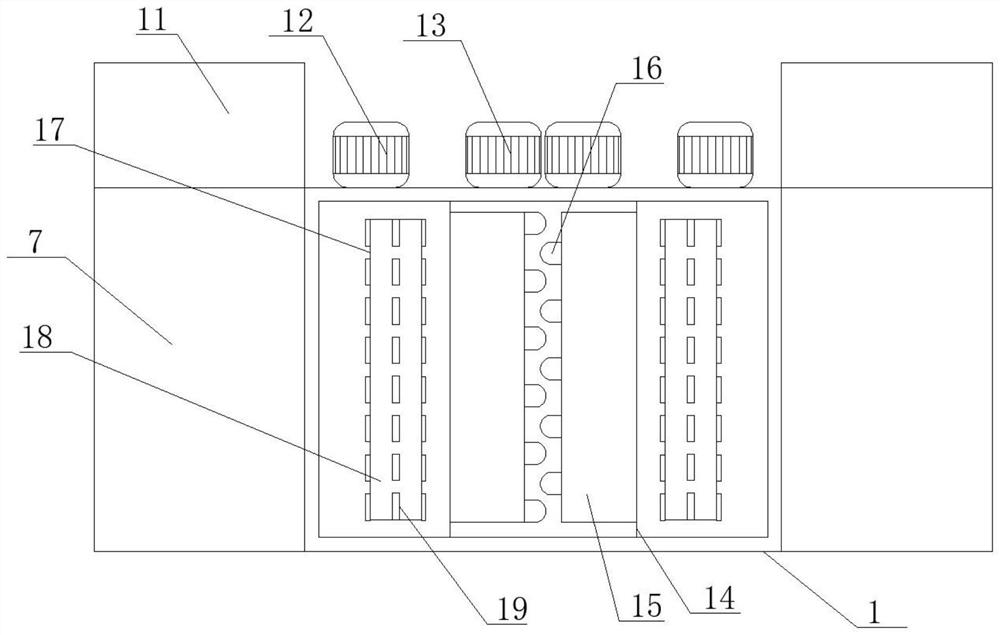

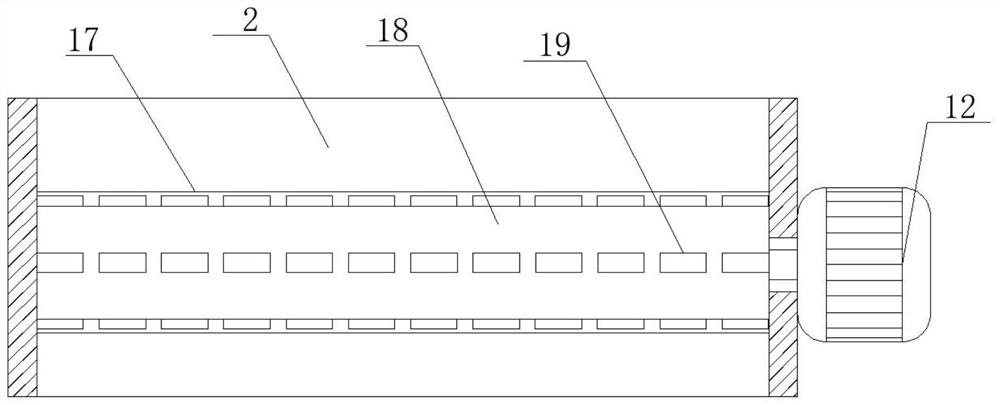

[0027] see Figure 1-3 , in the embodiment of the present invention, a construction waste circulation crushing device comprises a treatment main box 1, the top surface of the treatment main box 1 is horizontally welded with a blanking hopper 2, and the two sides of the blanking hopper 2 are symmetrically welded with an outer cover body 3, and the processing The bottom surface of the main box 1 is welded with a support pole 4 vertically downward, the top surface of the blanking hopper 2 is provided with an opening, and the inside of the blanking hopper 2 is kept connected with the inside of the feeding port 14, and the outer cover body 3 is buckled respectively. The shape is fixedly arranged at the opening end position of the extension groove 17, and the inside of the outer cover body 3 is kept in communication with the inside of the extension groove 17. The number of support poles 4 is four, and the four support poles 4 are connected to each other. Arranged in parallel, the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com