High temperature mat for a polltion control device

A technology of pollution control and pollution control components, which is applied in the field of installation materials and high-temperature gaskets, and can solve the problems of high economic cost and low fiber density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and C1-C6

[0062] Table 2

[0063] * Kaowool available from Thermal Ceramics TM HA

[0064] ** Saffil purchased from ICI TM 0BM

[0065] *** Fiberfrax from Unifrax TM 7000M

[0066] The data in Table 1 shows that the liner of the present invention exhibits less shrinkage and excellent RCFT test pressure retention.

[0067] table 3

[0068] The data in Table 3 show that the gaskets of the present invention resist cold abrasion better than gaskets made from amorphous annealed fibers alone. Although Example C5 had comparable abrasion resistance, it required an unsuitable lamination step prior to end use.

Embodiment 4-6

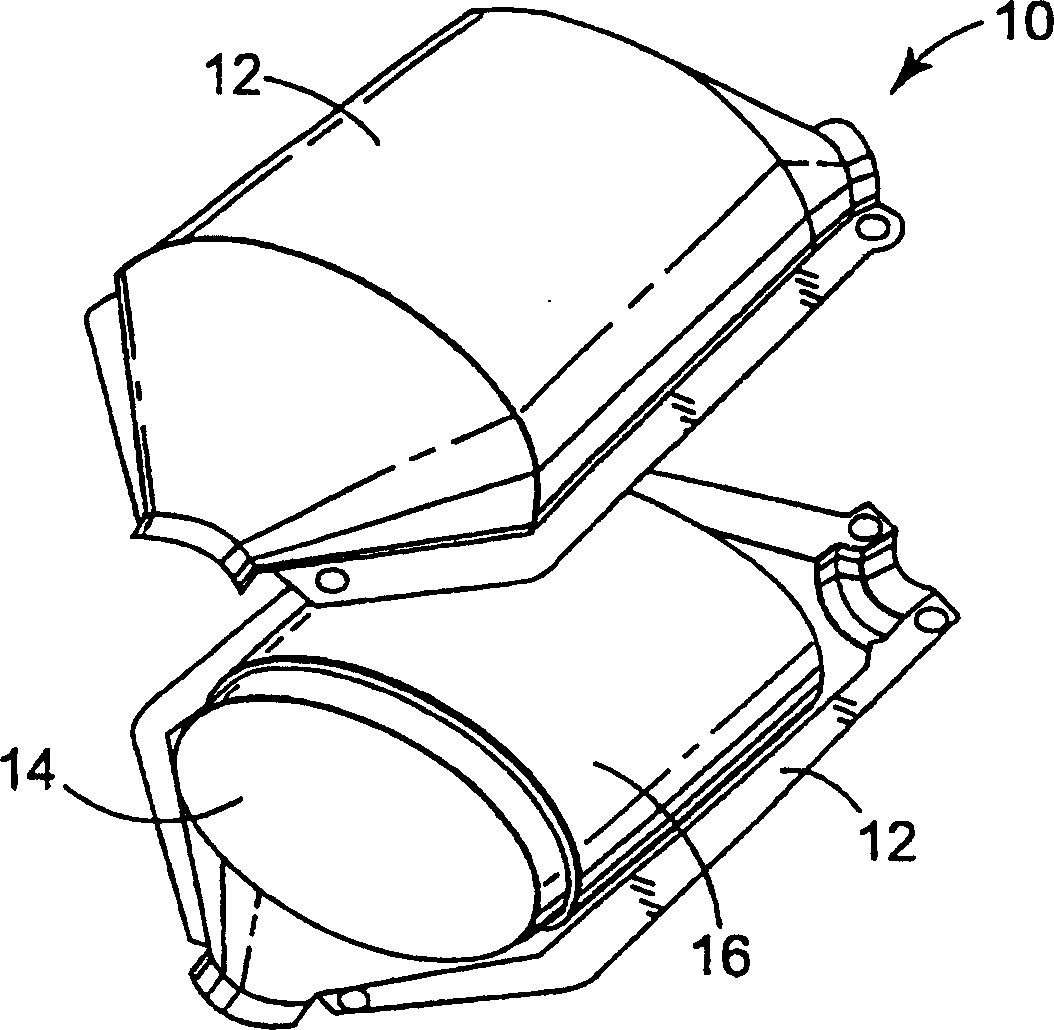

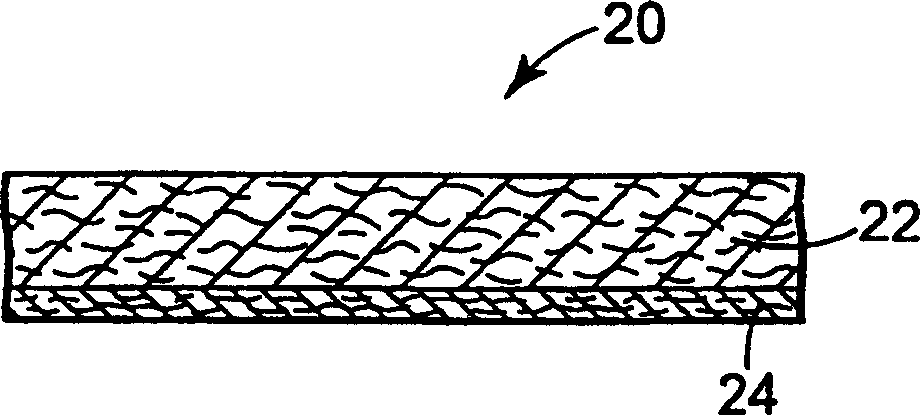

[0070] The liners of Examples 1-3 and intumescent material liners such as Interam® available from 3M Company TM The Type 100 pads were combined to produce a two layer pad with an intumescent layer and a non-intumescent layer in each layer. These two layers of gaskets are installed between the monolith and the metal casing, with the layer of non-intumescent material against the monolith and the layer of intumescent material against the casing, to make a catalytic converter. Alternatively, the intumescent layer can also be installed against the whole piece.

[0071] In Example 7, an intumescent material was combined with the ceramic-based polycrystalline fiber and the annealed fiber of Example 1. Specifically, unexpanded vermiculite was added to the fiber of Example 1, and its addition accounted for 30% by weight of the material. The density of the made pad is 0.1-0.7 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com