Negative electrode active material for rechargeable battery, method for producing same, and rechargeable battery

A negative electrode active material and secondary battery technology, applied in active material electrodes, battery electrodes, negative electrodes, etc., can solve problems such as capacity degradation, fragmentation, and lithium ion reduction, and achieve the effect of increasing specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

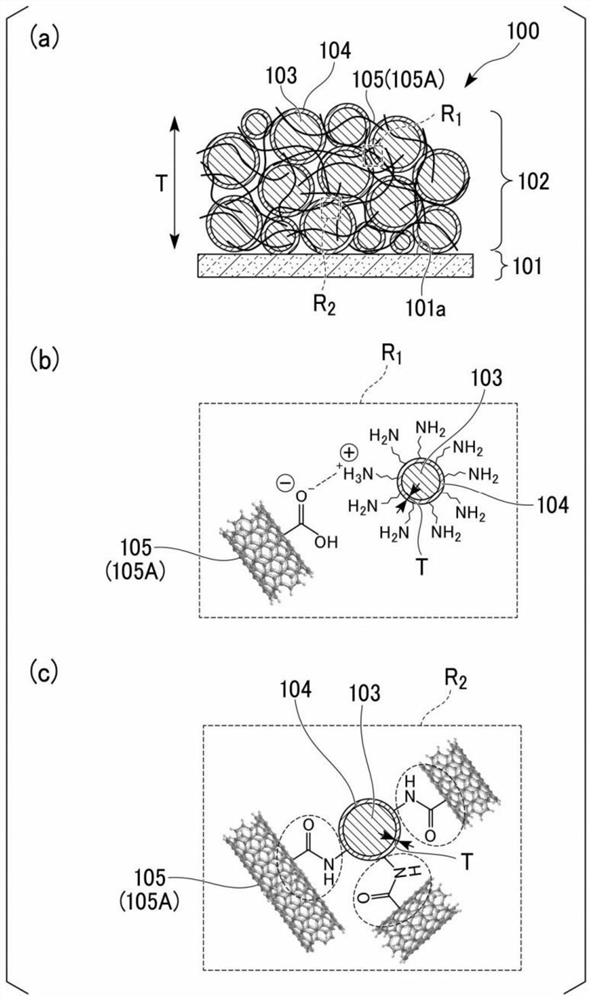

[0071]The negative electrode having a negative electrode active material having a secondary battery as in Example 1 was fabricated by the following steps (steps 1 to 5).Figure 4 (a) ~ (d) is a diagram for a schematic description for each step.

[0072][Process 1]

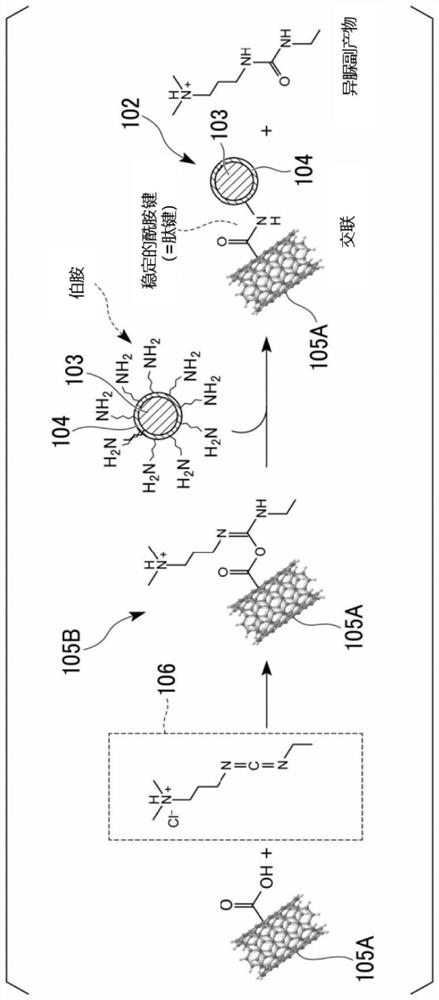

[0073]First of all, ifFigure 4 (a), the multi-layer carbon nanotube (MWCNT) 105A is stored at room temperature in the container V2Water in (H2O) Mixing, allowing 9% by weight to prepare a mixture of multi-layer carbon nanotubes 105a3Carboxyl groups (-COOH) are formed on the surface of the multilayer carbon nanotubes 105a. As the multilayer carbon nanotube 105a, a length of 500 to 700 nm is used, a diameter of 15 to 20 nm, and a plurality of layers of carbon nanotubes having a layer of 15-18 are used.

[0074][Process 2]

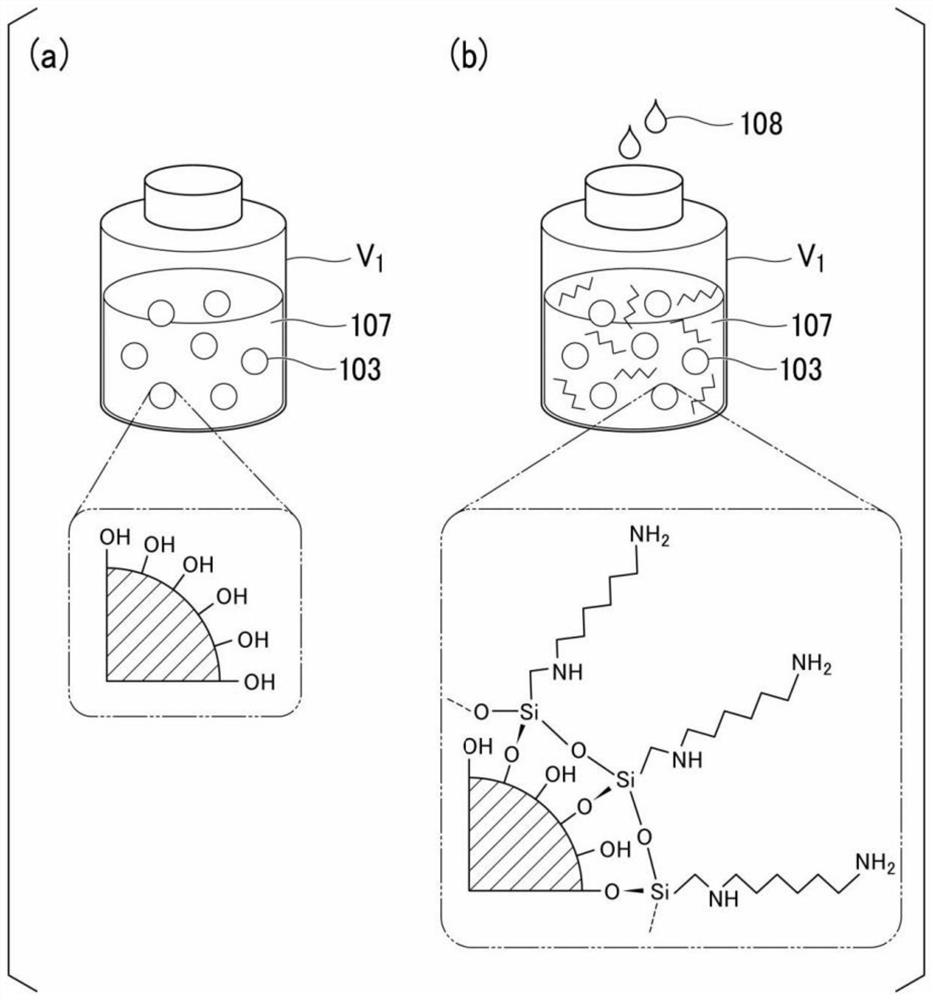

[0075]Further, at room temperature, the weight ratio of 33% is mixed with a silicon-containing silicon complex 103 containing graphite than the silicon complex 103 containing graphite than the silicon complex 103, w...

Embodiment 2

[0082]As the negative electrode of the secondary battery, the negative electrode active material for the second embodiment is made only by changing the steps of the step 1 of the first embodiment. That is, in the step 1, a plurality of layers of carbon nanotubes and 1.5 mg of powdery EDC are mixed with water stored in the container, and the mixed liquid L is prepared.7. The steps of other steps were the same as in Example 1.

Embodiment 3

[0084]As the negative electrode of the negative electrode active material for the secondary battery, the negative electrode having the secondary battery is made in the same steps as in Example 1. However, the mixed organosilane is 200 μL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com