Chemical device risk assessment method based on OWA operator empowerment

A technology of risk assessment and chemical engineering, applied in the direction of calculation, manufacturing calculation systems, instruments, etc., can solve the problems of non-chemical production process safety assessment methods, etc., to achieve the effect of ensuring scientific rationality, simple calculation process, and reducing negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

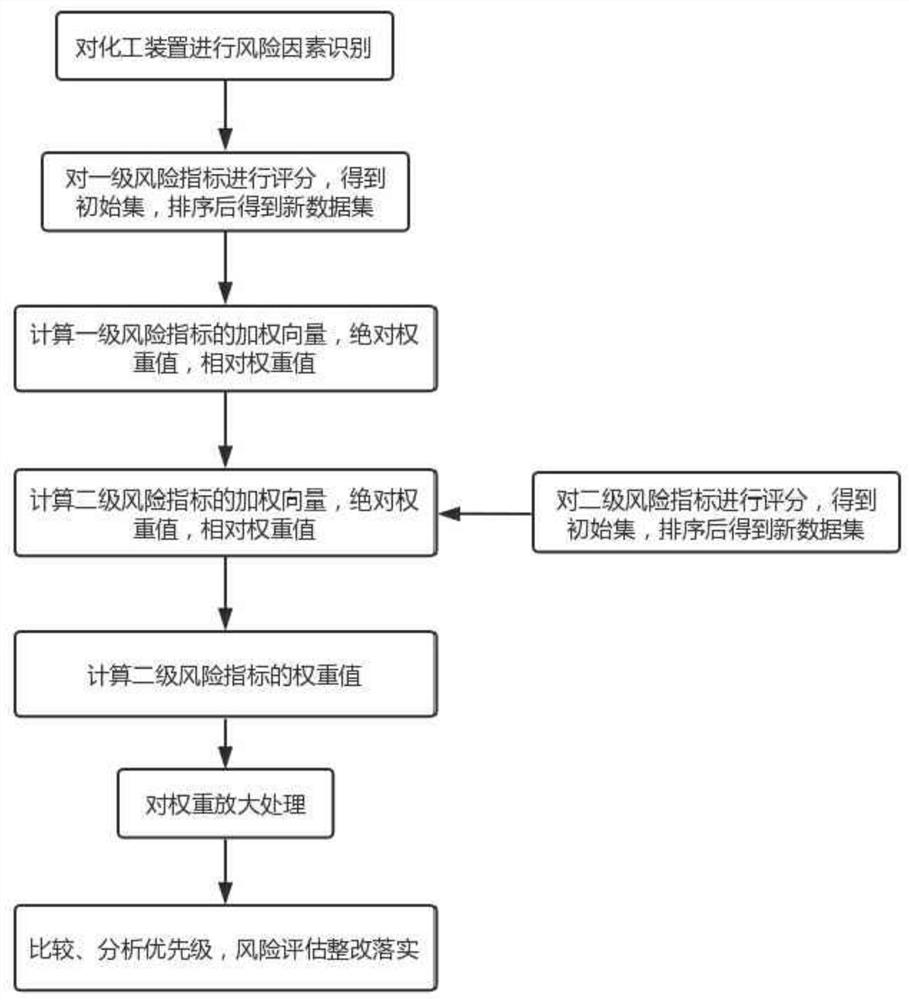

[0044] Such as figure 1 As shown, a chemical plant risk assessment method based on OWA operator weighting, including: according to the analysis of chemical risk factors, obtain the first-level risk factor index and the second-level risk factor index of the process plant evaluation risk factor;

[0045] Evaluate the degree of influence of the first-level risk factor indicators, and correspondingly give the first-level decision-making data set of each first-level risk factor indicator;

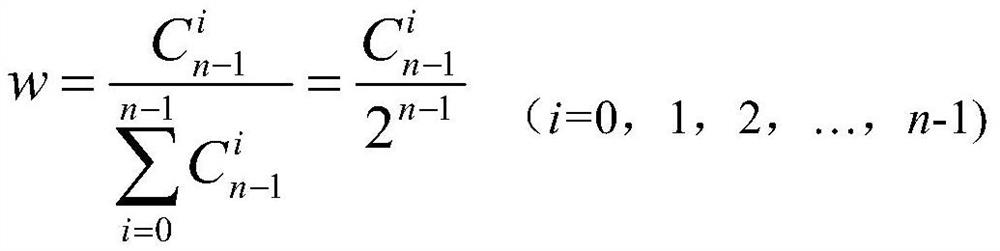

[0046] Sort and number each first-level decision-making data set, and calculate each weighted vector in each first-level decision-making data set;

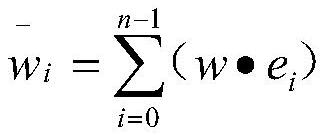

[0047] Weight the first-level decision-making data set through the weighting vector to obtain the absolute weight value of each first-level risk factor indicator; normalize the absolute weight value of each first-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com