Ultrasonic testing test block, its preparation method and application

A technology of ultrasonic testing and test blocks, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, which can solve problems such as difficult to ensure positional accuracy, difficult to ensure dimensional accuracy, uneven shape, etc., and achieve improved accuracy , good calibration work, convenient size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

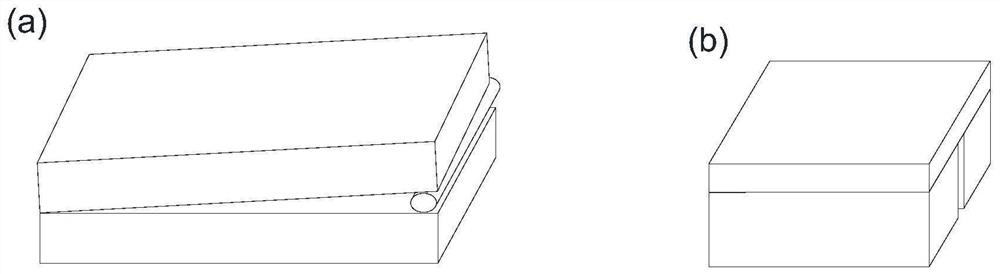

[0029] like figure 2 As shown, an embodiment of the present invention provides a method for preparing an ultrasonic testing test block, comprising the following steps:

[0030] S1, making cracks

[0031] The first base material and the second base material are placed on top of each other, and a cushion member is placed between the ends of the two contact surfaces of the first base material and the second base material, so as to form a joint from the first base material and the second base material. A gap of increasing width from the first end to the opposite second end; the first and second ends of the first and second substrates are then secured.

[0032] Specifically, superimposing the first substrate and the second substrate may be to place the first substrate above the second substrate to form a structure of two layers of substrates.

[0033] In some embodiments, both the first substrate and the second substrate are titanium alloy slabs, such as TC4. The specific size ...

Embodiment 1

[0054] The present embodiment provides a method for preparing an ultrasonic testing test block, which includes:

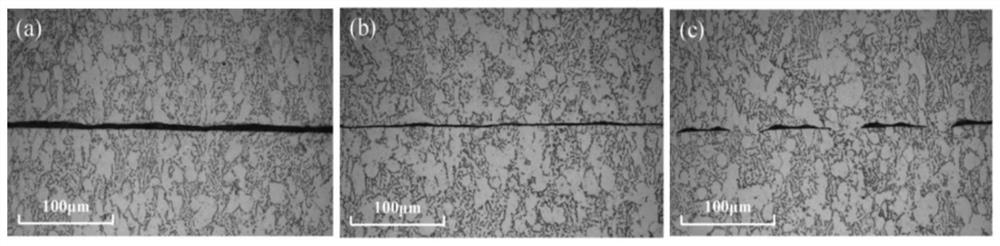

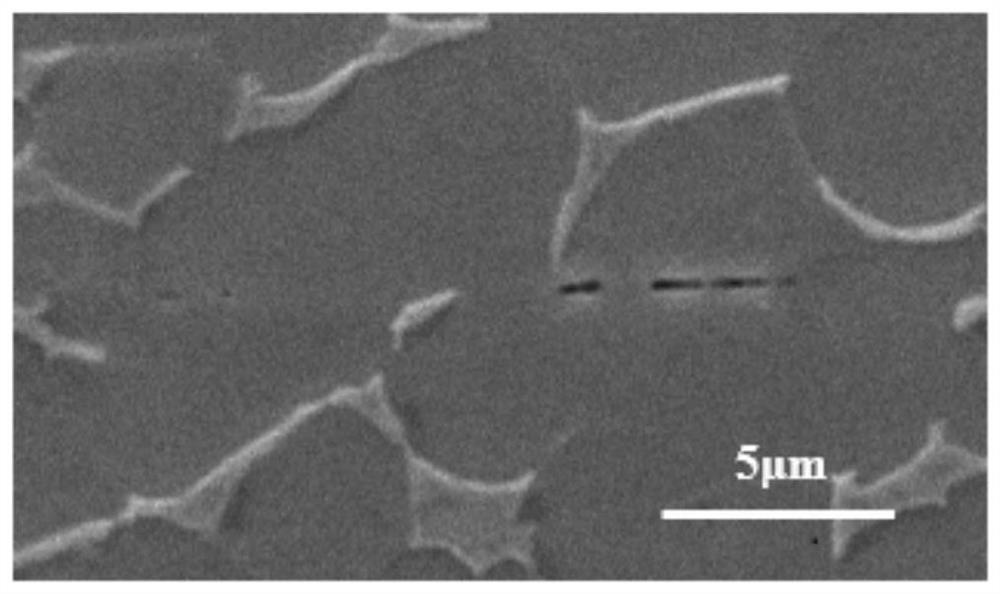

[0055] (1) Making the gap: first grind the surface of the 20×10mm plane of the two TC4 titanium alloy blocks (20×10×5mm) until there are no obvious scratches, and connect the grinding surfaces, such as figure 2 As shown in (a), the two TC4 blocks are butted, and the right end is filled with molybdenum wire at the end of the butt interface (the cylinder represents a molybdenum wire with a diameter of 180 μm), and then the bow clamp is fixed, and the two ends of the butt block plate (the part of the seam) are fixed. The narrowest end and the widest end) are retained by TIG welding to obtain a continuously changing gap.

[0056] (2) Preparation before diffusion welding: Clean the surface to be welded of the cover plate and the non-defective positions of the two sandwich block plates in (1), first grind the surface with sandpaper step by step, and use polishing liquid...

Embodiment 2

[0060] The present embodiment provides a method for preparing an ultrasonic testing test block, which includes:

[0061] (1) Making the gap: first grind the surface of the 20×10mm plane of the two TC4 titanium alloy blocks (20×10×5mm) until there are no obvious scratches, and connect the grinding surfaces, such as figure 2 As shown in the middle (a), the two TC4 blocks are butted, and the right end is filled with molybdenum wire at the end of the butt interface (the cylinder represents a molybdenum wire with a diameter of 100 μm), and then the bow clamp is fixed, and the two ends of the butt block plate (the part of the seam) is fixed. The narrowest end and the widest end) are retained by TIG welding to obtain a continuously changing gap.

[0062] (2) Preparation before diffusion welding: Clean the surface to be welded of the cover plate and the non-defective positions of the two sandwich block plates in (1), first grind the surface with sandpaper step by step, and use polish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com