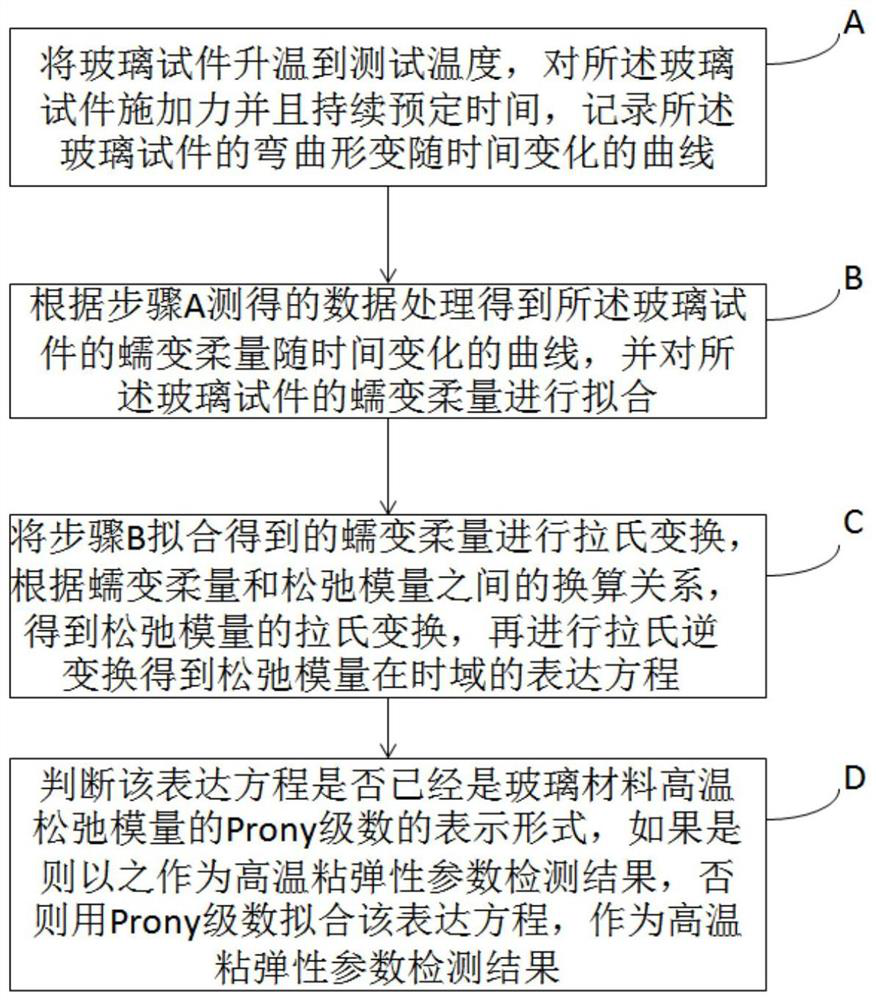

Method for detecting high-temperature viscoelastic parameters of glass material

A technology for parameter detection and glass materials, applied in the direction of analyzing materials, using stable bending force to test the strength of materials, measuring devices, etc., can solve the problems that the test pieces are easy to break, cannot be reached, and glass viscoelastic parameters cannot be obtained. The effect of achieving effective and reliable viscoelastic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0068]A specific example of determining the high temperature relaxation modulus of the glass material is determined below.

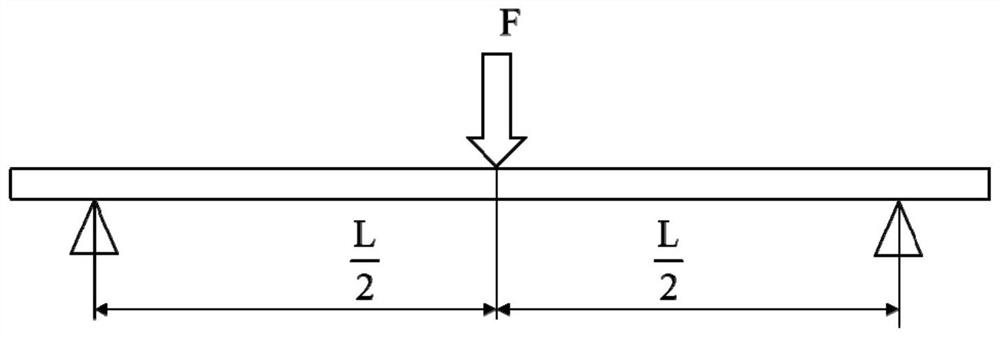

[0069]Step 1: Three-point bending experiments for the glass material measuring the high temperature creep strength of the glass material using a thermomechanical analyzer (TMA).

[0070]Such asfigure 2 As shown, a three-point bending experiment is used, and the glass sample is warmed to the test temperature. In this example, the temperature is 730 ° C, and the glass sample is applied to the glass sample, and the experiment is started to last for 30 min until the deformation is too large. Record the curve of the sample curved shape varies.

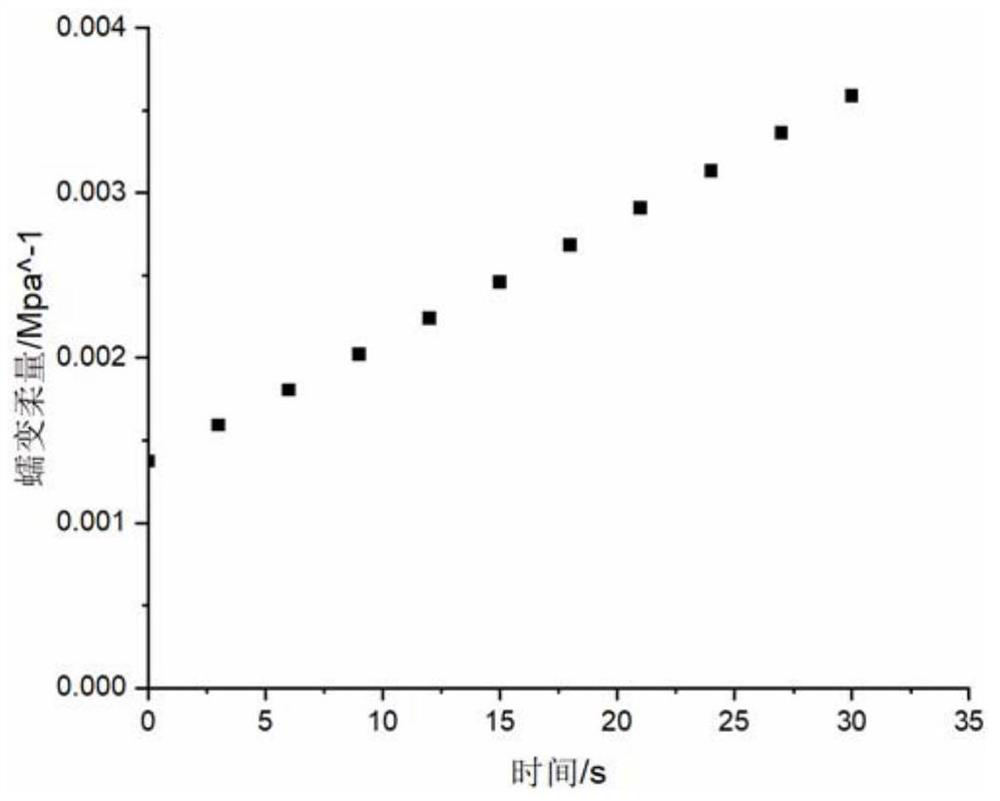

[0071]Step 2: High temperature creep pushing of the glass material.

[0072]The resulting data is obtained according to the measured data processing, and the glass creep is changed with time, such asimage 3 Indicated. It is found that this curve is approximately a straight line, so it can be regarded as a Maxwell's constitutive model. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com