Ceramic bearing

A technology of ceramic bearings and ceramic materials, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of short service life, unsatisfactory effect and high manufacturing cost of metal oil bearings, so as not to loosen and fall off , Overcoming the effect of easy breakage and not easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

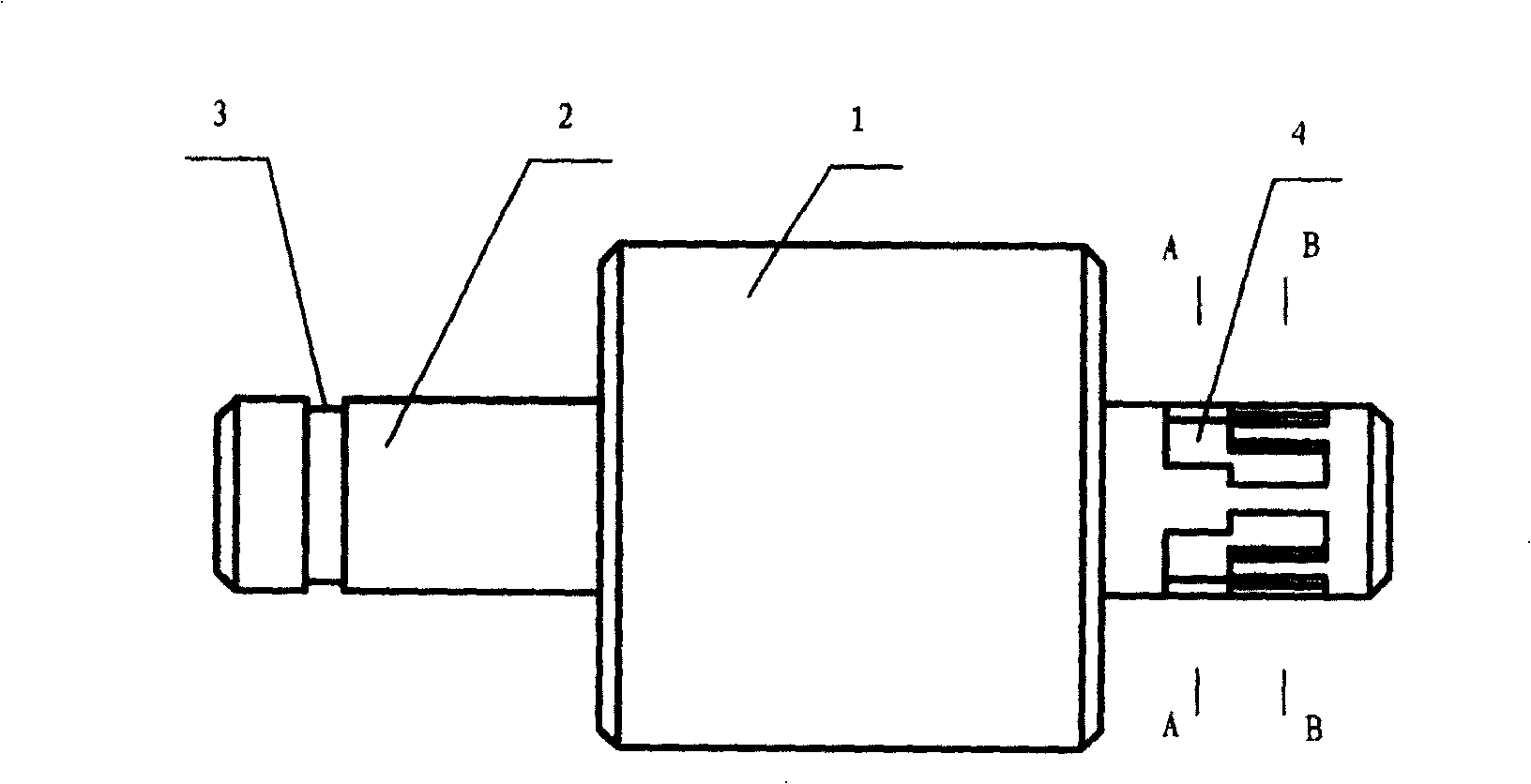

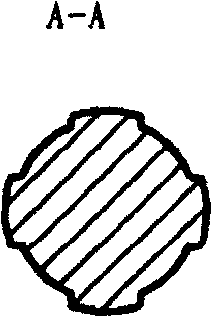

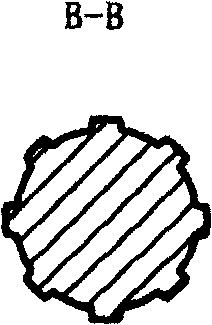

[0009] like figure 1 The shown ceramic bearing includes a shaft sleeve 1 and a shaft rod 2. The shaft sleeve 1 and the shaft rod 2 adopt a clearance fit. There are four grooves in one row, eight grooves in one row, and two rows of grooves are arranged in a staggered manner.

[0010] Both the shaft sleeve and the shaft rod are made of ceramic material, which is mainly composed of zirconia and has the characteristics of high hardness and wear resistance, so the invention has a long service life. There are two rows of vertical grooves on the tail of the shaft. The tail of the shaft is closely matched with the fan base. The shaft sleeve and the shaft adopt a clearance fit structure. The invention has the advantages of not being easy to vibrate and having low noise.

[0011] Figure 4 is another embodiment of the present invention. There is a row of vertical grooves at the end of the shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com