Automatic filling valve for vertical liquefied gas cylinder

A liquefied gas, vertical technology, which is applied to the container filling method, the equipment for loading pressure vessels, the installation device of the container structure, etc. The effect of filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

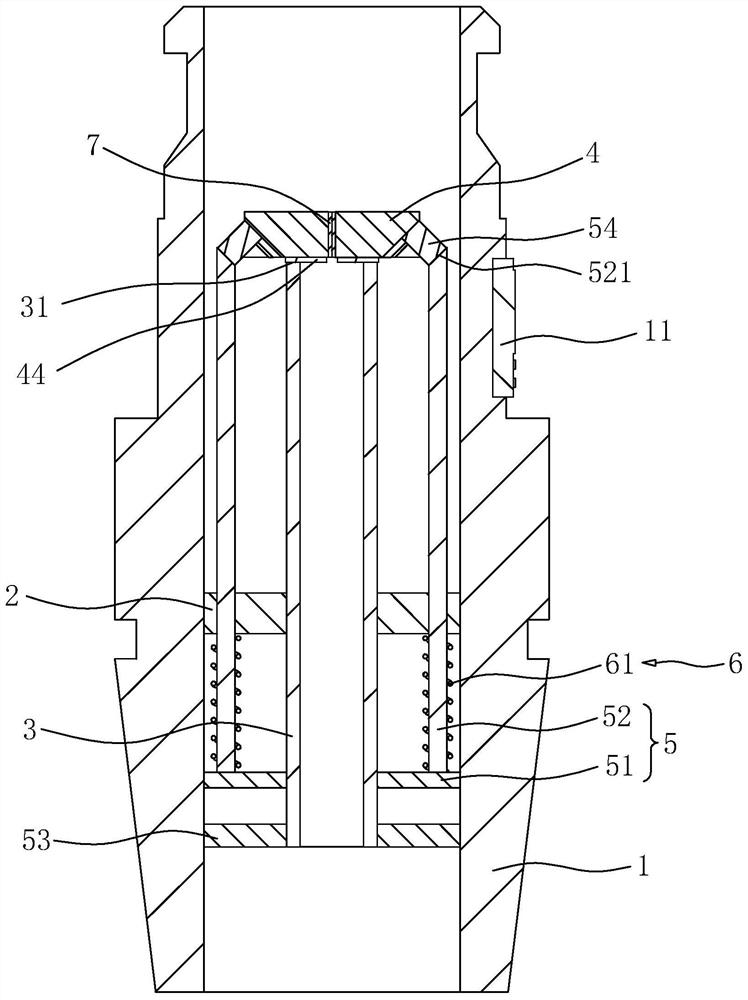

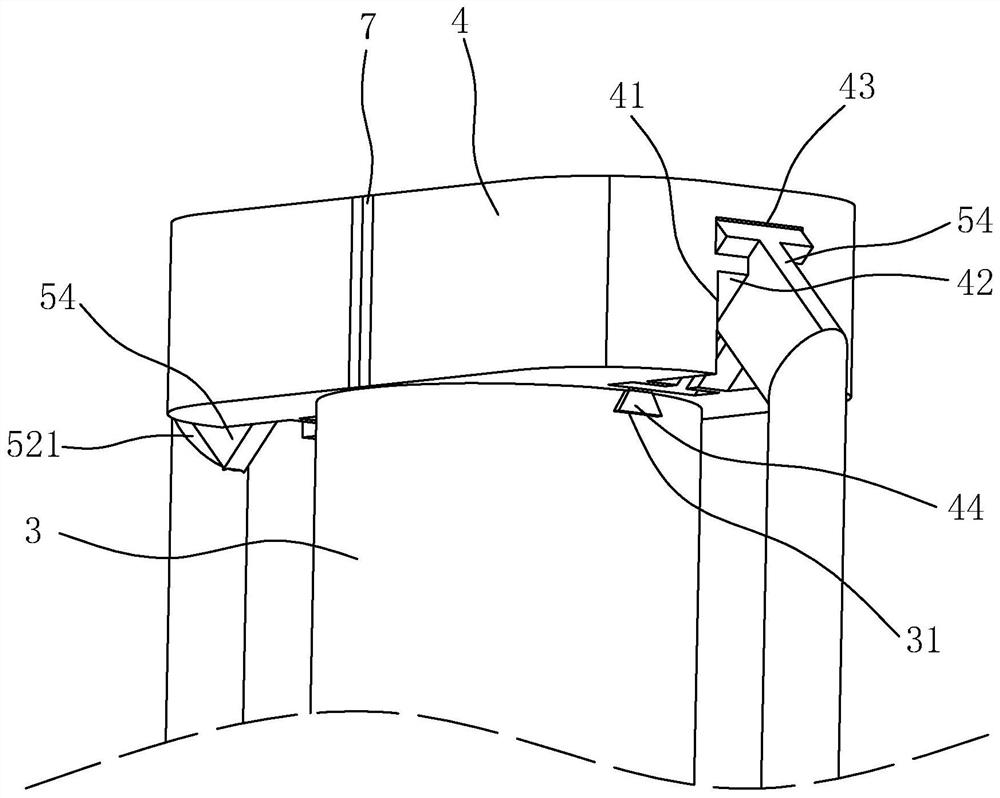

[0034] The following is attached Figure 1-3 The application is described in further detail.

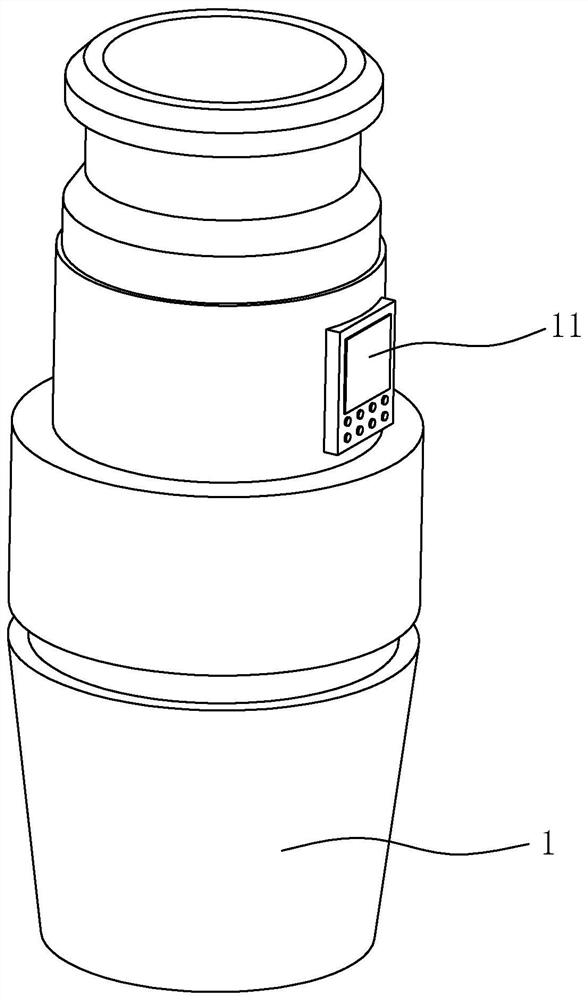

[0035] The embodiment of the present application discloses an automatic filling valve for a vertical liquefied gas cylinder. refer to figure 1 , The automatic filling valve for vertical liquefied gas cylinders includes a valve body 1, the valve body 1 is vertically arranged and the inside is hollow. The bottom end of the valve body 1 is set in a conical shape, and is used for communicating with the liquefied gas cylinder. The valve body 1 is used to open or close the mouth of the liquefied gas cylinder.

[0036] refer to figure 1 , the outside of the valve body 1 is installed with an electronic chip 11 for recording the information of the liquefied gas cylinder. After the inflatable gun is installed on the valve body 1, the inflatable gun can obtain the information of the liquefied gas cylinder by scanning the electronic chip 11, so as to judge Whether the liquefied gas cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com