Large diameter nail head lead wire filling equipment

A nail head lead and filling equipment technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of easy pollution of the end face of the nail head, the decline of the electrical properties of the diode, and the filling and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

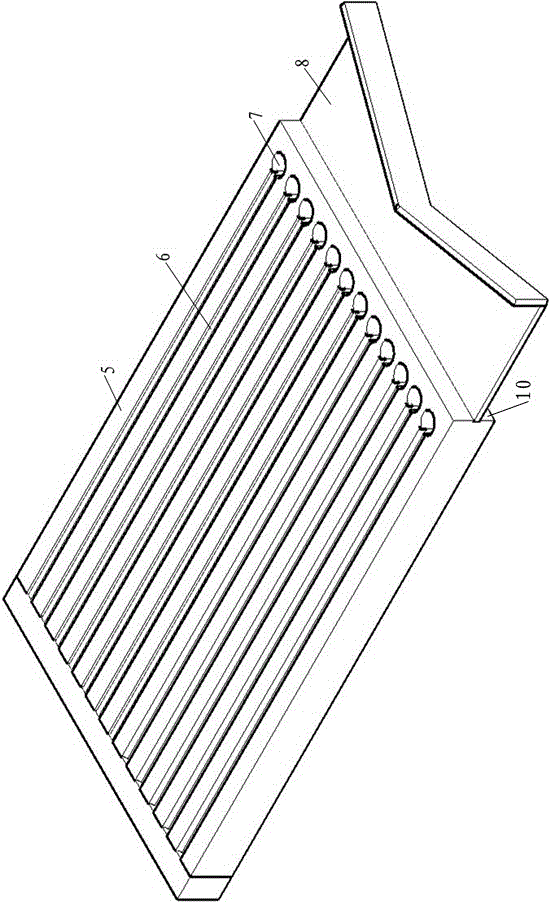

[0028] Such as Figure 1 to Figure 5 As shown, the present invention introduces a large-diameter nailhead wire filling device, wherein the large diameter refers to the nailhead wire diameter above 5.5mm, including the nailhead wire sorting plate, the blocking piece and the nailhead wire filling strip.

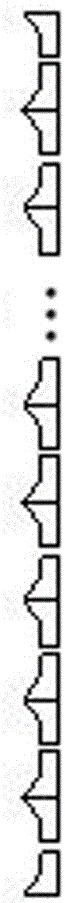

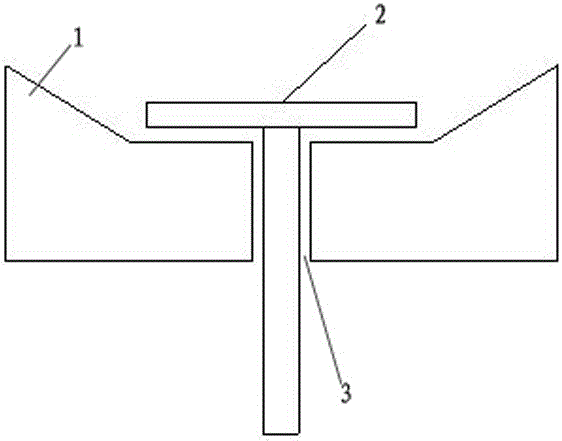

[0029] The nailhead sorting board includes a board body 5 on which there are N lanes of nailhead lead slides 6 parallel to each other and arranged at equal intervals. The nailhead lead slides are used for hanging the nailhead leads and guiding the movement of the nailhead leads. Ridges 1 are formed on both sides of the nailhead lead wire slideway to increase the probability that the nailhead lead wire 2 enters the nailhead lead wire slideway. Each nailhead lead slideway includes a groove 3 in the middle and supporting parts on both sides of the groove, the supporting part is used for supporting the nailhead lead wire nailhead, and the groove is used for accommodating the nailhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com