Heat exchanger device for egr systems

A recirculation system and heat exchanger technology, applied in the direction of exhaust gas recirculation, heat exchange equipment, heat exchange equipment safety devices, etc., to achieve the effect of smooth temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

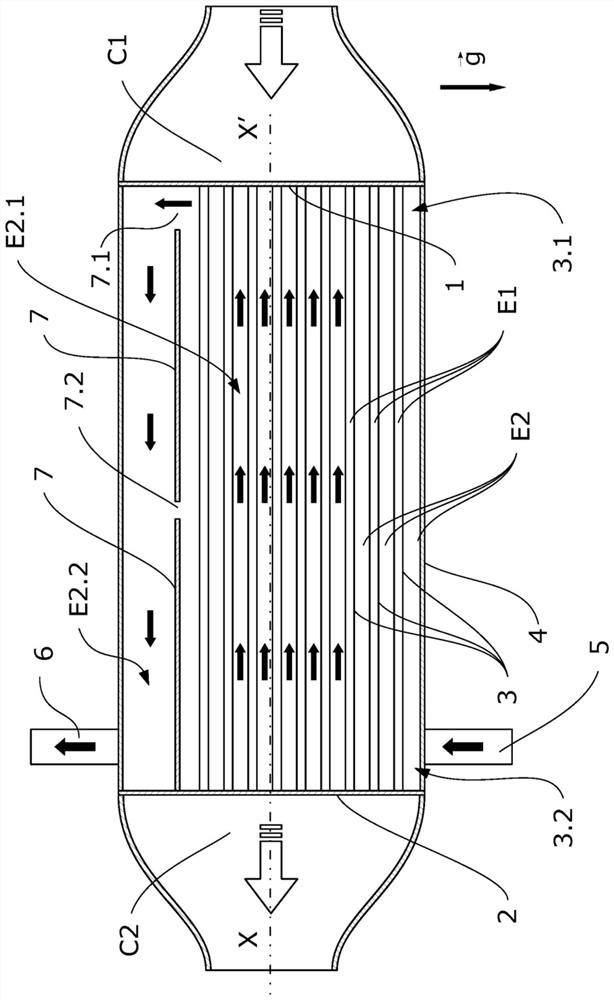

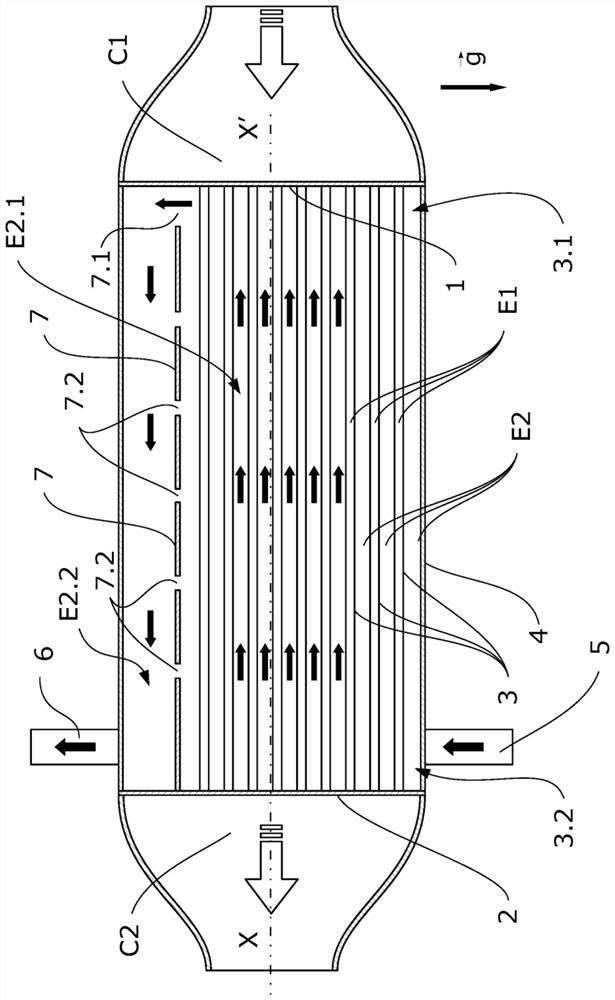

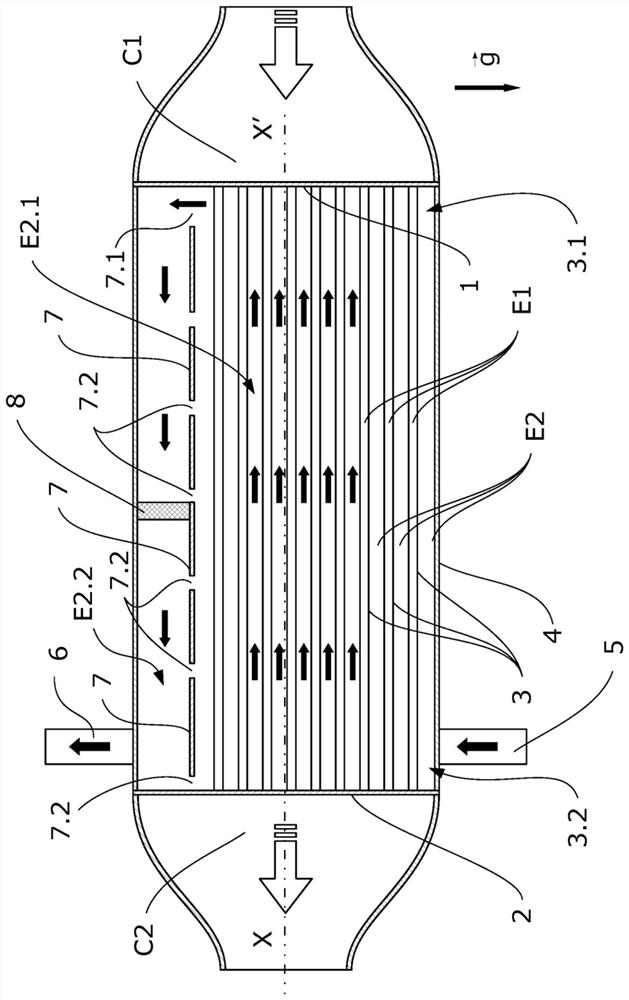

[0065] According to a first inventive aspect, the invention relates to a device for exchanging heat in an EGR system, wherein the temperature of a portion of the hot gas coming from the combustion chamber, identified as the first fluid, must be reduced in order to be able to It is reintroduced into the air intake, reducing the amount of nitrogen oxides in the exhaust.

[0066] The heat exchange device described has said purpose, wherein heat from a first fluid is dissipated to a second fluid, namely a liquid coolant.

[0067] The described embodiments solve the identified problems caused by the boiling of the liquid coolant in contact with the hotter surfaces where the heat exchange takes place, particularly in baffles that directly receive the hot gas.

[0068] figure 1 is a schematic view of a first embodiment of the invention, depicting a longitudinal section of a heat exchanger according to this first example.

[0069] The heat exchanger comprises a hot gas inlet, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com