Diesel particulate trap coated with noble metal and non-noble metal catalysts in different areas and preparation method thereof

A precious metal catalyst, particle trap technology, applied in mechanical equipment, machine/engine, engine components, etc., can solve the problem of low emission reduction effect in the low temperature and cold start stage of the engine, and achieve sustainable development and good light-off. Active and oxygen storage capacity, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

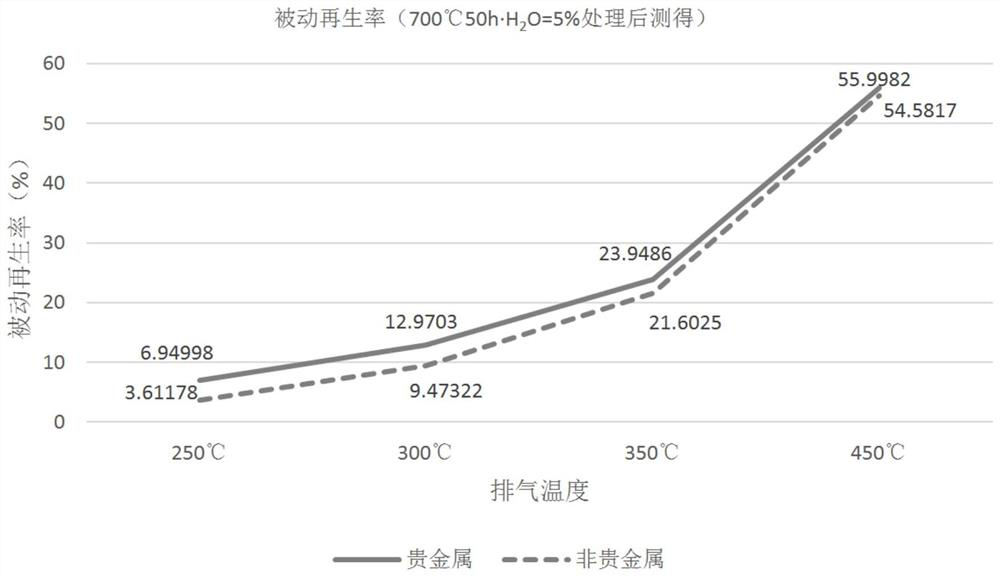

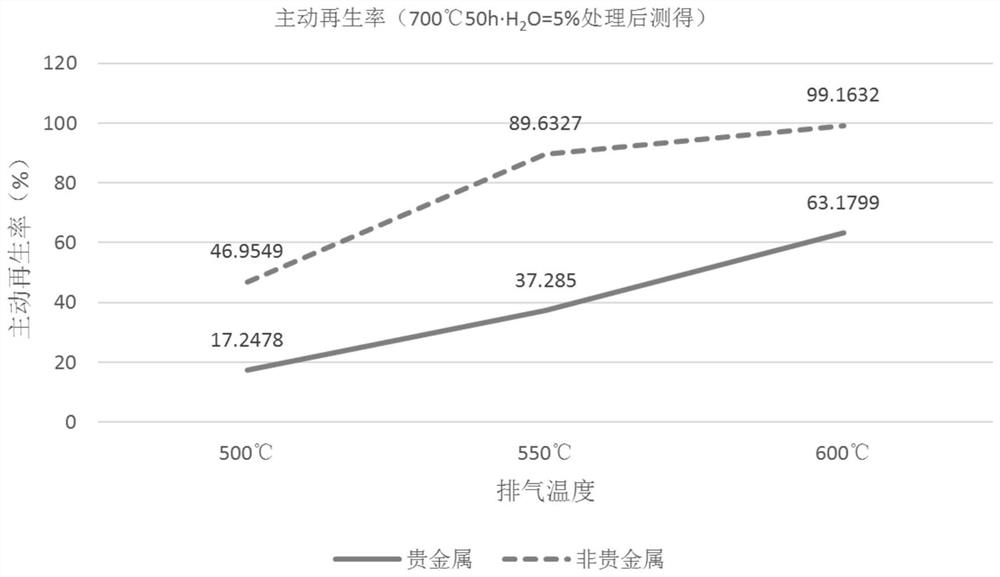

[0039] Firstly, by analyzing the particle emission test data of a single diesel particulate filter coated with a noble metal catalyst and a non-precious metal catalyst, the catalytic performance of the noble metal catalyst and the non-precious metal catalyst is compared:

[0040] Passive regeneration: if figure 1 It can be seen that the catalytic efficiency of noble metal catalysts is slightly higher than that of non-noble metal catalysts under low temperature (250°C-450°C) passive regeneration environment. On the other hand, as the temperature rises, the catalytic performance of the non-precious metal catalysts is gradually equal to that of the noble metal catalysts.

[0041] Active regeneration: if figure 2 As shown, the non-noble metal DPF exhibits very good regeneration efficiency at 550 °C, and can achieve active regeneration at lower temperatures. In the whole stage of active regeneration, the catalytic efficiency of non-noble metal catalysts is significantly ahead of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com