A kind of nano-organic silicon film-forming hydrophobic shale surface hydration inhibitor and its preparation method and application

A technology of hydration inhibitor and nano-organosilicon, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient wettability change, poor inhibition performance, poor compatibility, etc., and achieve good compatibility , low filtration performance, and the effect of reducing free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

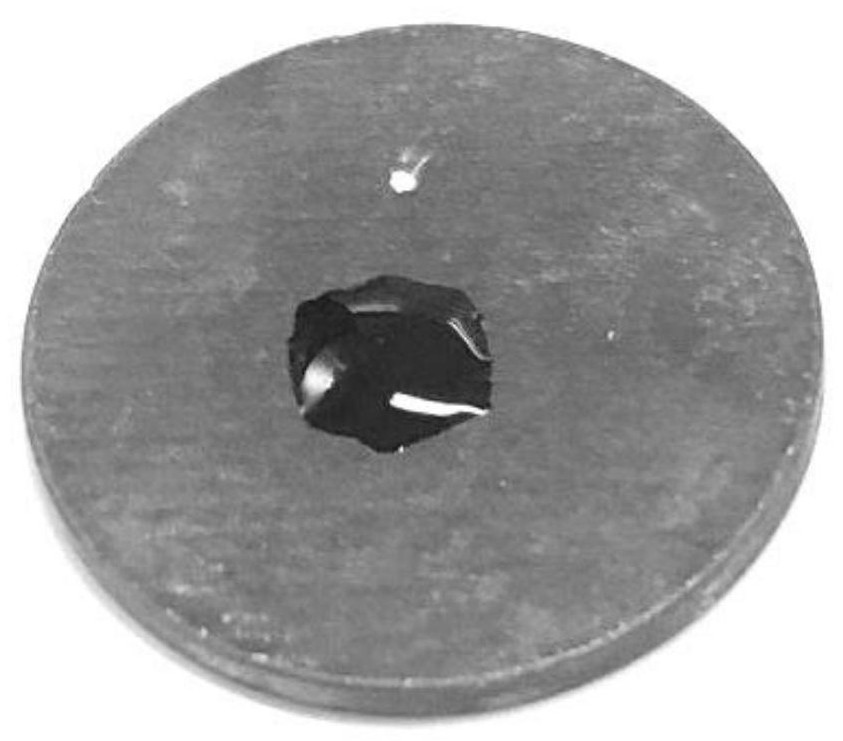

Image

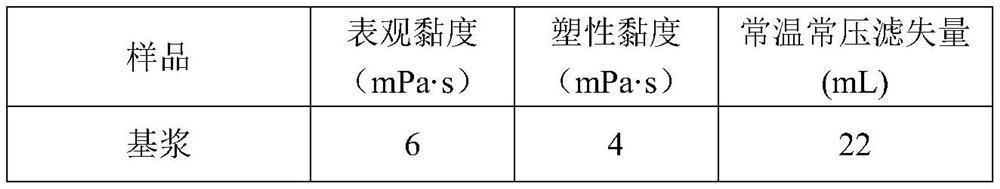

Examples

Embodiment 1

[0034] A method for preparing a nano-organosilicon film-forming hydrophobic shale surface hydration inhibitor, comprising the following steps:

[0035] (1) Under the stirring condition of the stirring speed of 300 r / min, 10 g of nano-silica was added to the mixed solvent of 100 mL of water and 20 mL of ethanol, and then ultrasonically dispersed for 0.5 h at room temperature; after the ultrasonic wave was over, the obtained solution was transferred. into a three-necked flask, slowly stir at a stirring speed of 300 r / min, and use a 20% NaOH aqueous solution to adjust the pH of the system to 9 to obtain mixed solution A.

[0036] (2) 5g octyltriethoxysilane was added to 20g ethanol to prepare a long-chain organosilicon solution; then the long-chain organosilicon solution was added dropwise to the mixed solution A obtained in step (1), and the dropping time was 20min ; Then at 40°C, under the condition of stirring speed of 200r / min, react for 1h to obtain mixed solution B.

[003...

Embodiment 2

[0039] A method for preparing a nano-organosilicon film-forming hydrophobic shale surface hydration inhibitor, comprising the following steps:

[0040] (1) Under the stirring condition of the stirring speed of 300 r / min, 10 g of nano-silica was added to the mixed solvent of 100 mL of water and 20 mL of ethanol, and then ultrasonically dispersed for 0.5 h at room temperature; after the ultrasonic wave was over, the obtained solution was transferred. into a three-necked flask, slowly stir at a stirring speed of 300 r / min, and use a 20% NaOH aqueous solution to adjust the pH of the system to 9 to obtain mixed solution A.

[0041] (2) 5g of dodecyl trimethoxysilane is added to 20g of ethanol to prepare a long-chain organosilicon solution; then the long-chain organosilicon solution is slowly added dropwise to the mixed solution A obtained in step (1), and the addition time After 20 min at 60°C, the reaction was carried out for 1 h at a stirring speed of 200 r / min to obtain mixed so...

Embodiment 3

[0044] A method for preparing a nano-organosilicon film-forming hydrophobic shale surface hydration inhibitor, comprising the following steps:

[0045] (1) Under the stirring condition of the stirring speed of 300 r / min, add 10 g of nano calcium carbonate to a mixed solvent of 100 mL of water and 20 mL of ethanol, and then ultrasonically disperse at room temperature for 0.5 h; In the three-necked flask, slowly stir at a stirring speed of 300 r / min, and adjust the pH of the system to 9 with an aqueous NaOH solution with a mass fraction of 20% to obtain a mixed solution A.

[0046] (2) 5g of hexadecyltrimethoxysilane was added to 20g of ethanol to prepare a long-chain organosilicon solution; then the long-chain organosilicon solution was slowly added dropwise to the mixed solution A obtained in step (1), and the addition time for 20 min, and then at 40° C. and under the condition of a stirring speed of 200 r / min, the reaction was carried out for 1 h to obtain mixed solution B. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com