Double pallet fork device for unmanned forklift

A technology of unmanned forklifts and forks, applied to double forks. It can solve the problems of low work efficiency and unstable fixation, and achieve the effect of stable transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

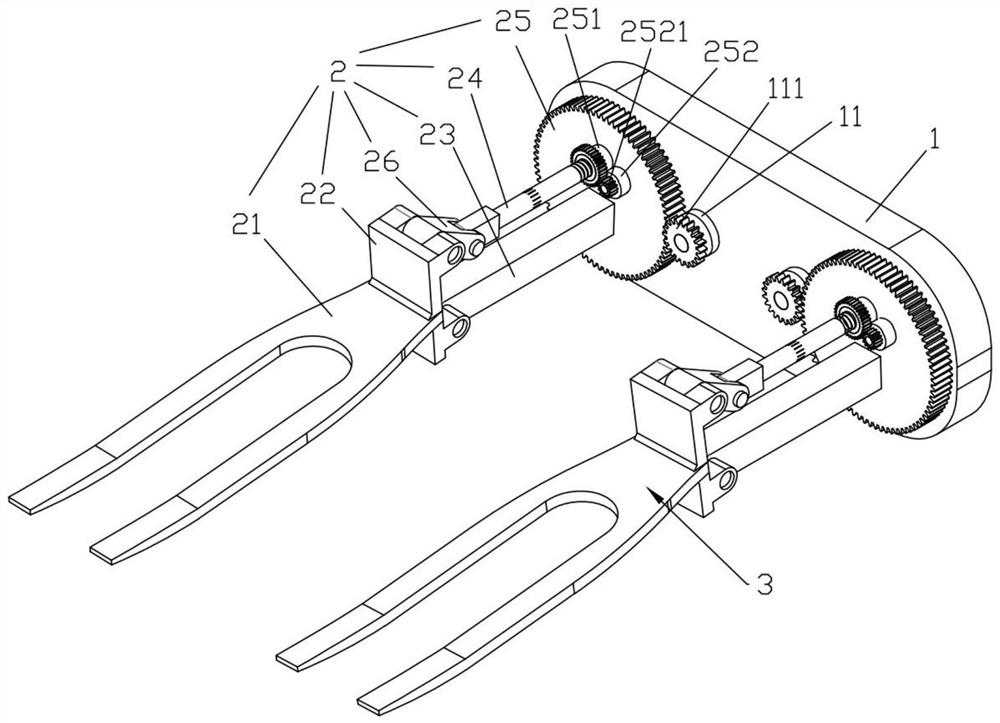

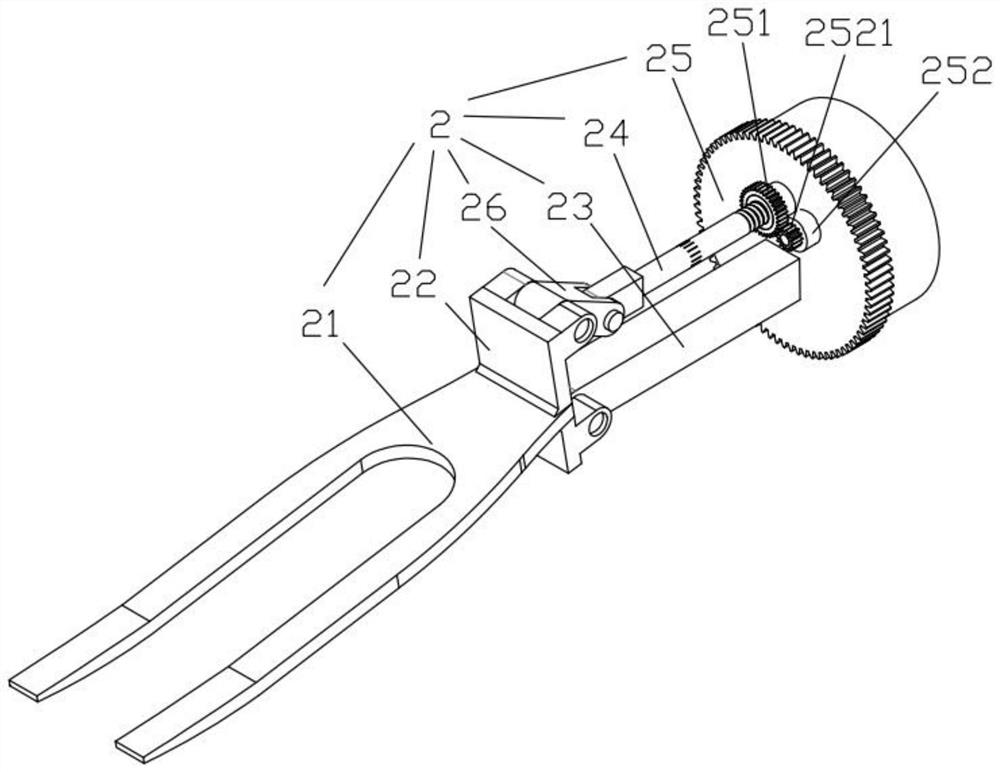

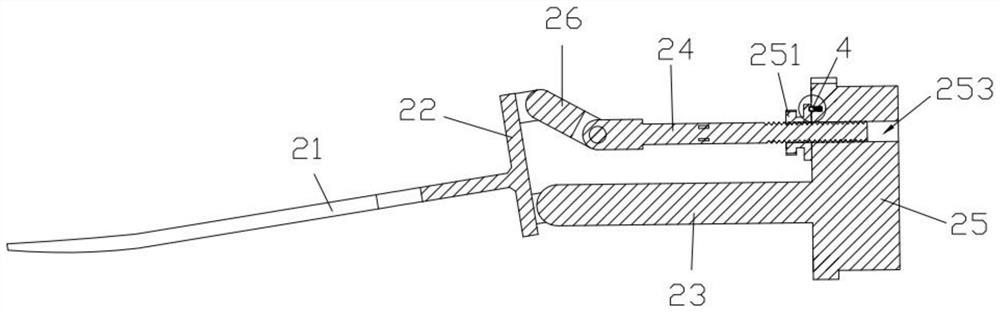

[0023]Such asFigure 1 - Figure 4As shown: a double trunch for a forklift, including a lifting assembly and a mounting base 1 disposed on the lifting assembly, and the side surface of the mounting base 1 is provided with a first carousel. Fork 2 and second fork 3;

[0024]The structures of the first fork 2 and the second ferrule 3 include the fork body 21, the connection disk 22, the stabilizer rod 23, the adjustment lever 24, and the rotary disk 25, the root of the connecting disk 22 and the root of the fork main body 21. The fixed connection, the fork body 21 is a Y-shaped, the root is a metal rod, and the end is two metal rods, and one end of the other side of the connecting disk 22 and one end of the stabilizing rod 23 is hinged, and the other side of the disk 22 The other end is connected to the adjustment lever 24 through the link 26, and both ends of the link 26 respectively hinge the adjustment lever 24 and the connecting disk 22, and the other end of the stabilizer 23 is perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com