Steel wire rope erecting method for surveying underground pipe culverts

A wire rope and pipe culvert technology, which is applied to special pipes, pipe components, mechanical equipment, etc., can solve the problem that the pipe and culvert detection robot cannot be equipped with multiple detection equipment, and achieve the effect of high cost performance and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The invention provides a wire rope erection method for surveying underground pipe culverts, which is specifically implemented according to the following steps:

[0030] Step 1, select survey pipes and culverts, and determine the lowering end and recovery end of the detection equipment;

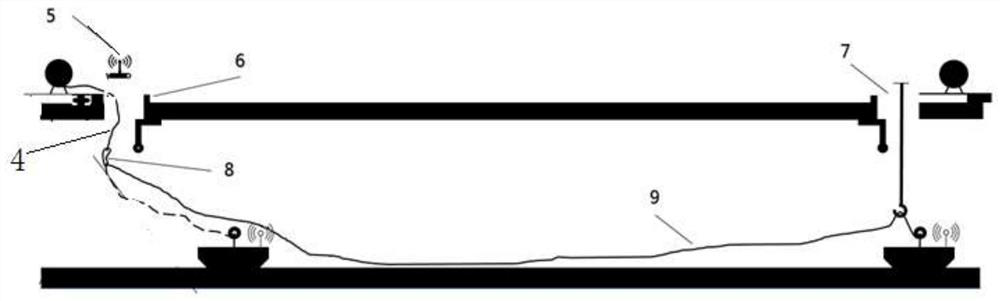

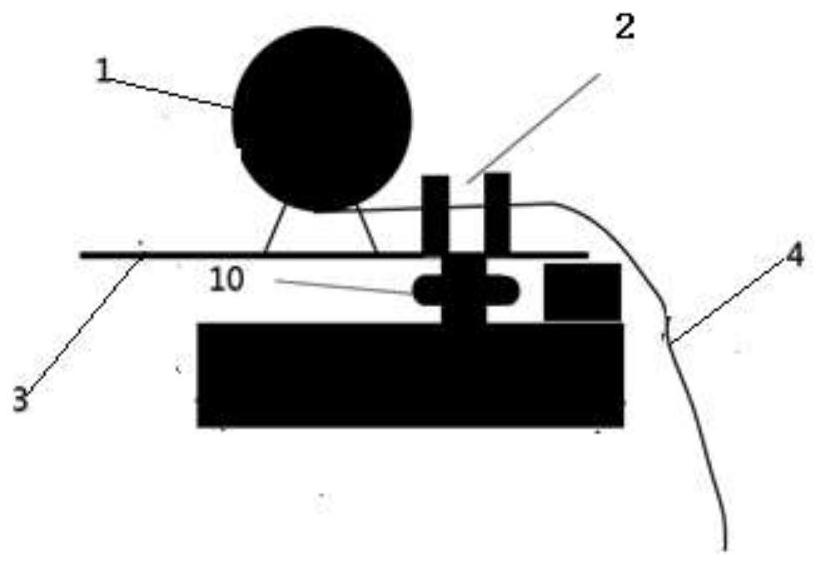

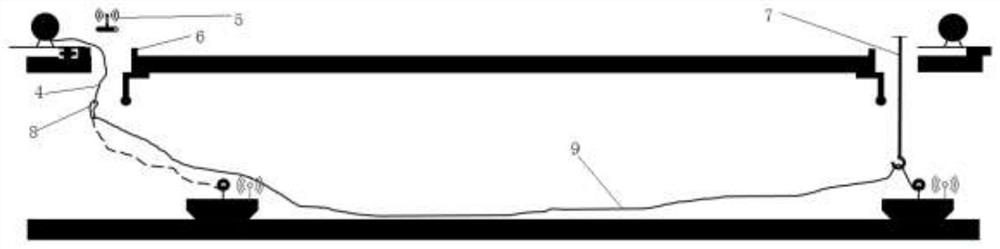

[0031] Step 2, such as figure 1 As shown, one end of the steel cable 4 is fixed on the lowering port; the steel cable 4 is fixed on the lowering port through the steel cable winch 1, one end of the steel cable 4 is fixed on the steel cable winch 1, and the other end of the steel cable 4 is stretched into the pipe culvert. There is also a winch holding force platform 3 between the cable winch 1 and the lowering port, which is used to tighten the steel cable 4, and a steering roller block clamp 6 is also arranged at the lowering port, and the steel cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com