Ultrathin adhesive tape preparation method and thickness adjusting device

A thickness adjustment and tape technology, which is applied in spraying devices, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as thickness adjustment and control need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

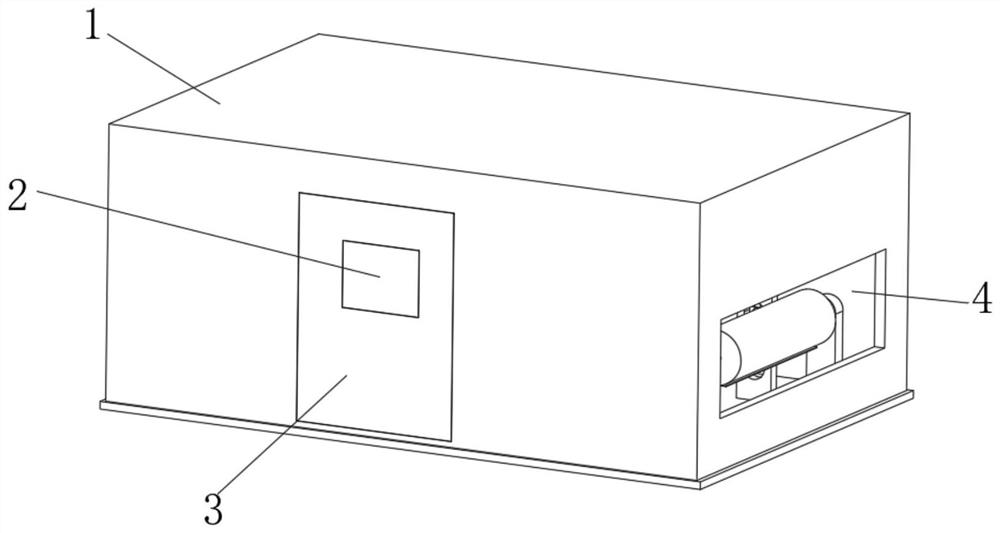

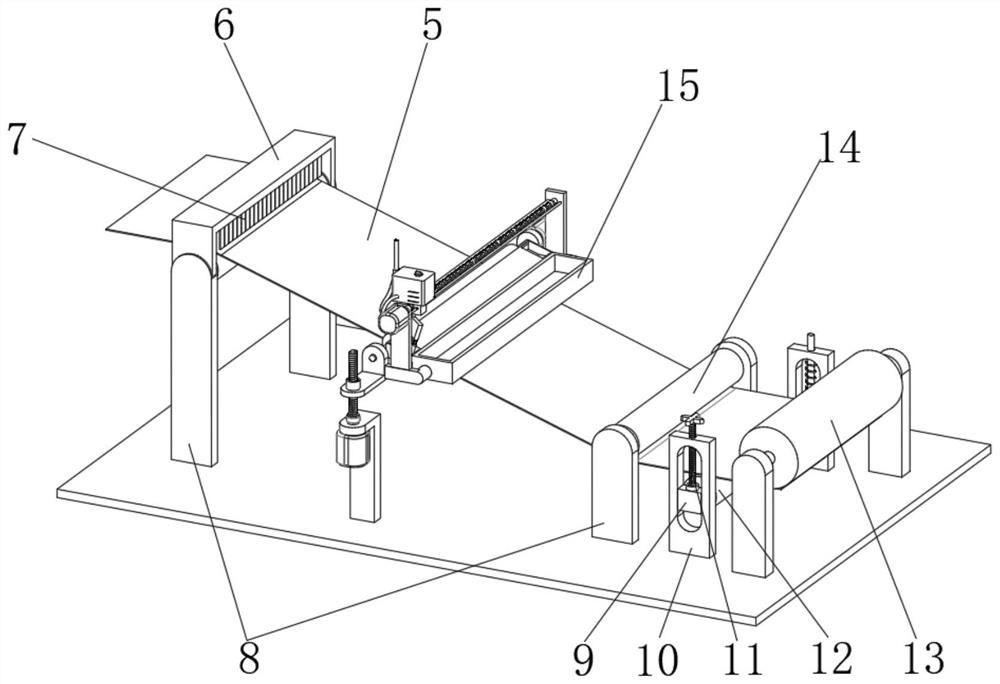

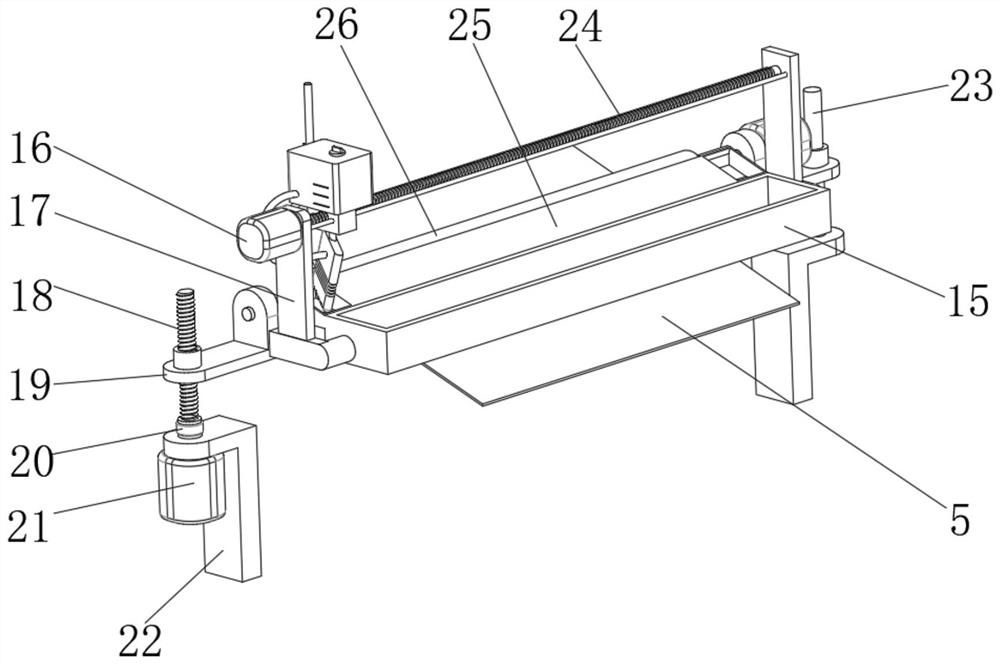

[0041] A device for adjusting the thickness of ultra-thin adhesive tape, such as Figure 1-7 As shown, it includes a squeegee mechanism installed inside the clean room 1 and two first support frames 22, the outer wall of the top of one of the first support frames 22 is rotatably mounted with an adjustment screw 18, and the top of the other first support frame 22 is The outer wall is fixed with an adjustment guide rod 23 by screws, one outer wall of the first support frame 22 is fixed with a servo adjustment motor 21 by screws, the adjustment stud 18 is rotatably connected to the output end of the servo adjustment motor 21, and the scraping mechanism includes a scraper The rubber roller 26 and two adjustment frames 19, the rubber scraping roller 26 are installed on the inner walls of the two adjustment frames 19 through the shaft rotation respectively, one adjustment frame 19 is connected to the outer wall of the adjustment stud 18 by thread, and the other adjustment frame 19 is...

Embodiment 2

[0051] A kind of ultra-thin adhesive tape preparation method, such as Figure 1-7 shown, including the following steps:

[0052] S1: pulling one end of the adhesive tape base film 5 to the winding drum 13 and fixing it;

[0053] S2: adjust the parameters through the control panel 2, so that the servo adjustment motor 21 controls the rotation of the adjustment screw 18 to adjust the distance between the squeegee roller 26 and the tape base film 5;

[0054] S3: adjust the height of the lifting roller 12 through the lifting knob 11, and control the tension degree of the tape base film 5;

[0055] S4: Control the feeding of the base film 5 of the tape, the glue spraying mechanism sprays the adhesive on the top surface of the base film 5 of the tape, and the winding drum 13 winds up synchronously;

[0056] S5: Control the rotation of the scraping roller 26 to scrape off excess adhesive;

[0057] S6: Periodically control the operation of the scraper motor 16, and use the translat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com