Balanced crushing control technology in sand and gravel production

A kind of sand and gravel, balanced technology, applied in the field of balanced crushing control process in sand and gravel production, can solve the problems of difficulty in meeting the requirements of sand and gravel aggregate quantity and aggregate quality, low-efficiency operation, low production capacity of small stones, etc., so as to reduce production capacity. Coordinate matching difficulty and complexity, improve efficiency, and facilitate the effect of proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

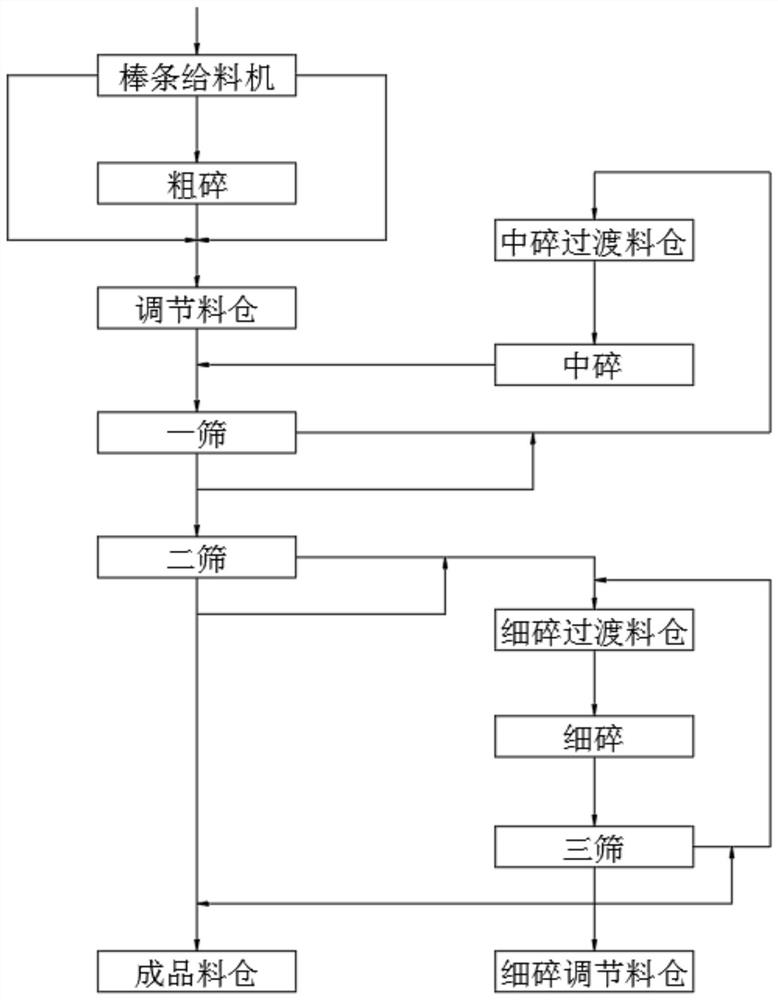

[0024] The invention provides a balanced crushing control process in sand and gravel production, which includes the following steps:

[0025] Step 1. Coarse crushing. Raw materials enter the jaw crusher through the rod feeder for coarse crushing. After coarse crushing, they are stored in the adjustment silo. Adjust the gap between the rods of the rod feeder so that some small stones enter the crusher. Fill the gap between large stones, and adjust the discharge gap of the jaw crusher accordingly, so that the output of coarse crushing can match the subsequent processing links;

[0026] Step 2, first sieve, adjust the stone in the silo to be transported to the first sieve, the coarse material of the first sieve enters the intermediate crushing transition silo for storage, the stone in the intermediate crushing transition silo enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com