Sausage processing method for radio frequency sterilization assisted by superheated water

A processing method and superheated water technology, applied in food heat treatment, meat/fish preservation, heating preservation of meat/fish, etc., can solve the problems of no combined sterilization method, poor heating uniformity, single sterilization method, etc., and achieve improvement The effect of product processing capacity, improvement of production efficiency and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

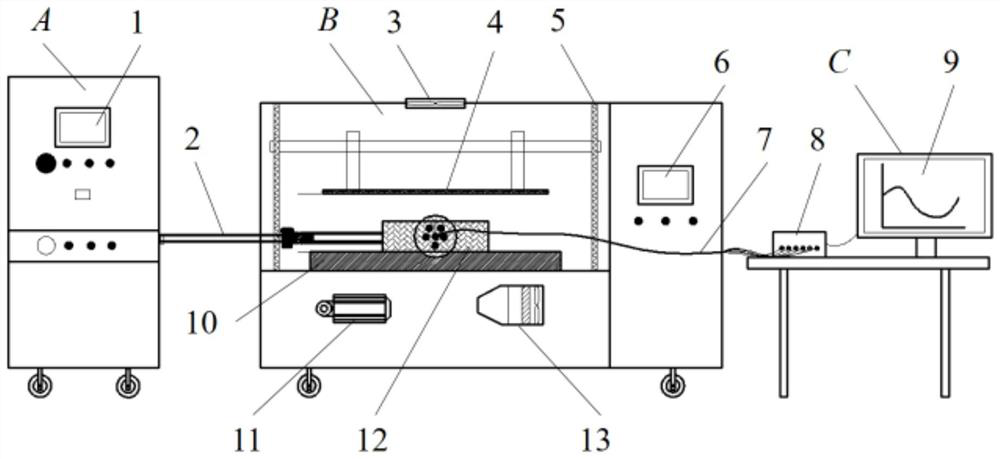

[0071] Example 1, Determination of heating stability and heating rate of pure water bath of radio frequency sterilization auxiliary system

[0072] (1) Soak 250g of beef in fat-free oil for 1-2 hours (change the water once in the middle), add 5g of shallot, 5g of ginger, and 10g of carrot, mix well and put it in a blender (high speed 10s, low speed 30s) to get meat stuffing;

[0073] (2) After taking out the meat stuffing, add 4g salt, 5g light soy sauce, 10g wheat starch, 10g corn starch, 10g potato starch, 2g essence, and an egg (55±1g), mix well, let it stand for 30 minutes, and use collagen sausage casing filling;

[0074] (3) Prick the filled beef sausage with a toothpick into multiple holes, put it in a steamer and steam it at 80w power for 1 hour (turn it over every 20 minutes), take it out quickly after steaming, let it cool naturally, and wrap it in a sterile plastic film Store in the refrigerator at 4°C for later use;

[0075] (4) Sterilize the sausage with superhe...

Embodiment 2

[0077] Example 2, Beef Sausage Superheated Water Assisted Radio Frequency Sterilization Heating Stability and Heating Rate Determination

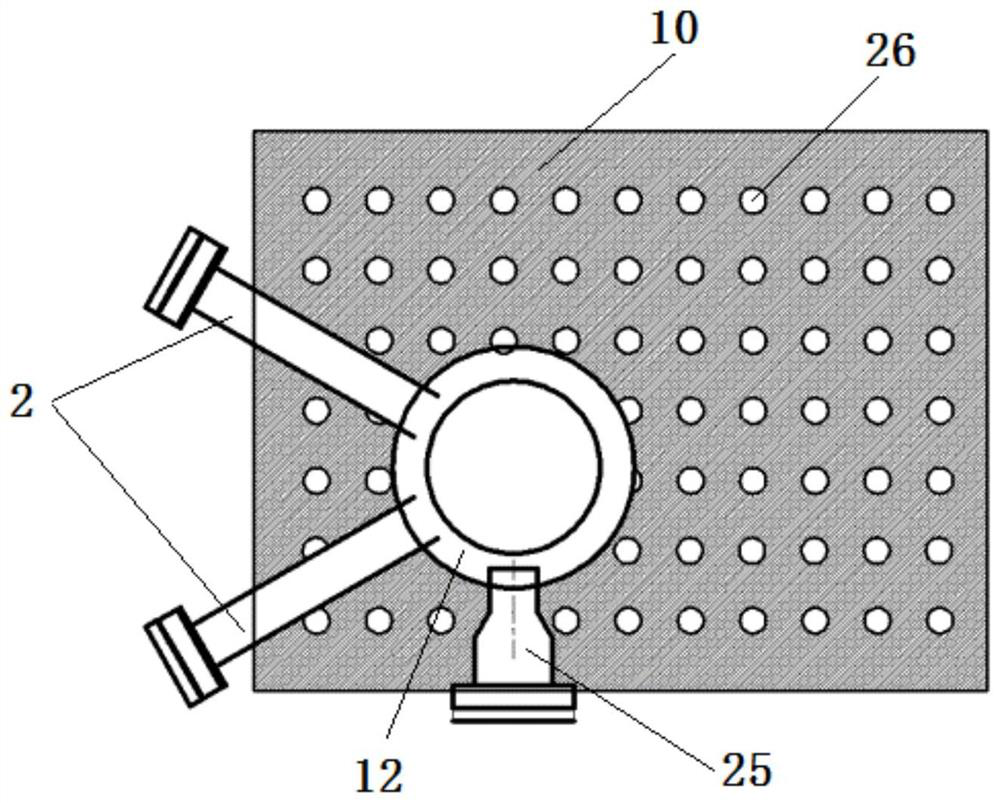

[0078] Place the pretreated material in the retort 12 according to Example 1, start the superheated water sterilization auxiliary system A and start the radio frequency generator B1 at the same time, adjust the distance between the upper electrode plate 4 and the lower electrode plate 10 to 165 ~ 200mm, set The superheated water sterilization auxiliary system control panel 1 parameter is 100, 110, 120 ° C for 25 minutes, and the temperature rise curve is recorded through the computer optical fiber temperature measurement system C. According to the test results, the distance between the upper electrode plate 4 and the lower electrode plate 10 is 180mm, the superheated water sterilization auxiliary system control panel 1 parameter is set to 120°C for 25 minutes, and the height of the material is 85mm. Superheated water sterilization auxiliary ...

Embodiment 3

[0079] Embodiment 3, superheated water assisted radio frequency processing sterilization kinetics determination

[0080] According to the optimal sterilization process condition obtained in Example 2, injecting 100 μ L of Bacillus stearothermophilus spore suspension into the cold spot of beef sausage (10 mm from the top of the material) at a height of 85 mm, put it into Example 2 after aseptic packaging The sterilizer 12 placed in the superheated water sterilization auxiliary system control panel 1 is set at a temperature of 120°C, the holding time is 0, 10, 20, and 30min, and the distance between the upper electrode plate 4 and the lower electrode plate 10 is 180mm. Conduct a bactericidal test. The result is as Figure 5 As shown, when the temperature is lower than 110°C, the sterilization effect of superheated water combined with radio frequency is not obvious; when the temperature is 110-120°C, as the temperature increases, the sterilization effect is better; and superheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com