Semiconductor wafer expander

A semiconductor and wafer technology, which is applied in the field of semiconductor wafer expanders, can solve the problems of affecting the expansion efficiency and uneven heating of the film, and achieve the effects of avoiding alignment offset, avoiding direct contact, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

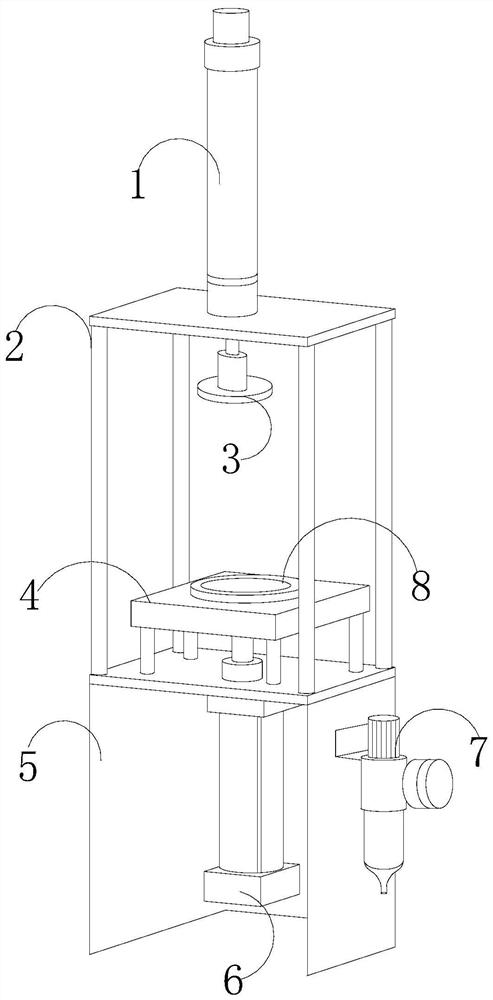

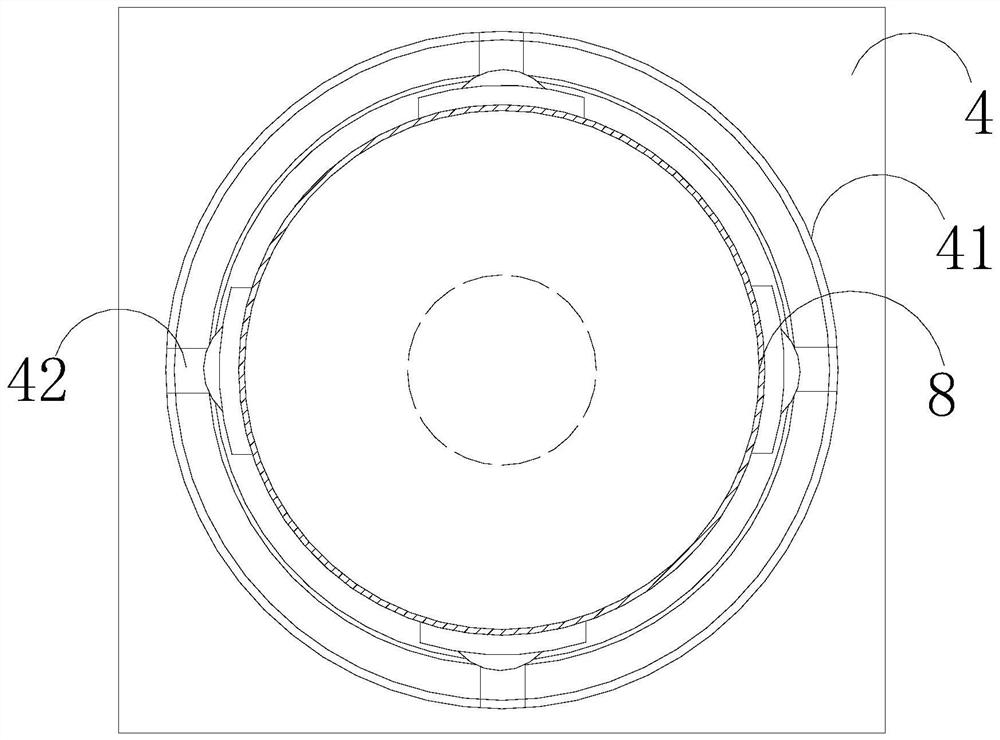

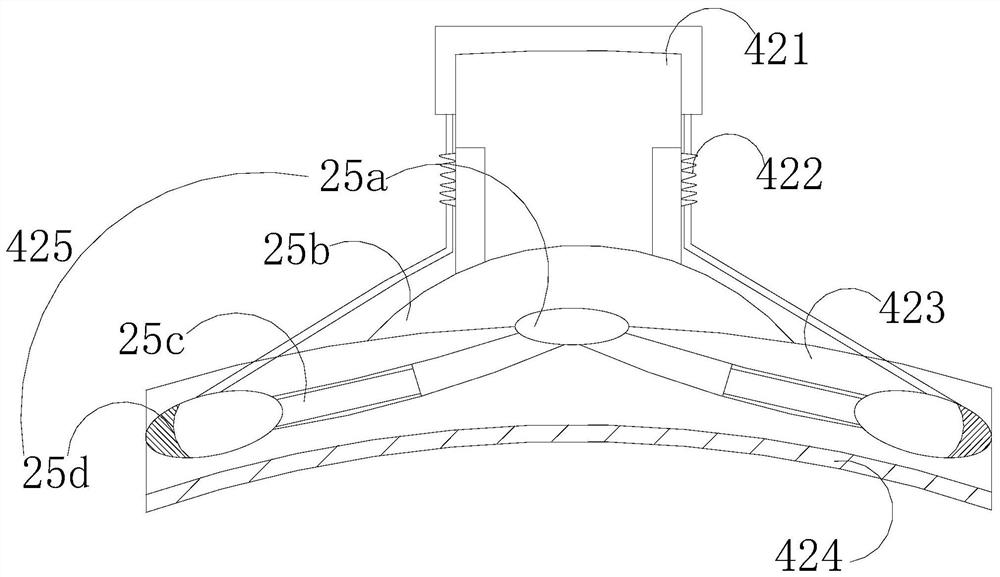

[0025] Such as Figure 1-Figure 6 As shown, the present invention provides a semiconductor wafer expander, the structure of which includes a first cylinder 1, a frame 2, an upper disk 3, a support base 4, a fixed frame 5, a second cylinder 6, a heater 7, a heating Disc 8, four frames 2 are welded on the fixed frame 5, a rectangular plate is welded on the upper end of the frame 2, a first cylinder 1 is installed above the rectangular plate, and the first cylinder 1 is connected to the upper circle The disc 3 is mechanically connected, the upper disc 3 is vertically opposite to the heating disc 8 and the supporting base 4, the supporting base 4 is provided with a heating disc 8, and the supporting base 4 is mechanically connected to the fixed frame 5, The support base 4 is connected to the second cylinder 6, the heater 7 is electrically connected to the heating disc 8, the support base 4 is provided with a tray 41 and a positioning device 42, and the tray 41 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com