Bundle assembly for superconducting tape encapsulation and device for preparing high-temperature superconducting tape with inner-encapsulated optical fiber

A technology of superconducting tape and clustering, applied in superconducting/high-conducting conductors, superconducting devices, usage of superconducting elements, etc. Complete appearance, meet adjustment requirements, and improve the effect of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

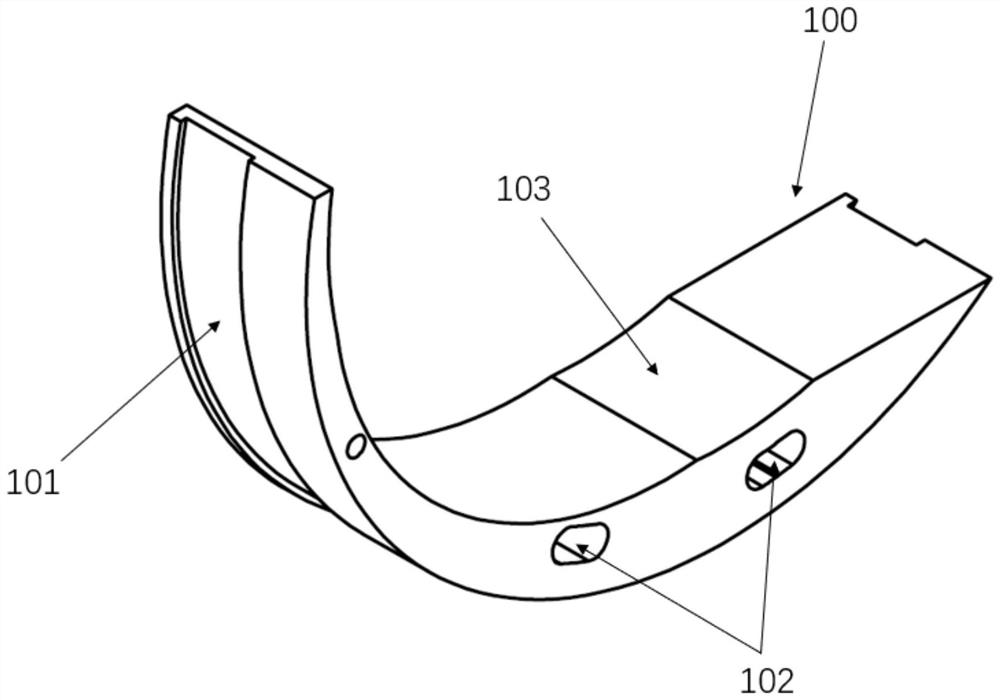

[0038] The embodiment of the present invention provides a cluster plate 100 mainly used for superconducting tape packaging. The cluster plate 100 is an arc-shaped structural plate. Preferably, the length of the arc segment of the cluster plate 100 is greater than or equal to a quarter of the circumference At the same time, a guide and limit groove 101 is provided on the outer surface of the cluster plate 100 in the circumferential direction, and the guide and limit groove 101 penetrates from one end of the cluster plate 100 to the other end. The guiding and limiting groove 101 may be disposed close to one side of the cluster plate 100 , or may be disposed along the middle of the cluster plate 100 . The guide and limit grooves 101 are used for placing wire harnesses such as upper and lower metal packaging tapes, superconducting tapes, and measuring optical fibers, so that the wire harnesses slide in and along the guide and limit grooves 101 . The arc-shaped cluster plate 100 is...

Embodiment 2

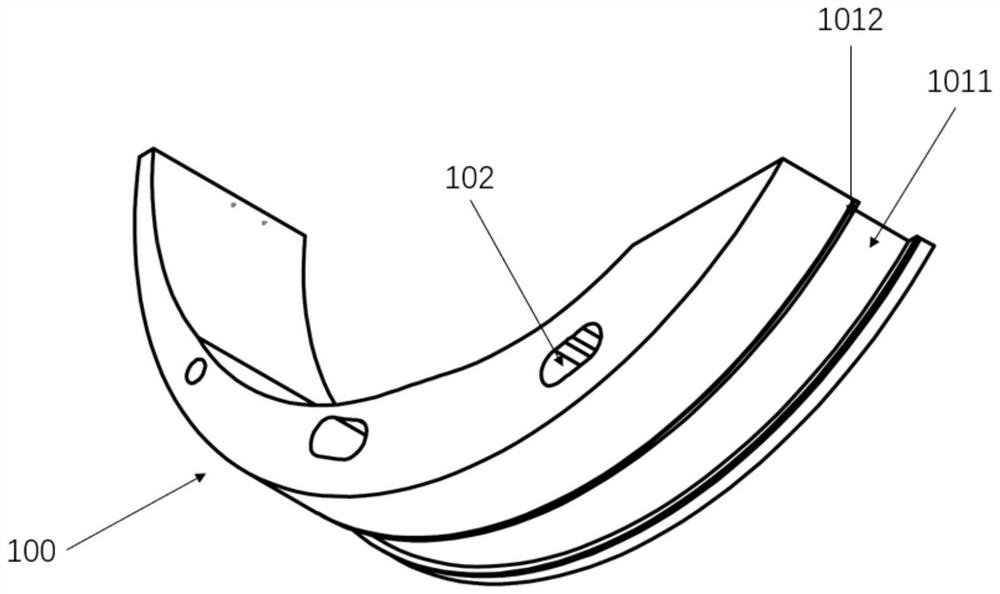

[0042] The second embodiment is formed on the basis of the first embodiment. Through the optimized design of the structure of the clustering plate, the thickness of the clustering plate at the exit end of the guide limit groove reaches a predetermined thickness, which meets the requirements between superconducting strips or superconducting strips. The gap between the material and the packaging tape is required to improve the packaging effect of the superconducting tape. In addition, the adjustability of the spacing between the tapes improves the adaptability to different types of tapes. specifically:

[0043] The thickness of the bundling plate 100 is designed to be thin as a whole. The thickness of the bundling plate 100 from the inlet end of the guide limiting slot 101 to the outlet end of the bundling plate 100 decreases from thick to thin until the outlet end of the guide limiting slot 101 reaches a preset thickness. Here, the so-called thickness of the cluster plate 100 is ...

Embodiment 3

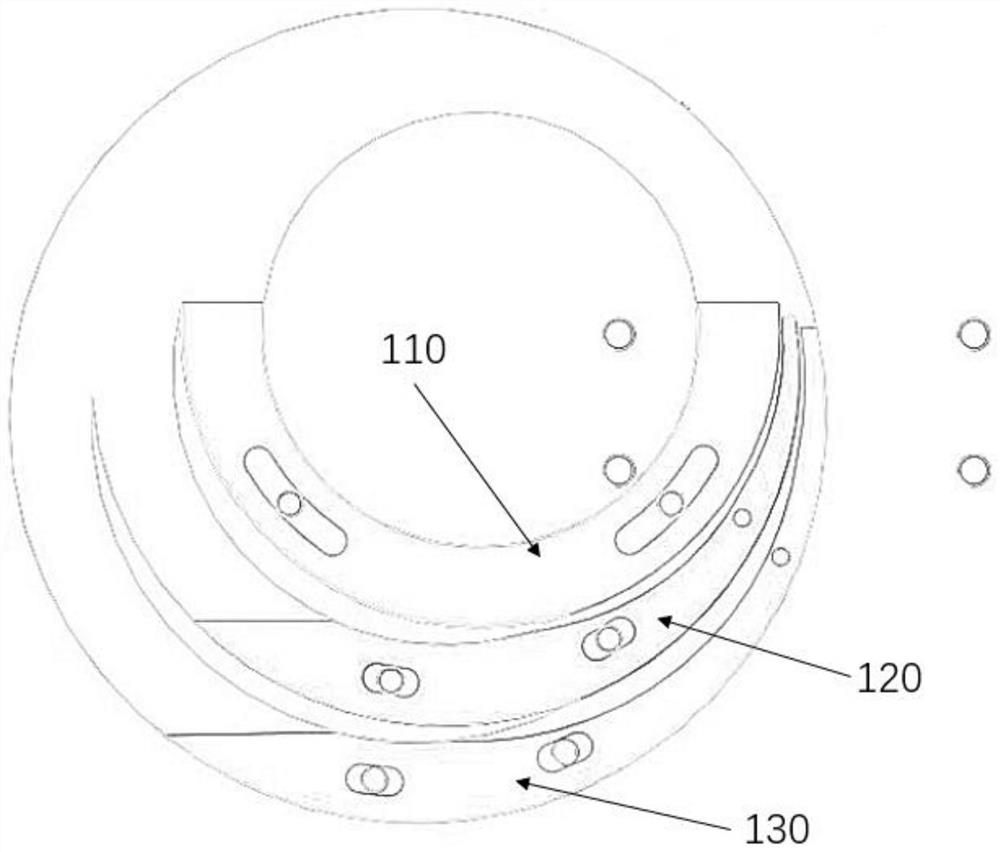

[0047] The third embodiment is a clustering assembly formed on the basis of the first or second embodiment. The clustering assembly mainly includes three clustering plates 100, which are respectively denoted as the first clustering plate 110, the second clustering plate 120 and the third clustering plate 100. For the clustering plate 130, three clustering plates are stacked in sequence from top to bottom, the first clustering plate 110 is located on the uppermost layer, the third clustering plate 130 is located at the bottommost layer, and the second clustering plate 120 is located in the middle layer. The three clustering plates are slidably arranged, that is, the outer peripheral surface of the first clustering plate 110 is located on the inner peripheral surface of the second clustering plate 130 , which can be located on the chute 103 on the inner peripheral surface of the second clustering plate 130 , or can be located on the sliding groove 103 of the second clustering plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com