Apparatus for the automated production of glass assemblies and corresponding method

A technology for automatic production and glass, which is applied in glass manufacturing equipment, glass forming, glass reshaping, etc., and can solve problems such as manual labor and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

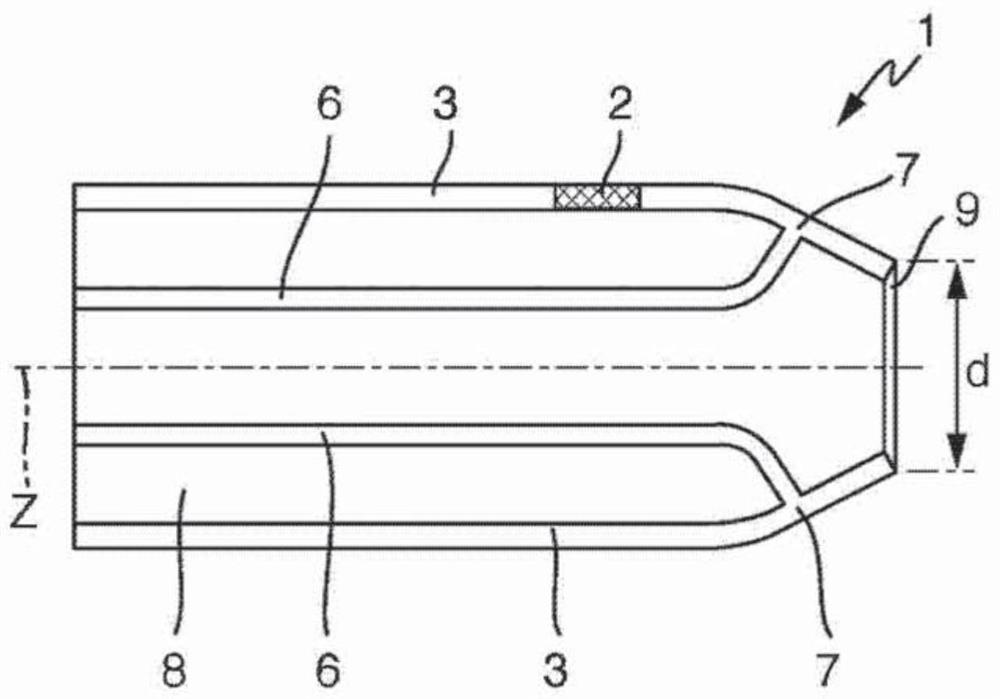

[0029] figure 1 A glass component 1 is schematically shown, which can be processed to produce a potentiometric sensor, in particular a pH sensor. The glass assembly 1 has an inner tube 6 and an outer tube 3 which are arranged coaxially with respect to their common axis of rotation Z. The membrane 2 is arranged in the tube wall of the outer tube 3 and is connected in a firmly bonded manner with the tube wall of the outer tube 3 by being fused into the tube wall. The diaphragm 2 is correspondingly formed from a cylindrical porous ceramic body.

[0030] At the connection point 7, the inner tube 6 and the outer tube 3 are fused together. The connection point 7 closes one end of the annular chamber 8 formed between the inner tube 6 and the outer tube 3 . The inner tube 6 is open at its end 9 in the region of the connection point 7 .

[0031] The production of a pH sensor with a glass electrode made of glass component 1 can be carried out, for example, in such a way that a pH-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com