Explosive substance solution critical explosion temperature testing container

A technology of explosion temperature and test container, which is applied in the direction of material explosion, can solve the problems of meaningless test results, inconvenient use, and large impact on results, and achieve the effects of easy calculation and processing, reduced experimental cost, and convenient adjustment of equivalent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

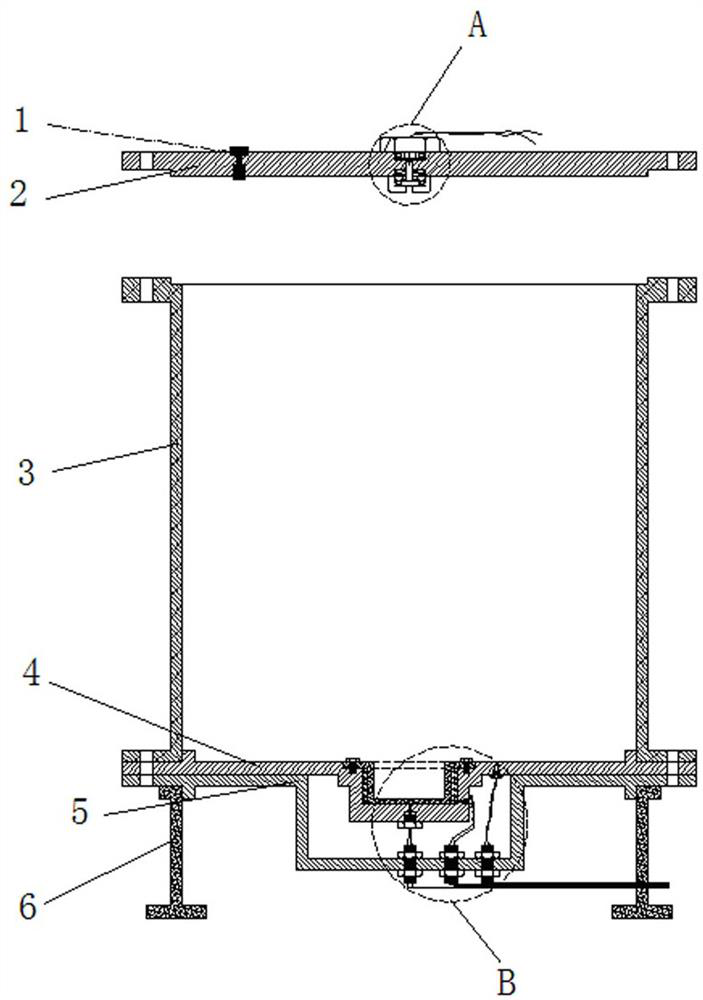

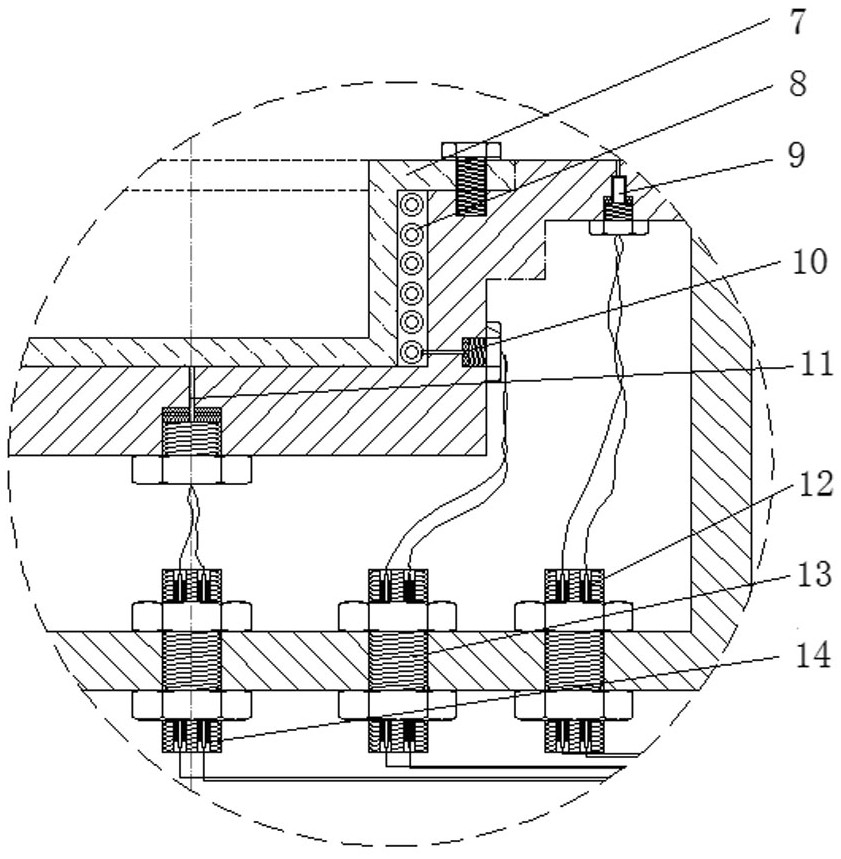

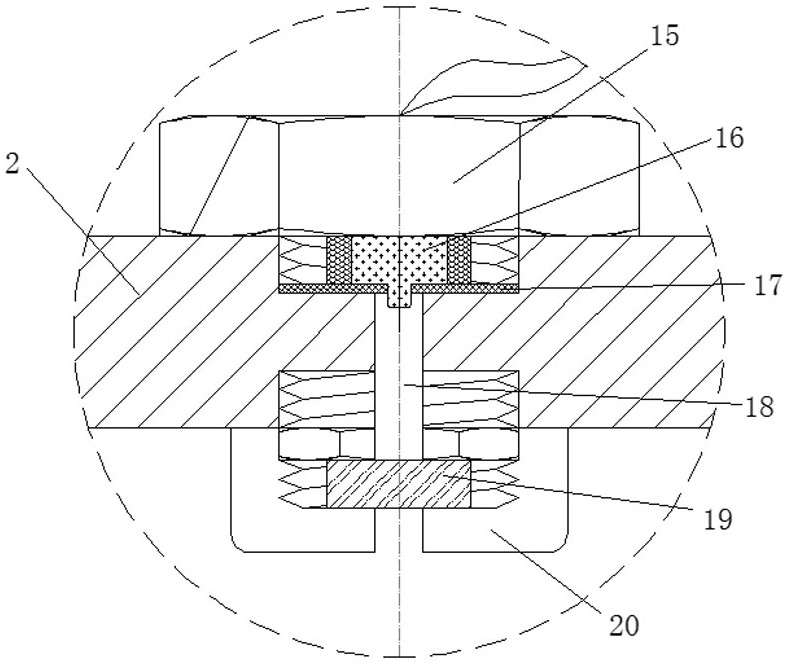

[0025] Such as figure 1 , 2 As shown in , 3, a test container for the critical explosion temperature of an explosive substance solution includes a container cylinder 3, a cylinder cover 2 and a cylinder bottom 4, and the cylinder cover 2 is provided with a pressure relief valve 1 and a non-contact infrared temperature sensor. The cylinder bottom 4 of the container cylinder 3 is provided with a reaction tank, a reaction tank 7 is arranged in the reaction tank, an electric heating wire 8 is provided outside the reaction tank 7, and a contact temperature sensor 11 is provided at the bottom of the reaction tank. The outer side of the temperature sensor 11 is a sealing device, and a pressure detection hole is provided on the bottom 4 of the container cylinder, and a pressure sensor 9 is arranged in the pressure detection hole, and the outer side of the pressure detection hole is a sealing device, and the cylinder cover 2 is provided with a sensor Hole 18, sensor hole 18 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com