Surface shock wave testing device under explosion environment and evaluation method

A test device, shock wave technology, applied in the direction of measuring blasting force, etc., can solve the problem of inaccurate damage assessment results, achieve accurate damage assessment results, accurate test results, and solve the effects of inaccurate test results and damage assessment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

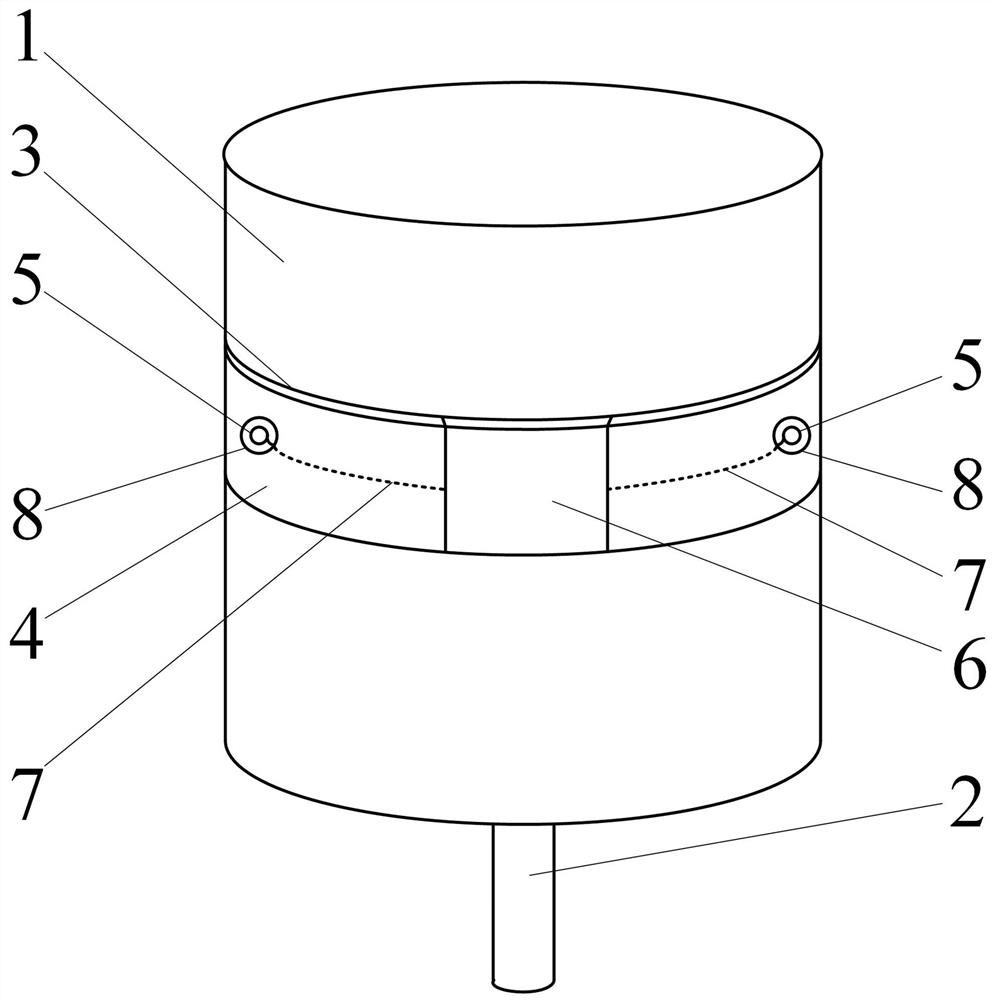

[0048]A surface shock wave testing device in an explosive environment, comprising a closed cavity 1, a support column 2, a flexible substrate 3, a flexible covering layer 4, four pressure sensors 5, a wireless data recorder 6, four wires 7, and a computer;

[0049] Wherein, the airtight cavity 1 is a cylindrical structure;

[0050] The support column 2 is vertically fixed at the center of the outer bottom surface of the airtight cavity 1;

[0051] The flexible substrate 3 is a strip-shaped structure; the flexible substrate 3 is hooped in the middle of the outer surface of the airtight cavity 1, and the two ends of the flexible substrate 3 are sewn together;

[0052] The flexible cover layer 4 is a strip-shaped structure; the flexible cover layer 4 is hooped on the outer side of the flexible substrate 3, and both ends of the flexible cover layer 4 are sewn together with the outer side of the flexible substrate 3; the flexible cover layer There is a distance between the two end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com