Graphene/carbon nanotube (CNTs) flexible pressure sensor and manufacturing method

A technology of pressure sensors and carbon nanotubes, which is applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of difficult operation and high cost, and achieve the effect of easy operation, adjustable size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

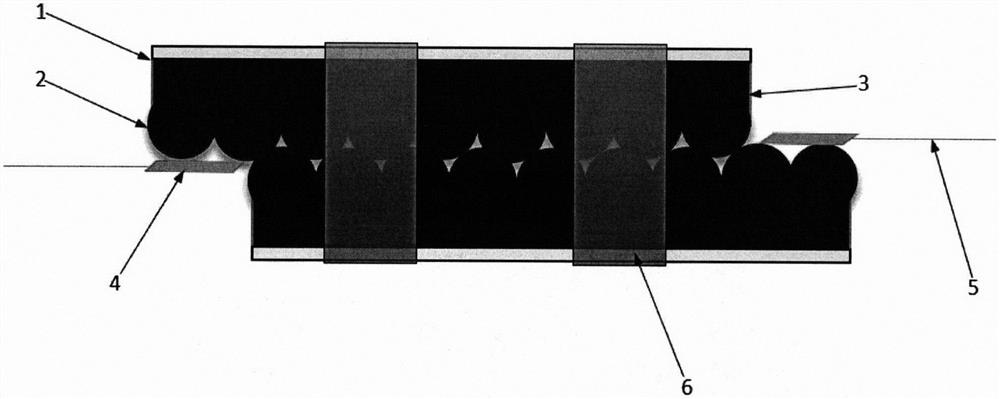

[0034] The ease of preparation of the PS microsphere array (2) and the influence on the sensitivity of the sensor are related to the diameter of the microspheres.

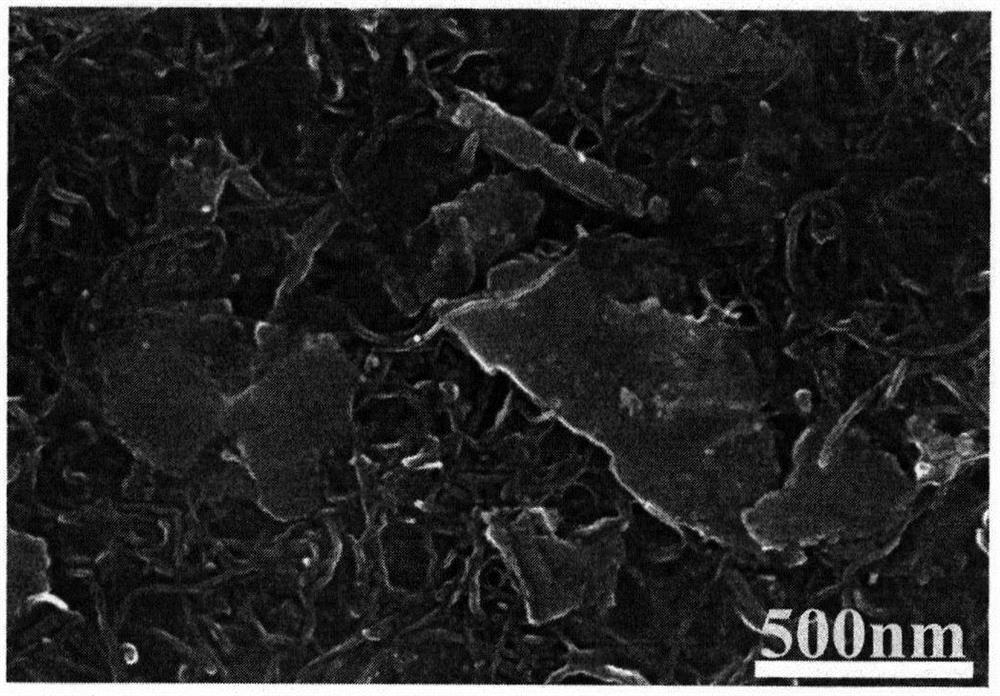

[0035] The conductivity of the graphene / multi-wall carbon nanotube mixed conductive coating (3) is significantly enhanced as the number of conductive coating layers increases within 1 to 3 layers.

[0036] The concentration of the copper paste (4) will affect the overall resistance of the sensor.

[0037] The width of the insulating tape (6) is 0.5cm.

[0038] The preparation method of described a kind of graphene / CNTs flexible pressure sensor is characterized in that, comprises the following steps:

[0039] S1: Mix the prepolymer and the curing agent at a ratio of 10:1, stir well and let it stand still. After the air bubbles escape to the surface of the solution and burst, put it in an electric heating constant temperature blast drying oven at 60°C for about 30 minutes to obtain PDMS.

[0040] S2: Use a microgu...

Embodiment

[0047] Mix 9.1g of prepolymer with 0.9g of curing agent, stir well and let it stand for 20 minutes, pour it evenly on the silicon wafer, put it in an electric heating constant temperature blast drying oven at 60°C for about 30 minutes, and obtain a PDMS film, cut it A thin slice of 3 x 1 cm.

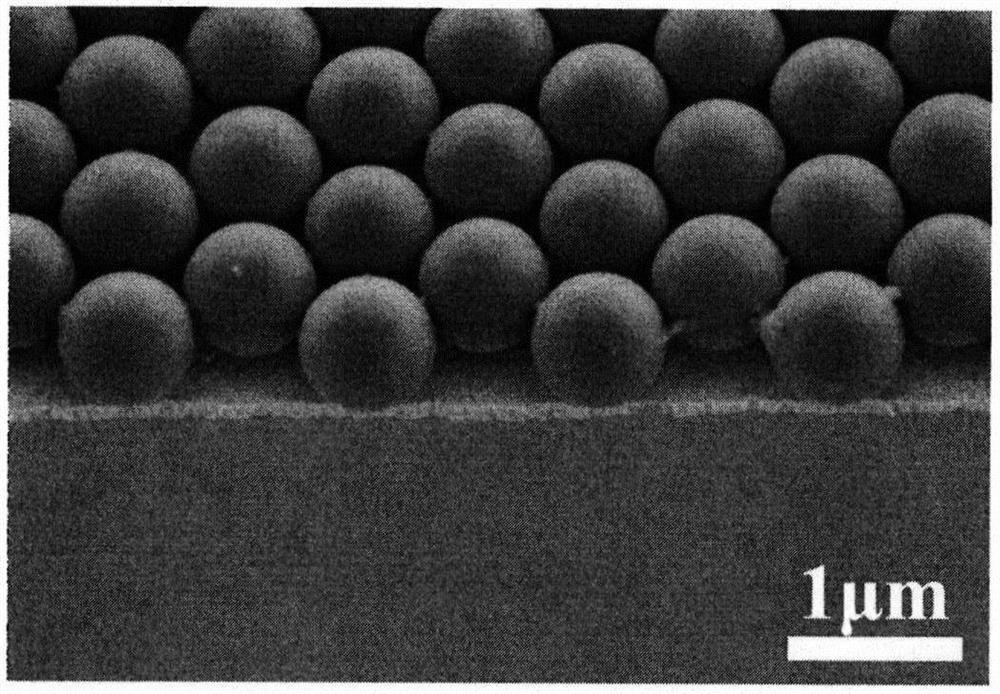

[0048] Take 100 μL of PS microsphere solution with a diameter of 2 μm and 500 μL alcohol in a plastic U-shaped tube, close the U-shaped tube and place it in an ultrasonic cleaner to vibrate for 5 minutes, take 80 μL of the mixed solution and drop it into a sink filled with 1 L of clear water, let The microspheres were free to assemble for 2 minutes, and then dipped a drop of detergent solution with a plastic tube, immersed in the water surface, and gathered the microspheres together to form an orderly and compact array of PS microspheres.

[0049] The PDMS flakes were bombarded with oxygen plasma for 30s to make the surface of the PDMS flakes hydrophilic, then the PDMS flakes were clamped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com