stove burner

A technology for burners and stoves, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of poor secondary air preheating, etc., and achieve the effects of increasing temperature, high safety, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

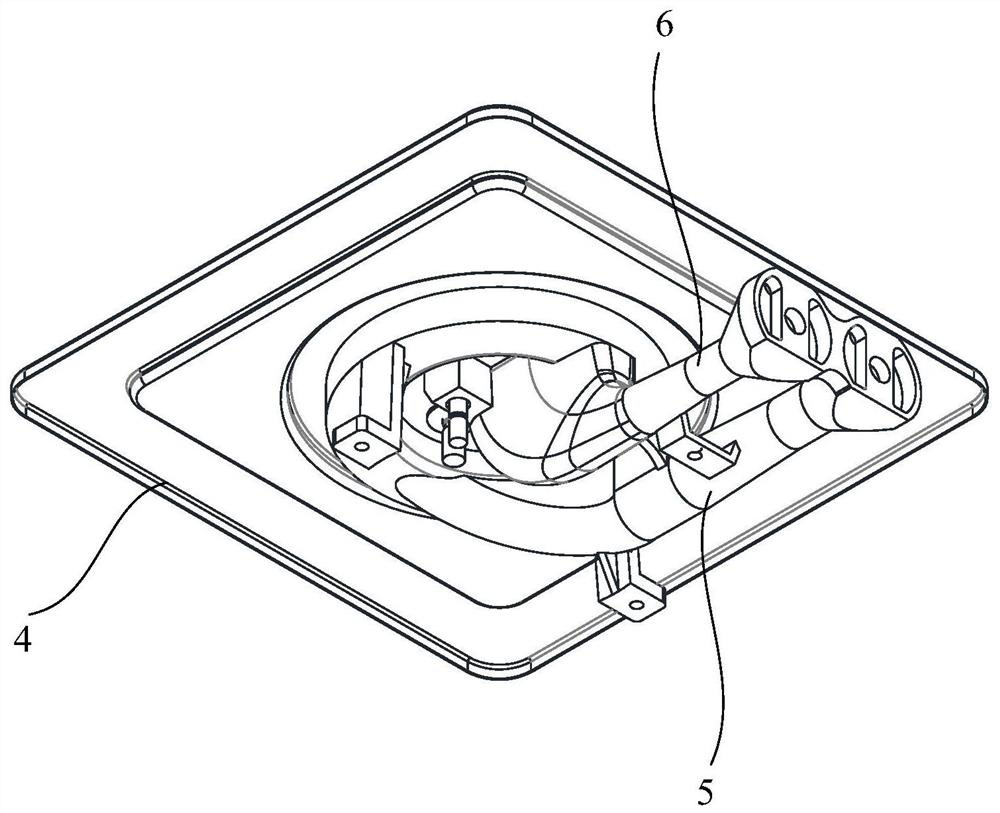

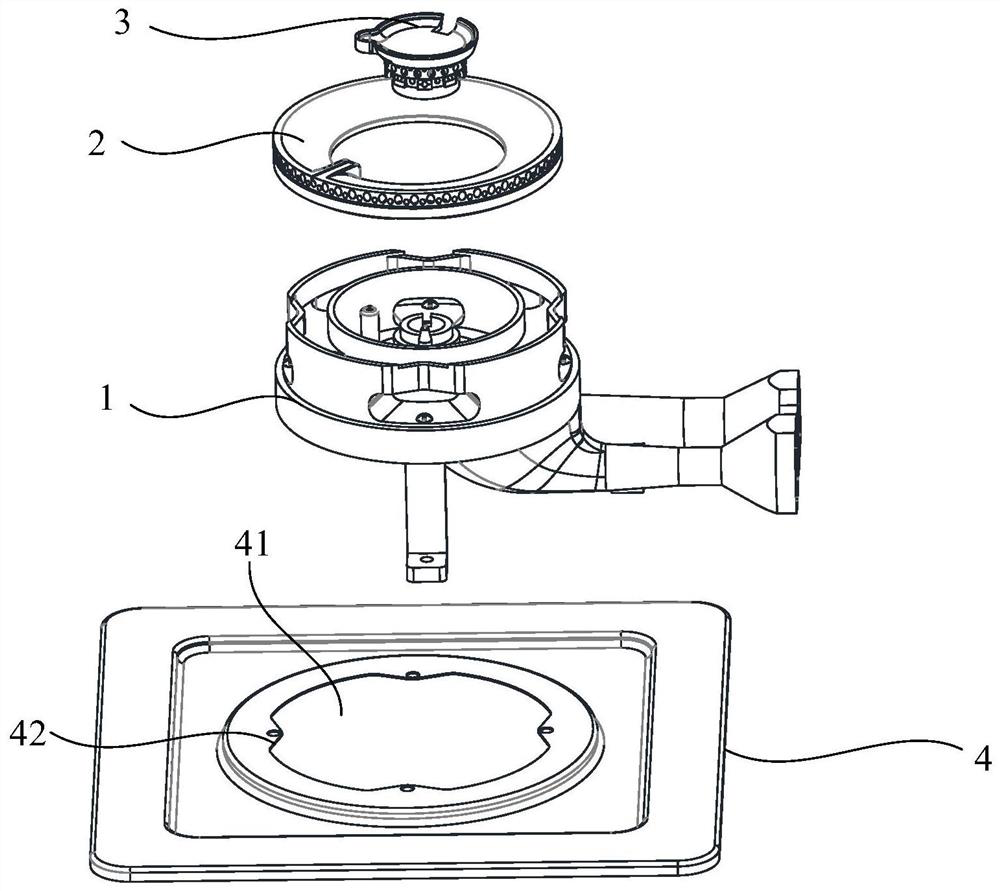

[0058] like Figure 1-Figure 8 As shown, this embodiment discloses a cooker burner, which includes an outer ring fire cover 2 and a base 1 . The outer ring fire cover 2 is set on the base 1 , and the outer peripheral surface of the base 1 is provided with a plurality of inlets 15 of secondary air passages, and the inlets 15 of the plurality of secondary air passages are arranged at intervals along the outer peripheral surface of the base 1 . The outer peripheral surface of the base 1 is also provided with a plurality of grooves 11, the grooves 11 correspond to the entrance 15 of the secondary air passage one by one, and the grooves 11 are located at the entrance 15 of the secondary air passage near the outer ring fire cover 2. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com