Horizontal smoke exhaust device capable of preventing smoke from being sucked through

A smoke exhaust device, a horizontal technology, applied in the direction of valve device, valve operation/release device, balance valve, etc. The effect of sucking through and improving the efficiency of mechanical smoke exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

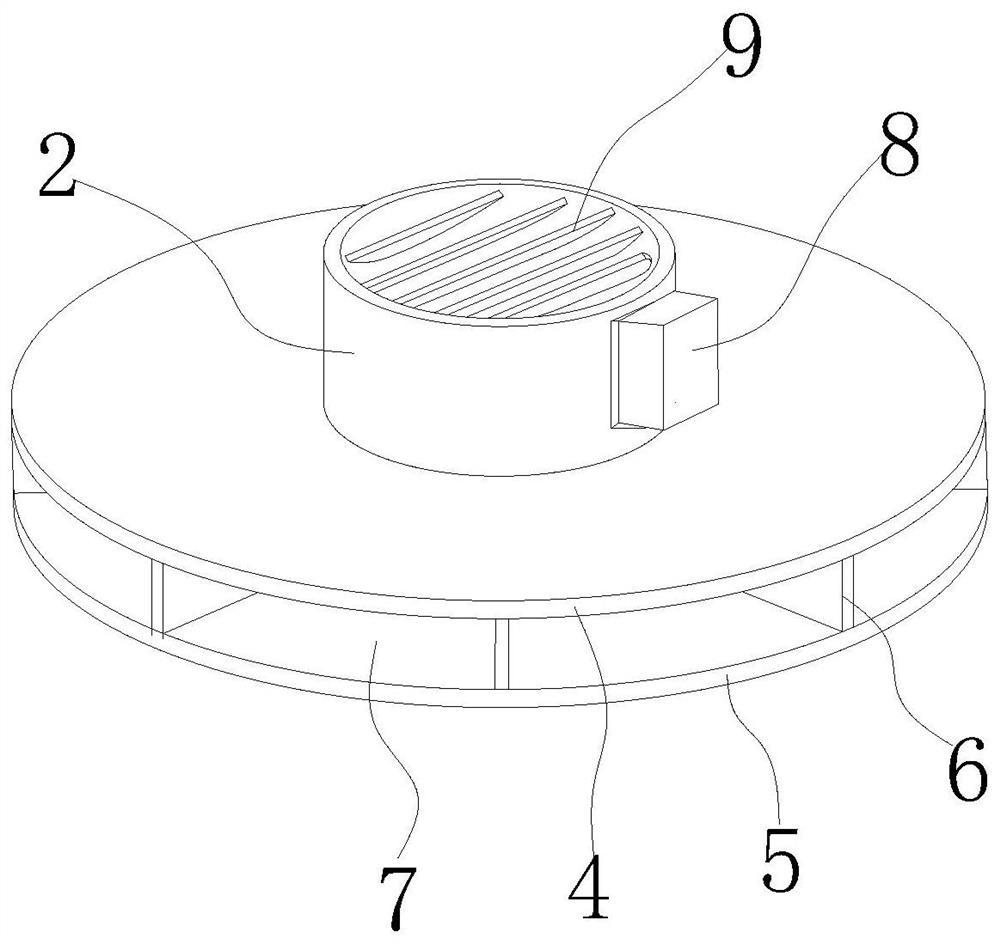

[0025] like figure 1 As shown, the cross section of the short exhaust pipe 2 of this embodiment is circular.

[0026] The ratio of the caliber of the short exhaust pipe 2 to the diameter of the upper cover plate 4 is 1:3.

[0027] The ratio of the caliber of the short smoke exhaust pipe 2 to the vertical height of the guide vane 6 is 2:1.

Embodiment 2

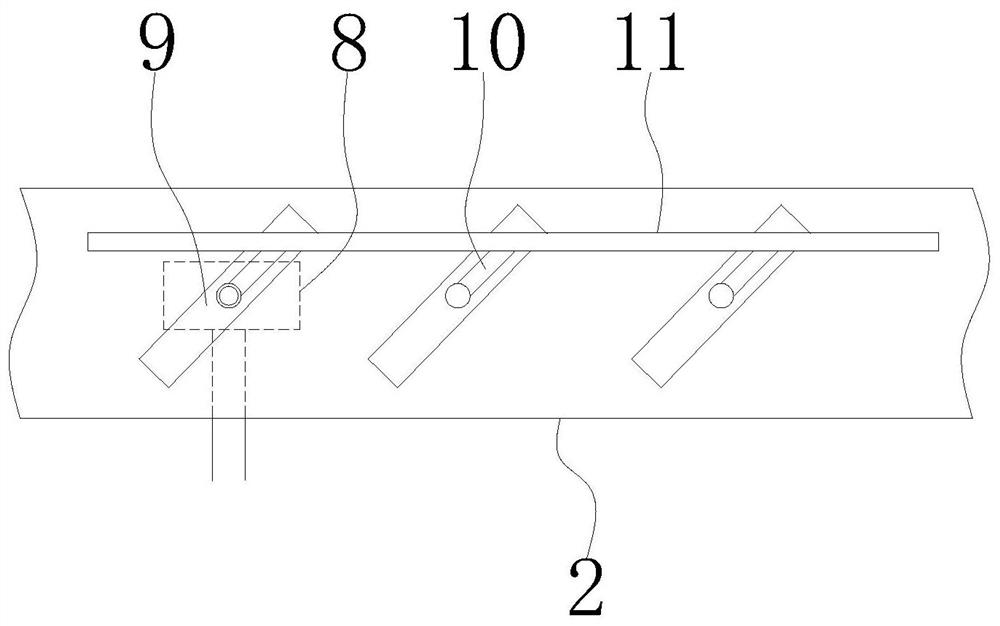

[0029] like Figure 4 As shown, the cross section of the short exhaust pipe 2 of this embodiment is a square. It is suitable for large-scale smoke exhaust short pipe 2, and the smoke exhaust valve 9 in the smoke exhaust short pipe 2 of rectangular cross-section has the same structure and size, which is convenient for installing the smoke exhaust valve 9, and the smoke exhaust efficiency of the smoke exhaust port device is higher.

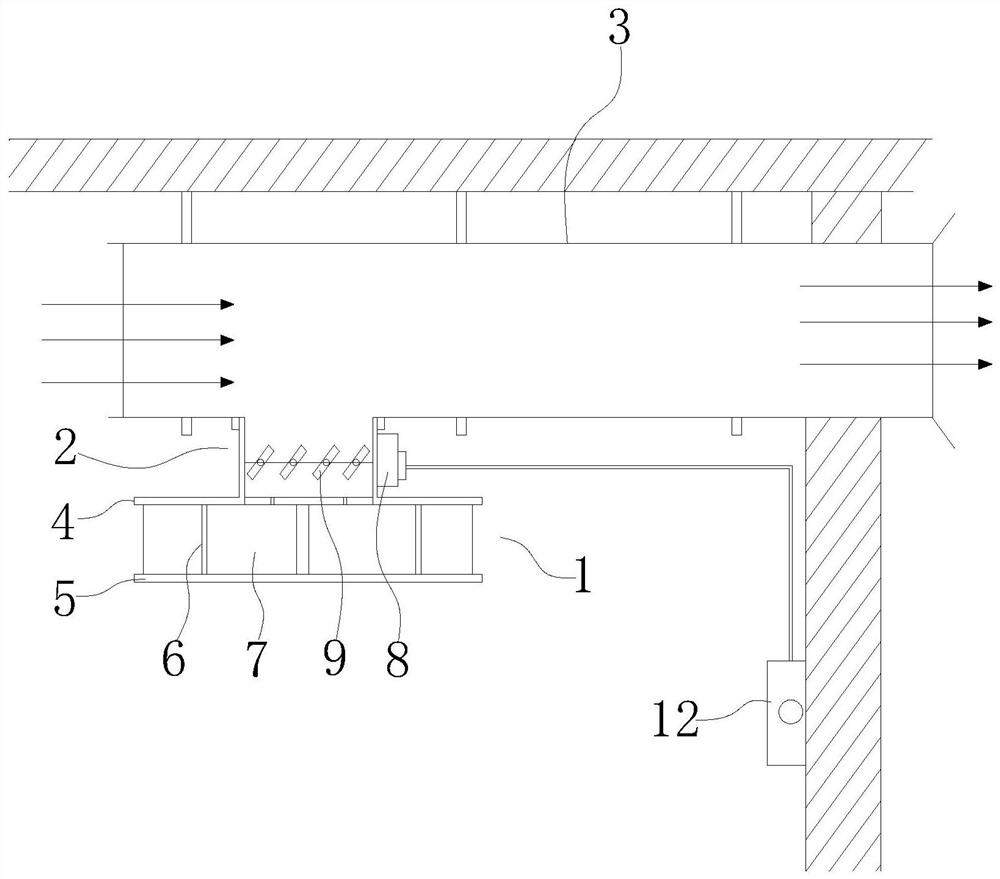

[0030] The rotary motor 8 of the present invention is installed on the outer wall of the short smoke exhaust pipe 2, and the rotary motor 8 is connected with the smoke exhaust valve 9 in the short smoke exhaust pipe 2, and the rotary motor 8 can drive the smoke exhaust valve 9 to rotate. When a fire breaks out, the external fire alarm sends an alarm signal to the control device 12 and the smoke exhaust fan at the outer port of the smoke exhaust pipe 3. After the control device 12 receives the alarm signal, it can drive the rotary motor 8 to work, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com