Device and method for detecting abnormality of tray cover opening and closing mechanism

A technology of switch mechanism and tray cover, which is applied in the direction of electrical components, circuits, semiconductor/solid-state device manufacturing, etc., and can solve problems such as unqualified, scratched semiconductor devices, damaged products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

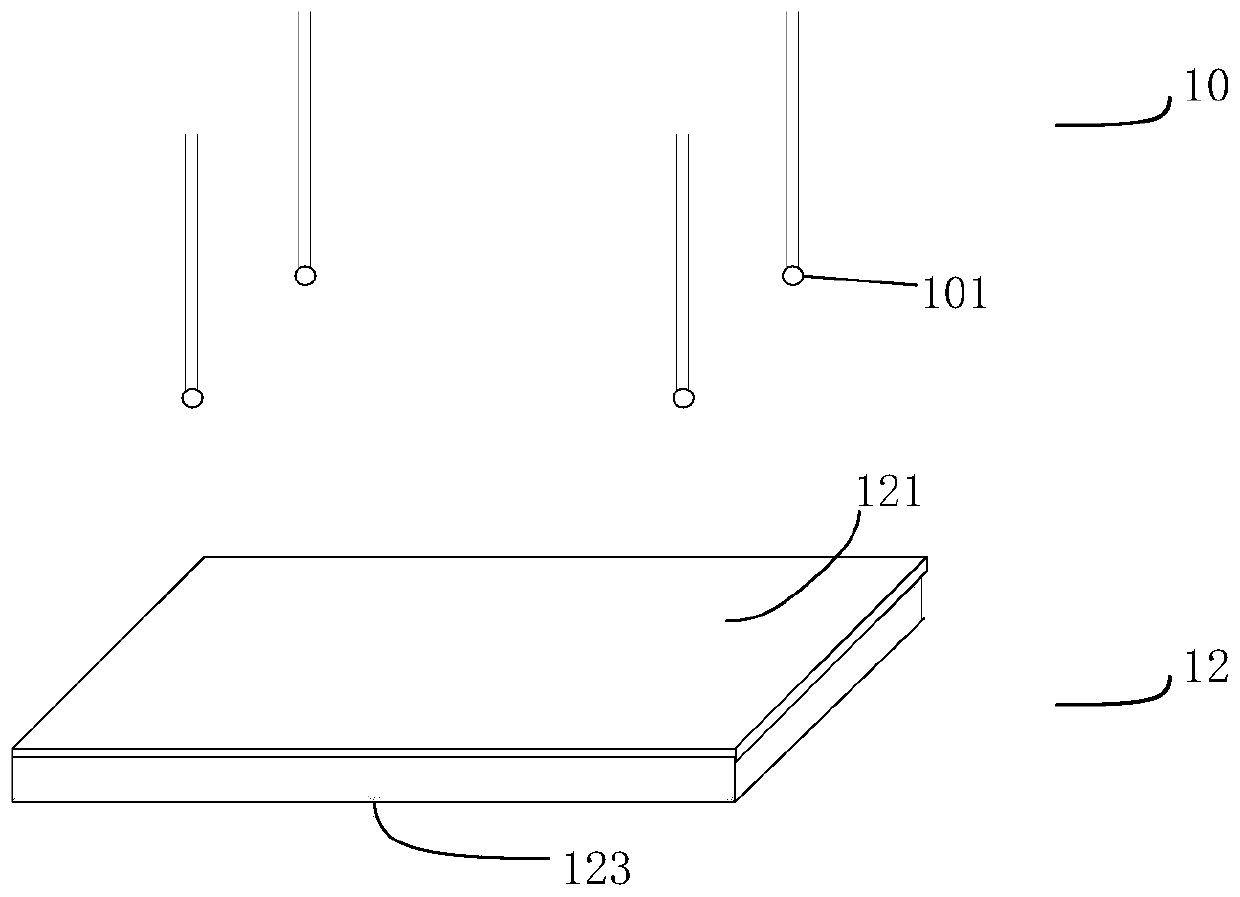

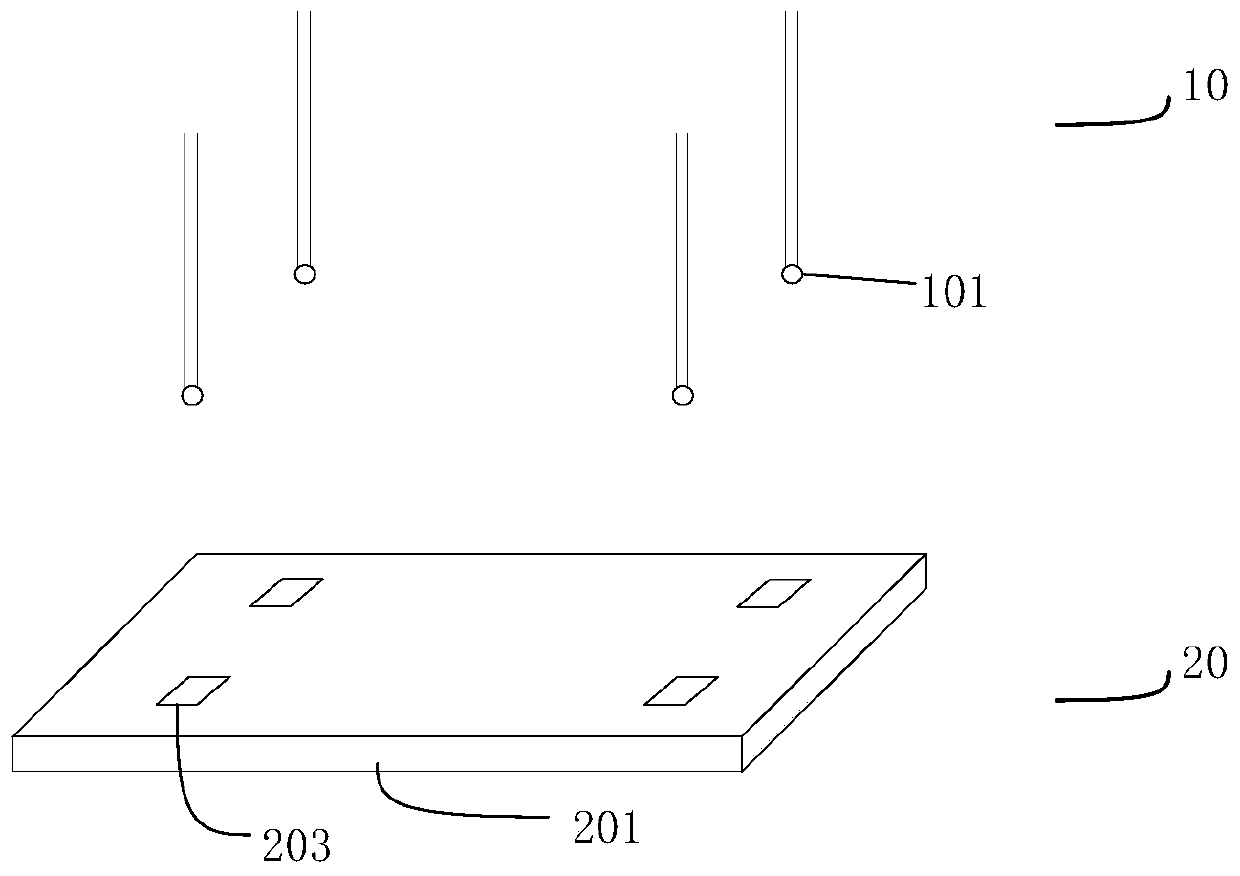

[0060] figure 2 A structural block diagram of a device 20 for detecting an abnormality of a tray lid opening and closing mechanism (hereinafter simply referred to as a detection device) according to an embodiment of the present disclosure is shown.

[0061] Such as figure 2 As shown, the detection device 20 includes a tray lid dummy 201 . In one embodiment, in order to make the simulated scene closer to the real scene, the pallet cover simulant 201 may be set to have the same length and width as the pallet cover 121 . In one embodiment, tray lid dummy 201 is formed to be heavier than tray lid 121 . In one embodiment, the simulation can be achieved by designing a tray lid dummy 201 of a specific thickness.

[0062] Such as figure 2 As shown, the detection device 20 also includes one or more adsorption performance sensors 203 attached to the tray cover simulant 201, for sensing the adsorption performance of each vacuum adsorption member 101 when the tray cover simulant 20...

no. 2 example

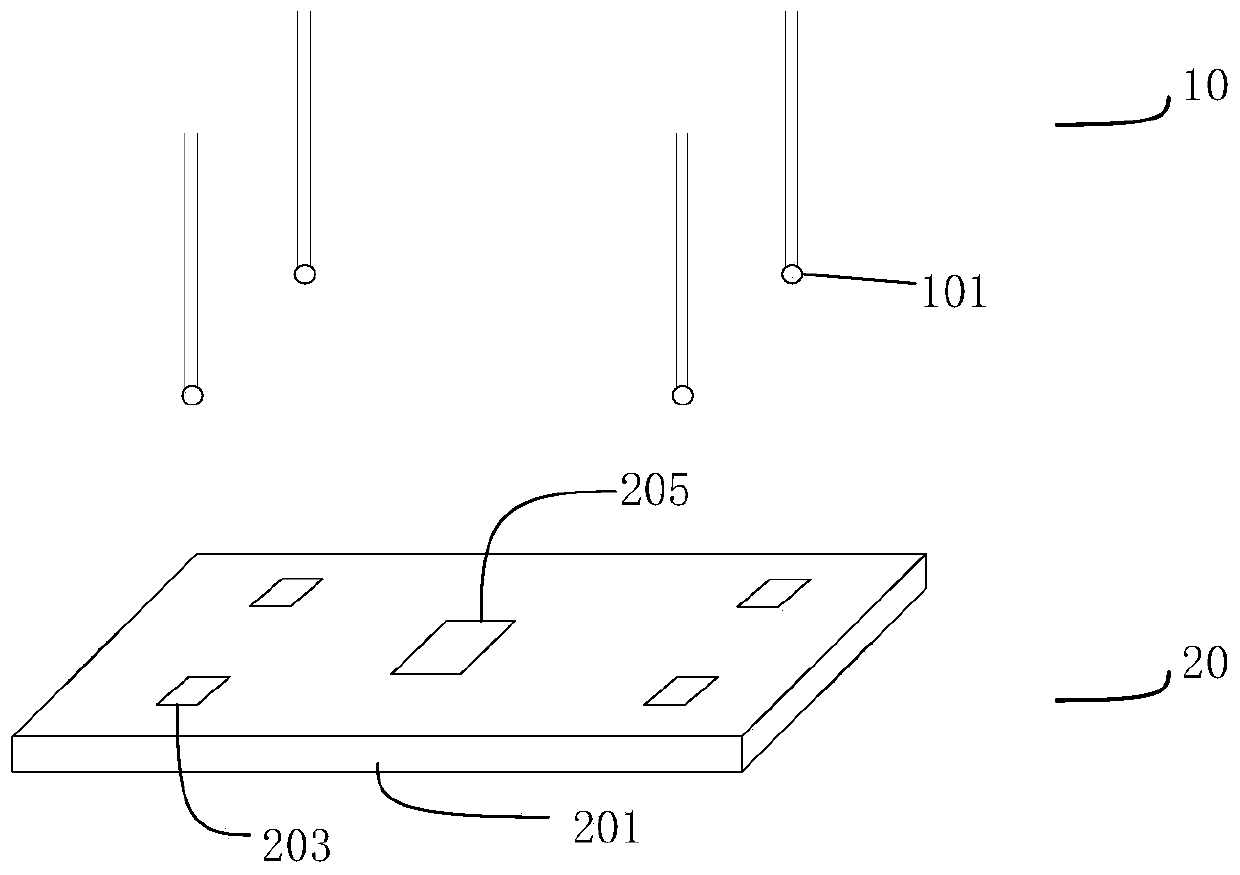

[0081] Figure 5 A structural block diagram of a detection device 20 for detecting an abnormality of a tray cover opening and closing mechanism according to an embodiment of the present disclosure is shown.

[0082] In this embodiment, one or more adsorption performance sensors 203 are movable, and the number and positions of the adsorption performance sensors 203 can be adjusted based on the number and positions of the vacuum adsorption members 101 in the tray lid opening and closing mechanism 10 . In production lines with different configurations and specifications, the number and positions of the vacuum suction components in the tray cover opening and closing mechanism 10 are different. In this case, the number and position of the adsorption performance sensors can be adjusted accordingly based on the number and positions of the vacuum adsorption members 101 in the tray lid opening and closing mechanism 10 by utilizing the movability of one or more adsorption performance se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com