Sliding type air valve

An air valve and sliding type technology, which is applied in the direction of lifting valve, valve device, valve details, etc., can solve the problems of large installation space, no position indication signal transmission, and automatic valve cannot be opened normally, so as to avoid failure and increase Effects of Sensitivity and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

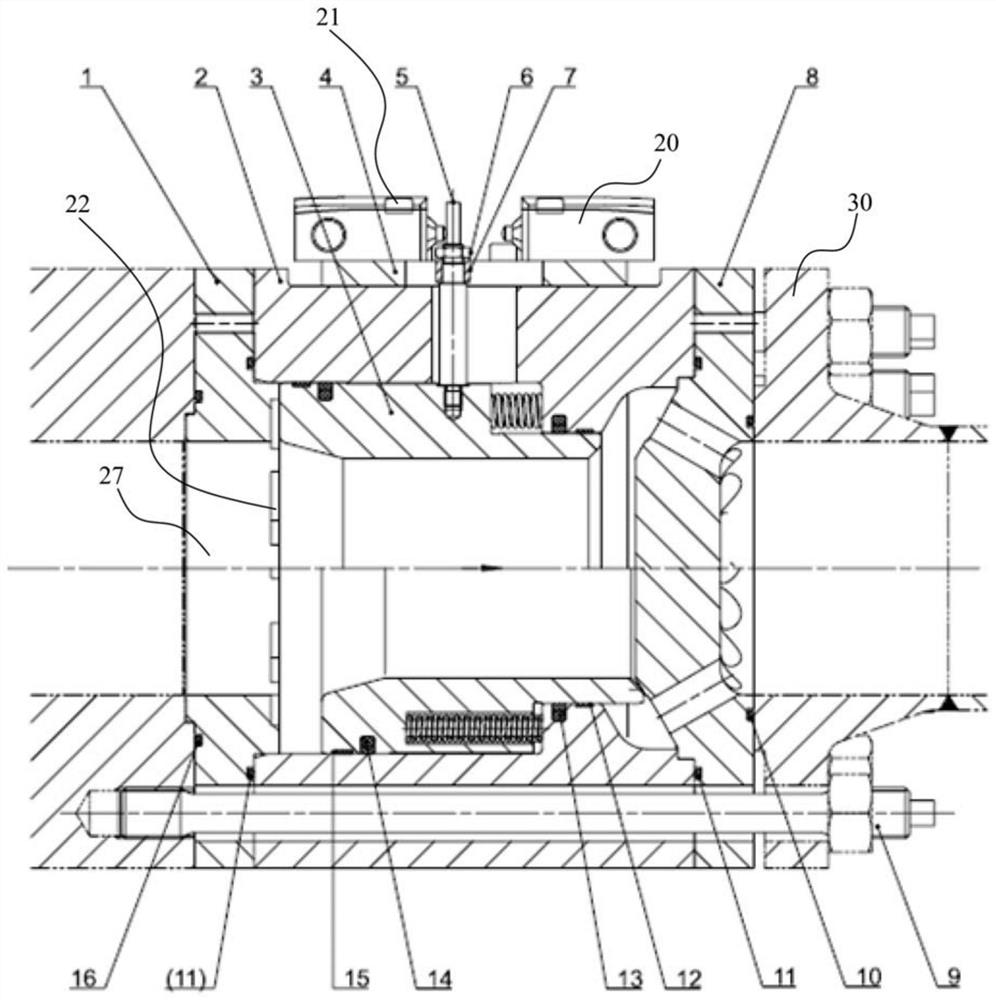

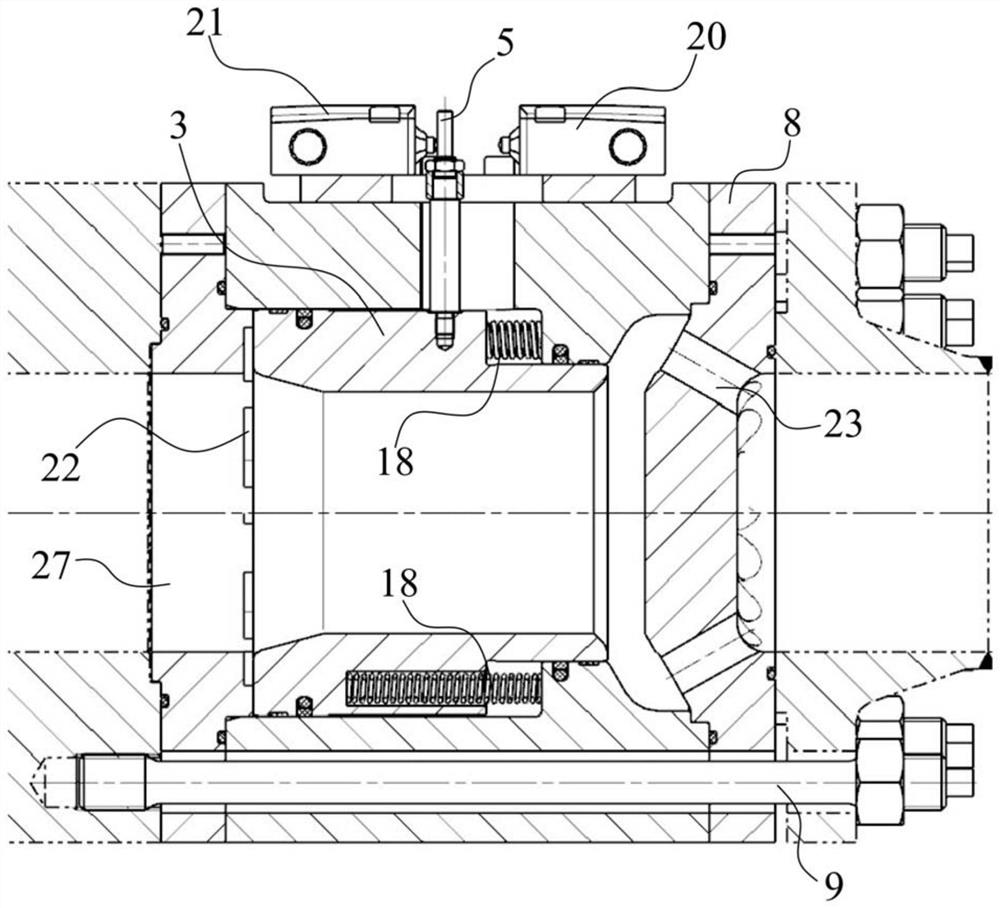

[0033] The sliding air valve provided by the present invention will be described in detail below with reference to the accompanying drawings.

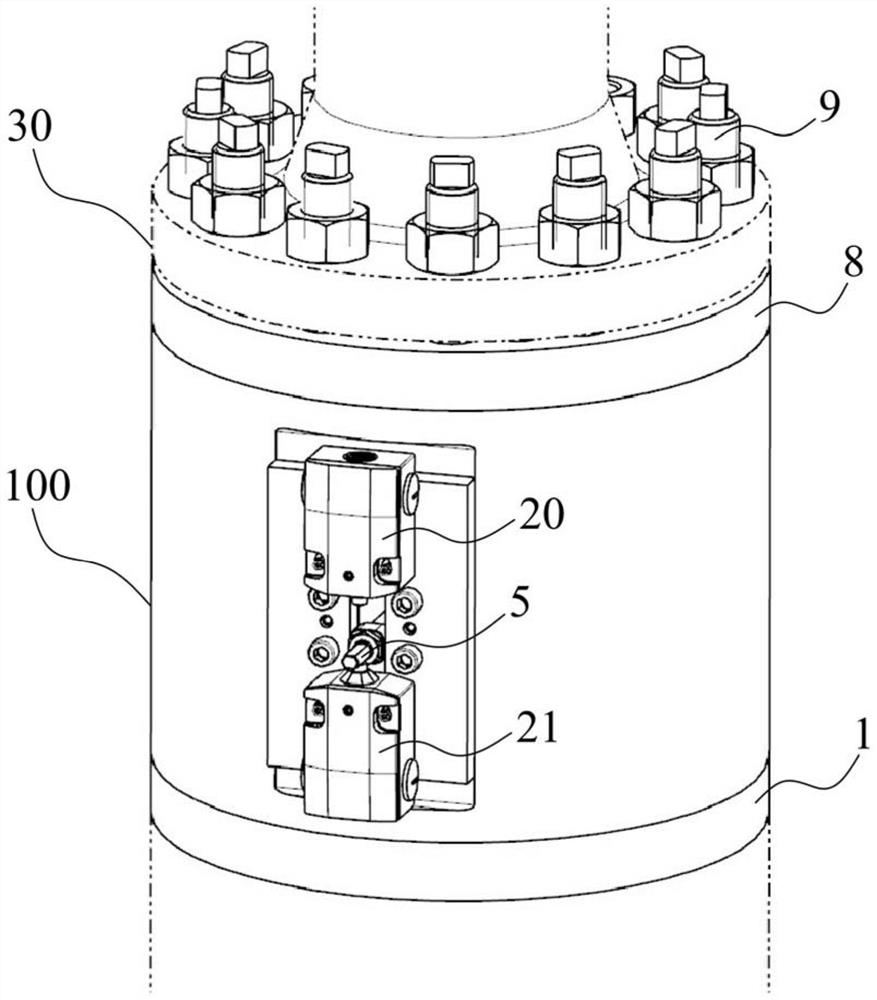

[0034] figure 1 The slide-type air valve 100 according to the invention is shown schematically in an installed state. As shown in the figure, the sliding air valve 100 provided by the present invention has a vertical structure as a whole, and is installed on the water distribution ring pipe of the impact type turbine or the volute drainage and exhaust pipeline 30 of the mixed flow turbine. During the air process, the sliding air valve 100 can be precisely closed and opened.

[0035] As shown in the figure, the position switch is firstly connected to the connecting plate 4 by bolts, and then installed on the valve body 2 as a whole. When pre-assembling in the factory, first install the connecting plate 4 on the valve body, then adjust the positions of the position switches 20 and 21 according to the fully open and fully closed positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com