Thickness construction method and thickness control device for cast-in-place reinforced concrete pouring protective layer

A technology of reinforced concrete and protective layer thickness, which is applied in the direction of buildings, building components, building reinforcements, etc. It can solve the problems of unbalanced force on steel bars, non-infiltration, poor compressive strength of plastics, etc., and achieve stable laying positions of steel bars. The method is simple and the effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further limited below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the descriptions made.

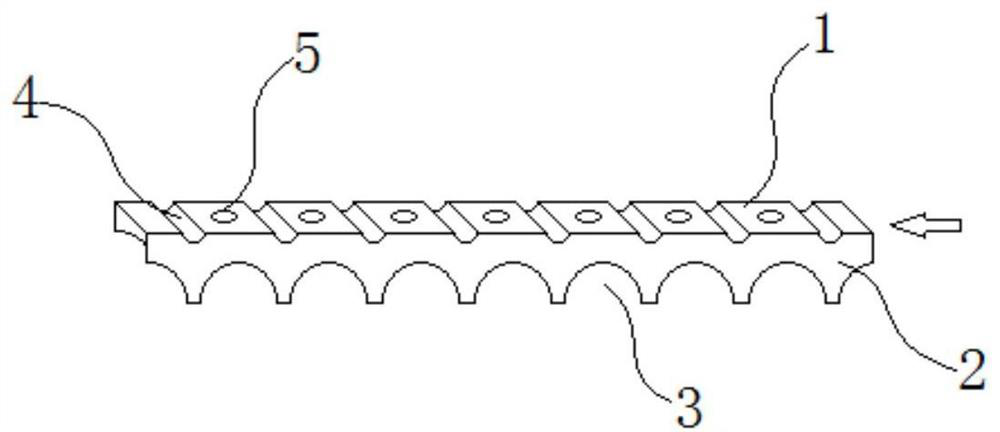

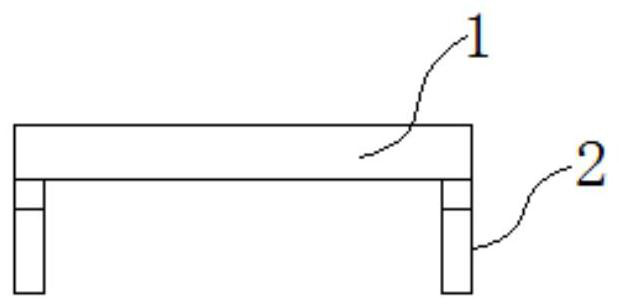

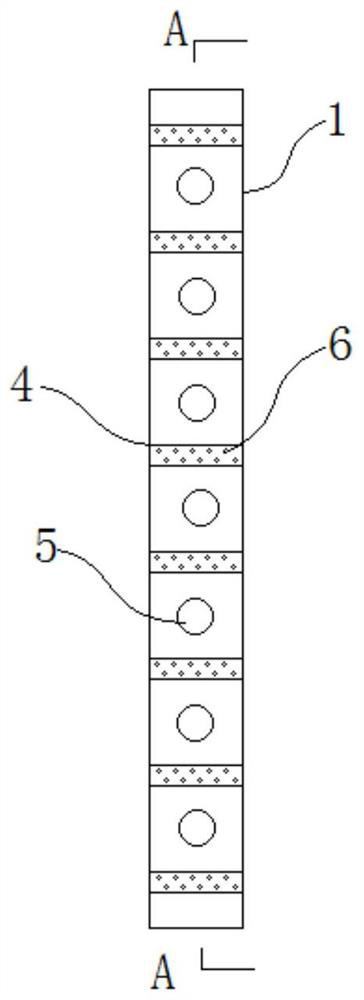

[0036] Such as figure 1 and figure 2As shown, in this embodiment, in order to solve the problem that the steel slab surface in the prior art tends to slide during the pouring process, the pre-laying position of the steel bar will change, which will affect the overall mechanical performance of the slab surface. At the same time, the traditional thickness control device is adopted After the reinforced slab is supported, the amount of concrete poured into the thickness control device is low, and even the interface between the thickness control device and the concrete is not close, resulting in voids on the poured concrete slab, which affects the overall endurance strength of the concrete cover : a device for controlling the thickness of the cast-in-plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com