Method for preparing shape-adjustable polyion liquid-based anisotropic composite particles based on seed polymerization method

A technology of polyionic liquid and ionic liquid, applied in the field of preparation of polyionic liquid-based anisotropic composite particles, can solve problems such as convenient regulation, limitation of particle application range, inability to realize particle morphology, etc. effect of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 ionic liquid monomer

[0027] The synthetic reaction formula of ionic liquid monomer is as follows:

[0028]

[0029] Preparation method: uniformly mix 2.0 g of [MTMA]Cl aqueous solution with a concentration of 75% and 2.3 g of Li[TFSA], stir at room temperature for 12 hours, anion exchange reaction occurs, and the obtained reaction solution is divided into upper and lower layers, and the lower layer of ionic liquid is removed Add a small amount of deionized water to it and continue to stir and wash it. After repeated five times, put it in a vacuum drying oven and dry it at 50 °C for 24 hours to obtain a colorless and viscous ionic liquid monomer ([MTMA][TFSA]).

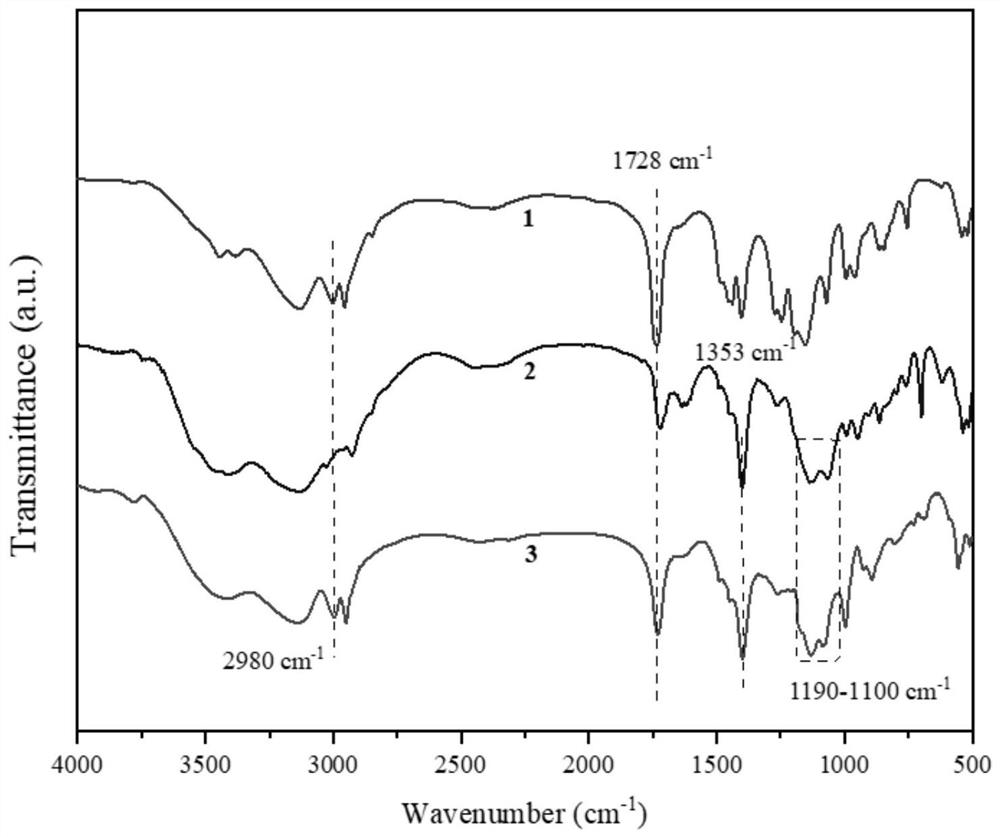

[0030] Such as figure 1 as shown, figure 1 Middle 2 is the infrared absorption spectrum of the ionic liquid monomer ([MTMA][TFSA]). It can be seen from the infrared absorption spectrum of the synthesized ionic liquid monomer that the 1728cm -1 is the stretching vibration ...

Embodiment 2

[0031] The preparation of embodiment 2 PMMA polymer seed ball

[0032] Methods as below:

[0033] Purification of MMA: Methyl methacrylate (MMA) monomer is slowly passed through Al 2 o 3 The filter column, and the colorless and transparent MMA monomer obtained by filtering off the polymerization inhibitor at the outlet of the filter column lower end is collected with a brown sample bottle for use.

[0034] Weigh 0.1g of PVP, disperse it in 60mL of deionized water, add 5.0g of purified MMA monomer to it, after ultrasonic emulsification is complete, transfer the system to an oil bath and start to heat up. During the heating process, a total of 10 mL of KPS aqueous solution (1 wt%) was added twice at 50° C. and 85° C. respectively, and finally stabilized at 100° C. for 2 hours to complete the polymerization process. After the reaction, centrifuge to take the lower layer product, add 20mL water to it and ultrasonically disperse evenly, then centrifuge, pour out the upper layer so...

Embodiment 3

[0037] The preparation of embodiment 3 PMMA polymer seed balls

[0038] Methods as below:

[0039] Purification of MMA: Methyl methacrylate (MMA) monomer is slowly passed through Al 2 o 3 The filter column, and the colorless and transparent MMA monomer obtained by filtering off the polymerization inhibitor at the outlet of the filter column lower end is collected with a brown sample bottle for use.

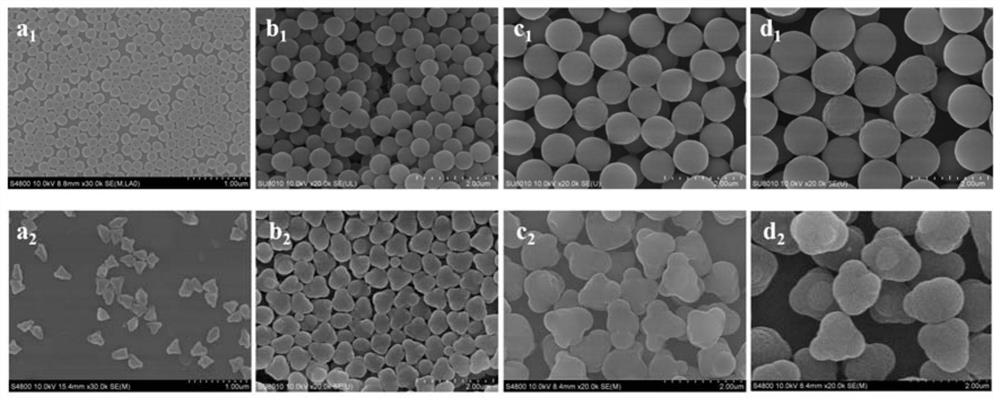

[0040] Take by weighing 0.3g PVP respectively, then join respectively in the reaction solvent that the total amount that methanol and deionized water form is 60mL, wherein the volume ratio of methanol and deionized water is respectively 1:1 (methanol / deionized water 30.0mL / 30.0mL), 5:3 (methanol / deionized water 37.5mL / 22.5mL) and 7:3 (methanol / deionized water 42.0mL / 18.0mL), ultrasonically disperse it completely. 3.0 g of purified MMA monomer and 30.0 mg of AIBN were added thereto. The whole system was subjected to three cycles of vacuum pumping and nitrogen blowing, and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com