Piled plate lifting baffle protection device and control method thereof

A technology of lifting baffles and protective devices, which is applied to conveyor control devices, stacking, transportation and packaging of objects, etc., can solve the problem of not avoiding strong collision between baffles and steel plates, prolong service life, and eliminate impact noise. , to avoid the effect of strong impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

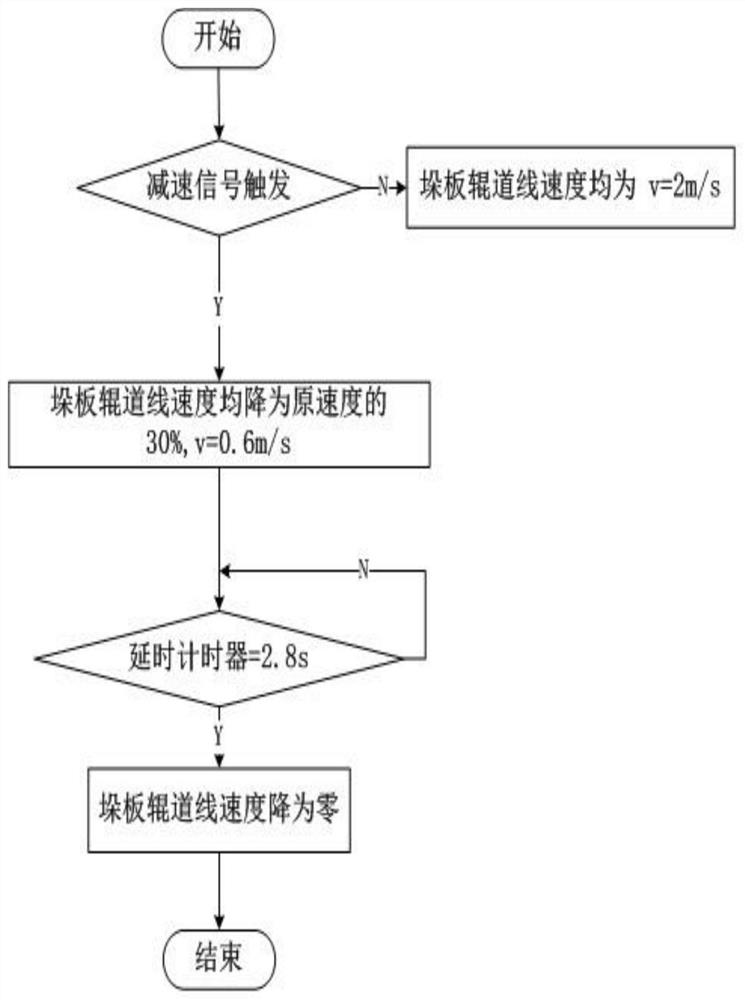

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail now in conjunction with accompanying drawing.

[0021] Such as Figure 1-2 , a pallet lifting baffle protective device, comprising a pallet lifting baffle 1 and a pallet roller table 2, the pallet lifting baffle 1 is located at the end of the pallet roller table 2, and a roller table is also arranged on the pallet roller table 2 The cover plate 3 and the roller table cover plate 3 are provided with a rectangular opening 31. The rectangular opening 31 is located at a distance of 3m from the lifting baffle of the stacking plate. A photoelectric switch 5 installed on the photoelectric switch bracket 4 is arranged above the rectangular opening 31. The rectangular opening 31 The size is 60mm*70mm.

[0022] Pallet lifting baffle plate 1 is a swing lifting mechanical baffle plate, which has the functions of damping buffer and spring reset. The lifting mechanism uses a hydraulic cylinder to push the swing arm to lift, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com