Plastic tank water treatment equipment

A technology for water treatment equipment and tanks, applied to underwater structures, containers, packaging, etc., can solve the problems of non-recyclable, affecting equipment life, low production efficiency, etc., to prevent outward expansion or inward shrinkage, The effect of ensuring safety strength and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

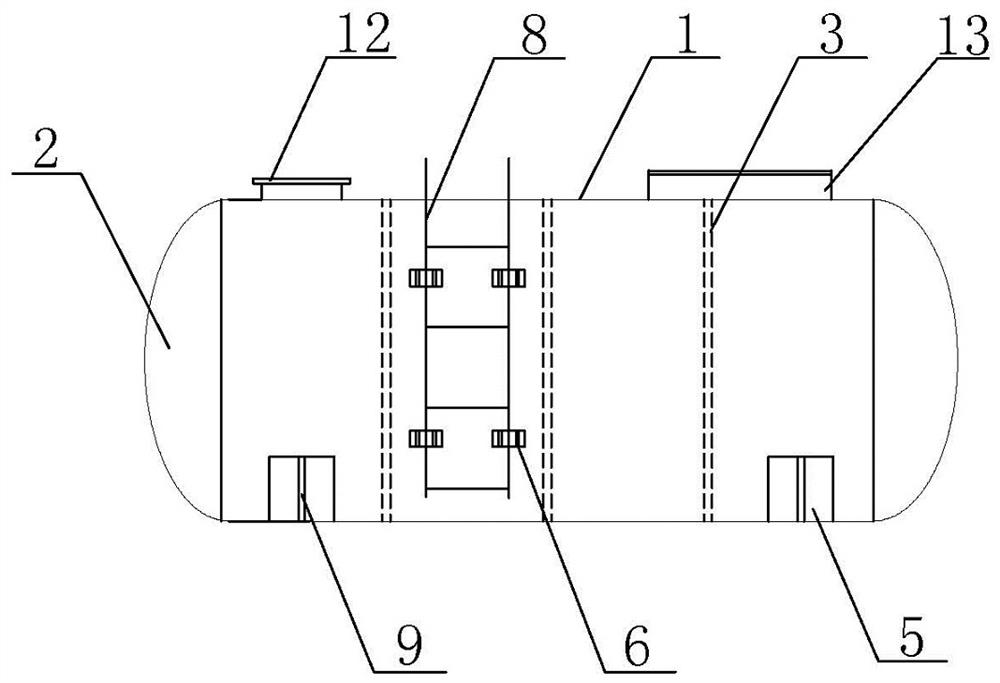

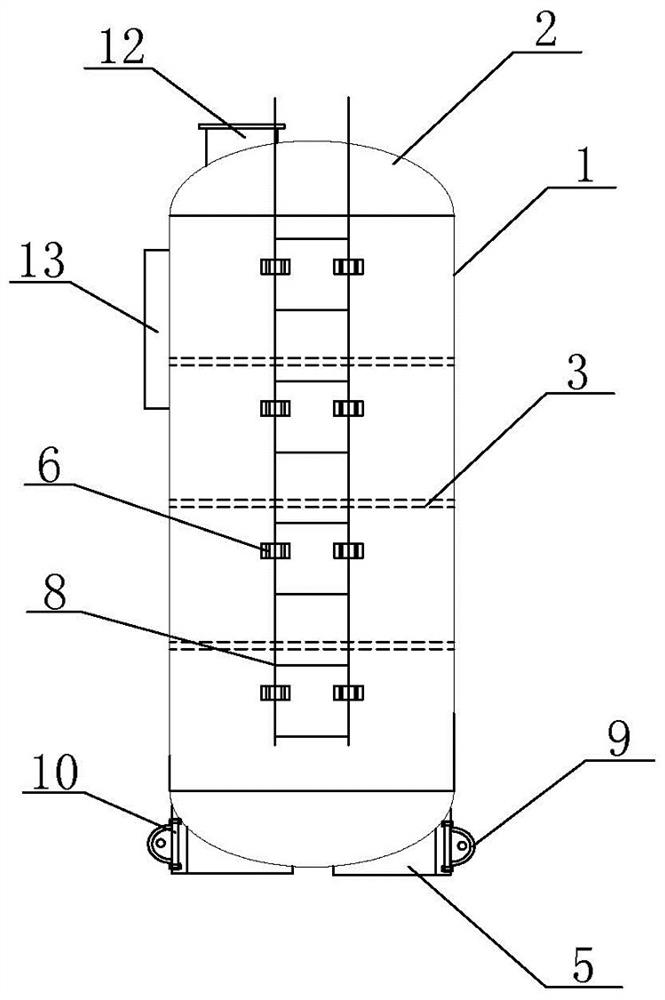

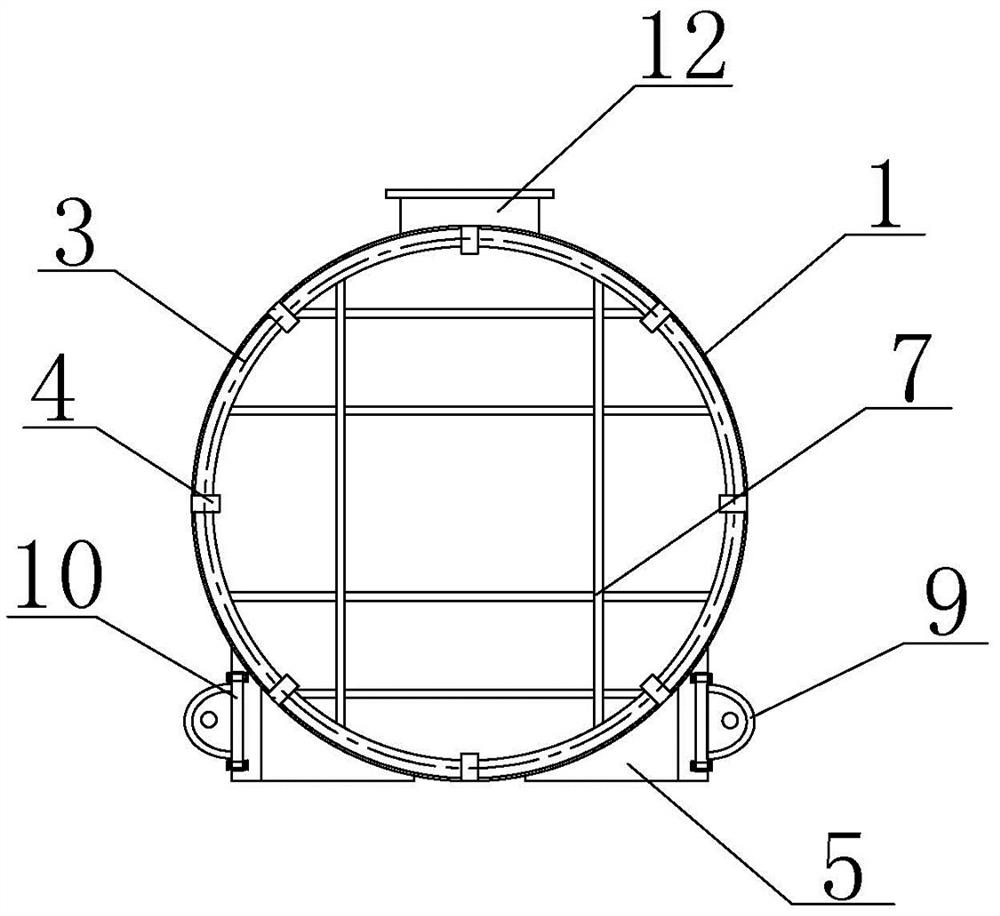

[0026] Such as Figure 1-5 As shown, the present invention includes a tank body 1. The material of the tank body 1 is PPH raw material or HDPE raw material. The PPH raw material and HDPE raw material have the characteristics of heat setting, creepability, high tension, no cracking and no toxicity. When personnel use PPH raw materials or HDPE raw materials to make the tank body 1, they can be directly wound on various types of molds for integral molding, which not only has high production efficiency but is also very environmentally friendly.

[0027] The two ends of the tank body 1 of this equipment are fixedly connected with the head 2, wherein the head 2 is fixedly connected with the two ends of the tank body 1 by fusion welding; the fusion welding process is used to fuse the connection ends of the tank body 1 and the two heads 2 Together, the tank body 1 and the head 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com